EK622PLT and EK622PLX Battery-powered Crimping Tools

Greenlee / A Textron Company

4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

9

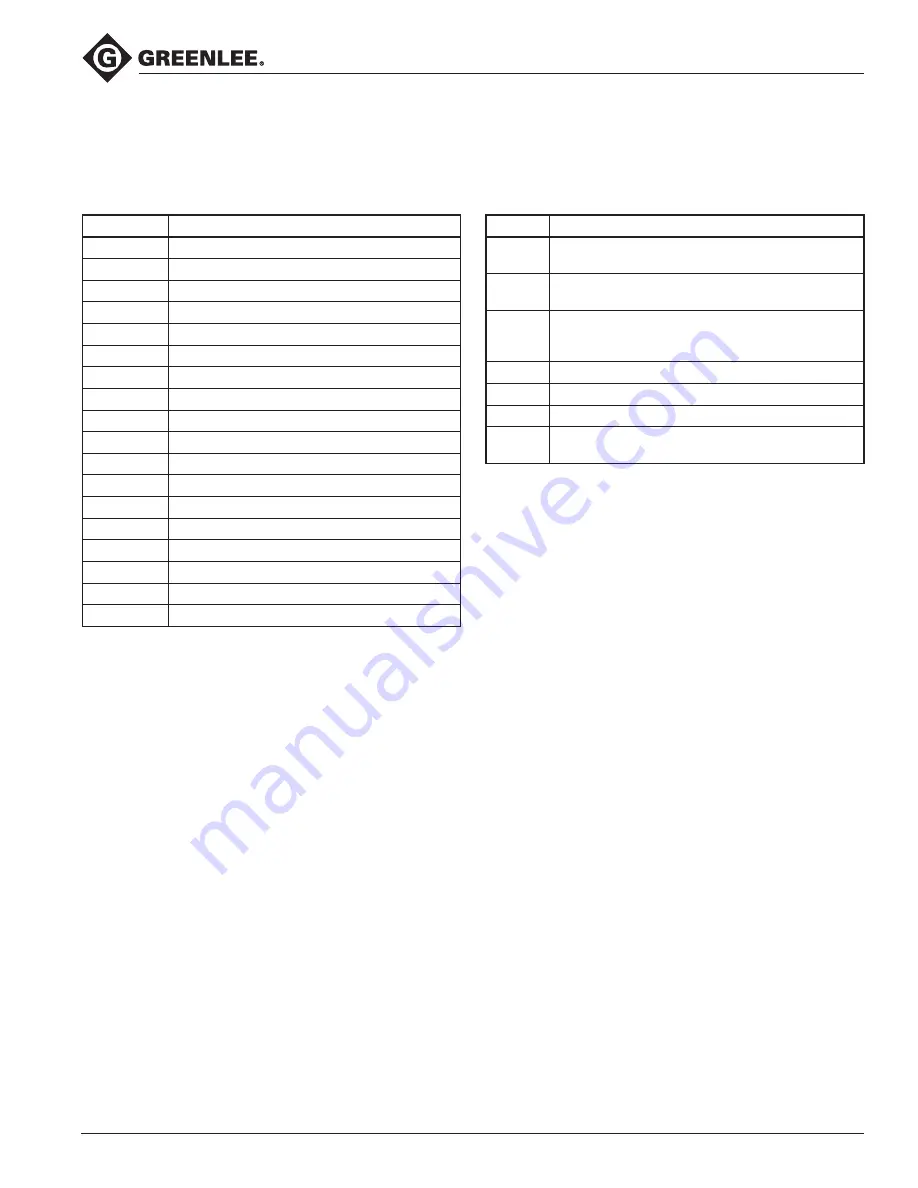

LCD Screen

This tool has an LCD screen, which displays informa-

tion about the tool. Turn on the screen by inserting the

battery and jogging the tool. If there are any problems

with the tool, an error code appears.

Error Code Meaning

1

Overcurrent fuse

2

Overcurrent comparator

3

Overheated circuit board

4

Overheated battery

5

Battery empty; operation stops

6

Faulty crimp; complete cycle

7

Faulty crimp; incomplete cycle

8

Low battery

9

Battery empty; tool won’t run

10

Real-time clock battery low

11

Tool deactivated

12

Service necessary

13

Real-time clock not found

14

Bluetooth

®

unit not found

15

Mobile unit not found

16

Pressure sensor not found

17

Burst pressure exceeded

18

Battery temperature too low

If there is no error code, cycle through the various

displays using the left and right buttons on either side of

the screen. There are seven displays in total.

Display Information Shown

1

Bluetooth

®

status, battery charge, current

pressure, max. pressure

2

Firmware, available firmware update,

serial number

3

Current user. Press and hold both buttons to

change user, select with right button, and confirm

by jogging the tool.

4

GSM/CDMA signal strength

5

GPS signal status

6

Cycles until next service

7

Since manufacturing: operating hours, capacity,

number of cycles

Note: Tool data transmission starts with production of

the tool, independent of registration on i-connect, but

only for the T version of this tool.