Greenlee / A Textron Company

4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

7

EK622LX Battery-powered Crimping Tool

Operation

(cont’d)

Pressure Sensor

This tool is equipped with a pressure sensor that alerts

the user of an incomplete crimp.

• If the tool is manually retracted before completion of a

crimp, the red LED and an audible beep will be active

for 2 seconds.

• If the tool is unable to reach the required crimp force,

the red LED, work light, and an audible beep will pulse

until after the trigger is released.

Installing K22, KA22, and KC22-type Dies

1. Select the proper dies for the intended crimp.

2. Push the die release button.

3. Slide the die into the crimping head until it “snaps”

into place.

4. Properly position the second die. Repeat steps 2

and 3.

Installing W-type Dies

1. Push the die release button.

2. Slide the die adapter (Greenlee part number

50042920) into crimping head until it “snaps” into

place.

Note: The die adapters have the “D

3

” die profile.

No additional dies are needed if the connector to be

crimped requires a “D

3

” die.

3. Repeat for the other adapter.

4. Select the proper dies for the intended crimp.

5. Press the locking flange and open the crimping

head.

6. Push the W-type die detent and slide the W-type die

into place.

7. Properly position the second die. Repeat steps 5

and 6.

Preparing Cable

Follow the lug manufacturer’s instructions for appropri-

ate cable strip length.

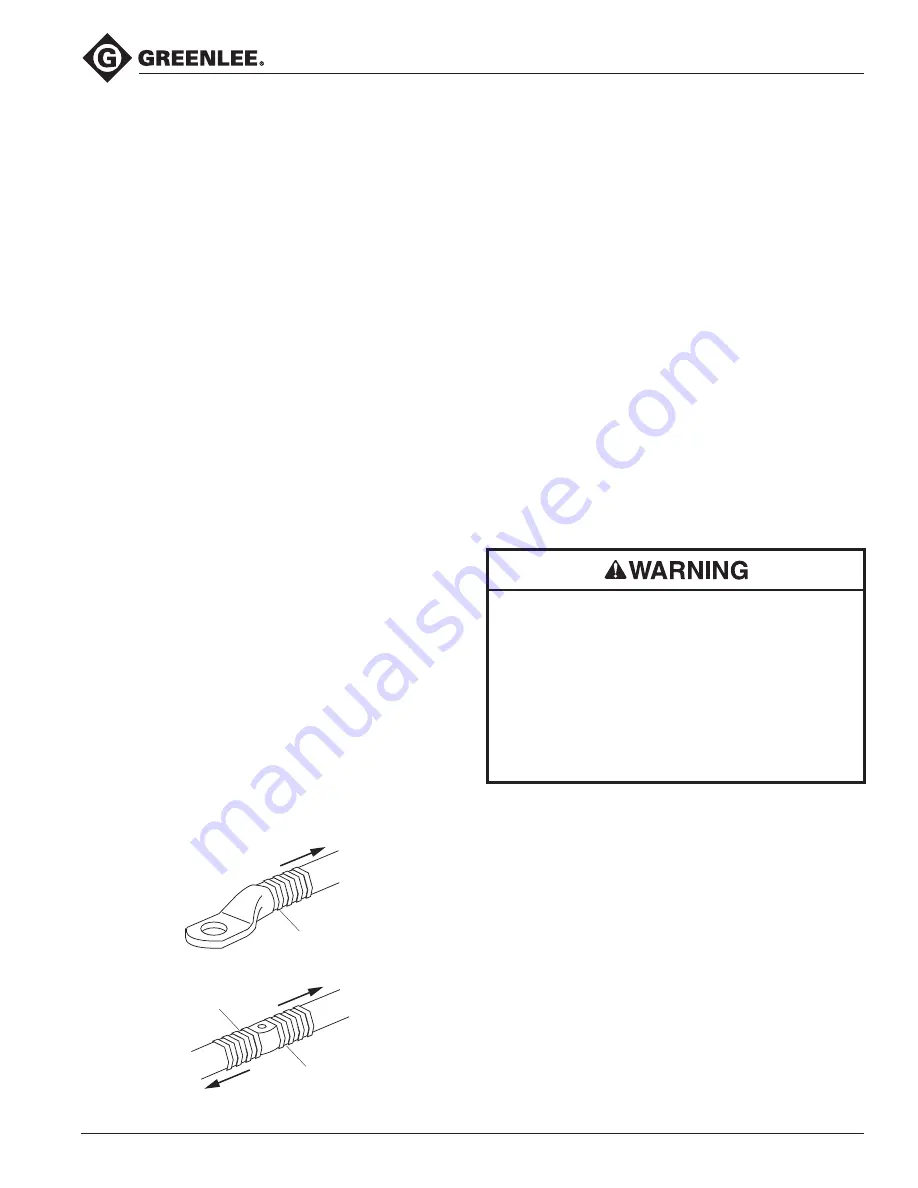

Crimping Direction

(evenly spaced)

First Compression

Crimping Direction

SIDE A

(evenly spaced)

Crimping Direction

SIDE B

(evenly spaced)

First Compression

SIDE A

First Compression

SIDE B

Crimping Cable

1. Press the locking flange and open the crimping

head.

2. Insert the properly assembled connector into the

crimping head.

3. Close the crimping head.

4. Pull the trigger to make the crimp.

5. Hold the trigger down until the crimping tool

achieves pressure relief and the ram retracts.

6. The crimping tool returns automatically.

7. Position the crimping tool for next crimp. Repeat

Steps 4 through 6 for the number of crimps as

described in this manual.

8. Open the crimping head and remove the connector.

Notes: If it is necessary to retract the ram before a

crimping cycle is completed, push the retract button.

Pushing the retract button will result in the complete

retraction of the ram.

After completing the last crimp with W-type dies on an

aluminum connector, wipe off the excess oxide inhibitor.

An incomplete crimp can cause a fire.

• Use proper die, connector, and cable combinations.

Improper combinations can result in an incomplete

crimp.

• The relief valve sounds and the ram automatically

retracts to indicate a completed crimp. If you do not

hear the sound of the relieve valve or the ram does

not automatically retract, the crimp is not complete.

Failure to observe these warnings could result in

severe injury or death.