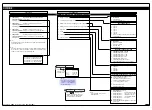

7

2 February, 2005 Code Sheet V4.01d (NZ1001)

0 Functions Activated

by Pressing the

PROGRAM Button

1 Calibration

Procedures

2 Related Calibration

Functions

3 -

CALIBRATION MODES FOR INPUT AND OUTPUT

FIRST DIGIT

SECOND DIGIT

0 Serial Communications

Properties

1 Set Auto Zero Maintenance

for 3rd digit

2 Set Averaging Samples &

Averaging Window for 3rd

digit

3 Totalizer Settings Mode

4 Setup 32-point

Linearization Tables

5 Scale Analog Output

LOW/HIGH Scale Range

Settings

6 -

7 -

See Page 6 for a break-

down of the sub-menu

See Page 6 for a break-

down of the sub-menu

OBJECT FOR 2nd DIGIT

THIRD DIGIT

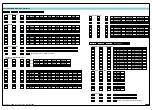

Auto zero capture band

Use

buttons to set

AZ_APT from

0 to 65535

counts

Auto zero motion

Auto zero aperture window

Use

buttons to set

AZ_CAP from 1 to 254 counts

Use buttons

to

set averag-

ing samples from 0 to 255 counts

Use

buttons to set averaging

window from 0 to 65535 counts

Rate-of-change in counts per second

Use buttons

to

set LOW display reading

[CAL_L]

Use

buttons to set

HIGH display reading [CAL_h]

Select the method of configuring the user defined

linearization table:

manual

or

auto

setup mode.

Then set the table number, date, and serial number

before setting the linearization points. Or select [init]

to re-initialize the default table settings.

Note:

The input channel setting in

the 3rd digit is

not

relevant to

the

manual setup mode

.

Note:

The correct input signal channel must be

selected in the 3rd digit when configuring a lin-

earization table using the

auto setup mode

.

0

-

1

CH1

2

CH2

3

CH3

4

CH4

5

CH5

6

CH6

7

CH7

THIRD DIGIT

THIRD DIGIT

THIRD DIGIT

Use

buttons to set

AZ_MOT from

0 to 255 counts

Use

buttons to set time period

Use

buttons to set

total from 1 to

65535

Default setting 10,000 counts

Use

buttons to set

Cutoff from –19999 to 32767

Use buttons

to

set rollover to ON or OFF

Use

buttons to set input rate

Use

buttons to select mode

Use

buttons to set parity

Use

buttons to select baud rate

Use

buttons to set address

Modbus RTU protocol

Macro controlled serial output

Print directly to serial printer or PC

Ethernet

DeviceNet

Touchpanel

Modbus master

Up to 255

Select the settings for the seri-

al port selected in the 3rd digit

THIRD DIGIT

Use

buttons to select source for totalizer

Use

buttons to select source for analog output

For data source selection options, see

Select Data Source

diagram on Page 8

For data source selection options, see

Select Data Source

diagram on Page 8

0

Result

1

Channel 1

2

Channel 2

3

Channel 3

4

Channel 4

5

Channel 5

6

Channel 6

7

Channel 7

THIRD DIGIT

0

-

1

Port 1

2

Port 2

3

Port 3

Note: Port 3 only

available on certain

input modules

These settings show the full

range of the baud rate.

The available baud rate differs

for ports 1 to 3.

0

-

1

Total 1

2

Total 2

3

Total 3

4

Total 4

5

Total 5

6

Total 6

0

-

1

Analog Output 1

2

Analog Output 2

3

Analog Output 3

4

Analog Output 4

5

Analog Output 5

6

Analog Output 6

7

Analog Output 7

Note: Settings 3-7

not available at

present