EK425LT and EK425LX Battery-powered Crimping Tools

Greenlee / A Textron Company

4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

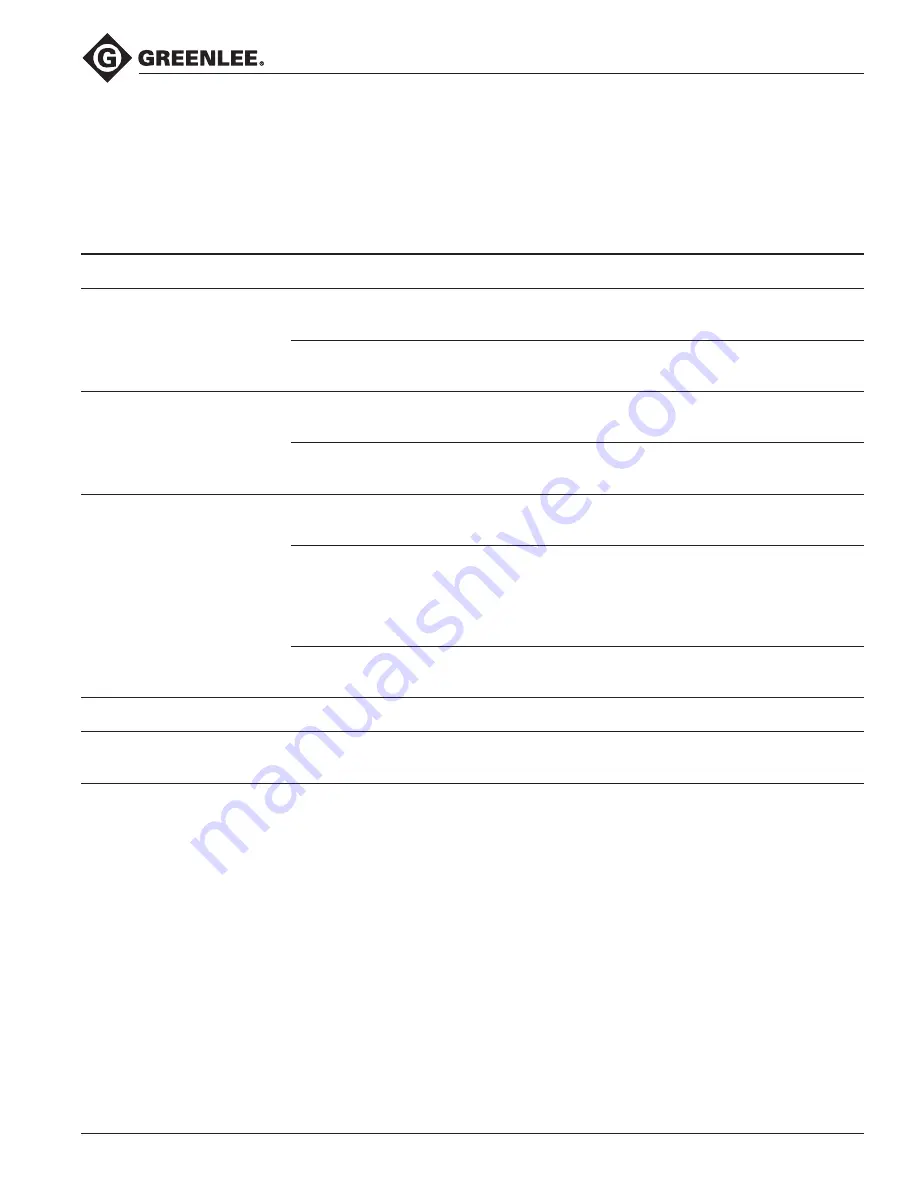

11

Problem

Possible Cause

Probable Remedy

Tool is inoperative.

Dirt, contaminants, etc., in

ram area of tool.

Clean tool.

Tool components worn or

damaged.

Contact Greenlee customer service at

800-435-0786 for warranty service or repair.

Motor is inoperative.

Low or uncharged battery.

Try known charged battery. Inoperative battery may

be discharged or may have reached life expectancy.

Broken switch components.

Contact Greenlee customer service at

800-435-0786 for warranty service or repair.

Motor runs but tool will not

complete a cycle.

Oil level low.

Contact Greenlee customer service at

800-435-0786 for warranty service or repair.

Air in hydraulic system.

Pull trigger and hold retract button simultane-

ously. Run for approximately 10 seconds, and then

attempt to crimp. If unsuccessful, contact Greenlee

customer service at 800-435-0786 for warranty

service or repair.

Cold oil.

Pull trigger and hold retract button simultaneously

to warm oil. Store tool in warm area.

LED glows for 20 seconds.

Battery charge low.

Charge or replace battery.

Tool loses oil.

Damaged internal seal.

Contact Greenlee customer service at

800-435-0786 for warranty service or repair.

Troubleshooting

Before You Begin

1. Make sure that the battery is charged. Recheck

the battery after several minutes to make sure the

battery is holding its charge.

2. Use a

nonflammable

contact cleaner or pencil

eraser to clean the electrical contacts on the battery

and tool.

3. Reinstall the battery and check the tool again.