RK1240 and RK1240C Crimping Tools

Greenlee / A Textron Company

4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

10

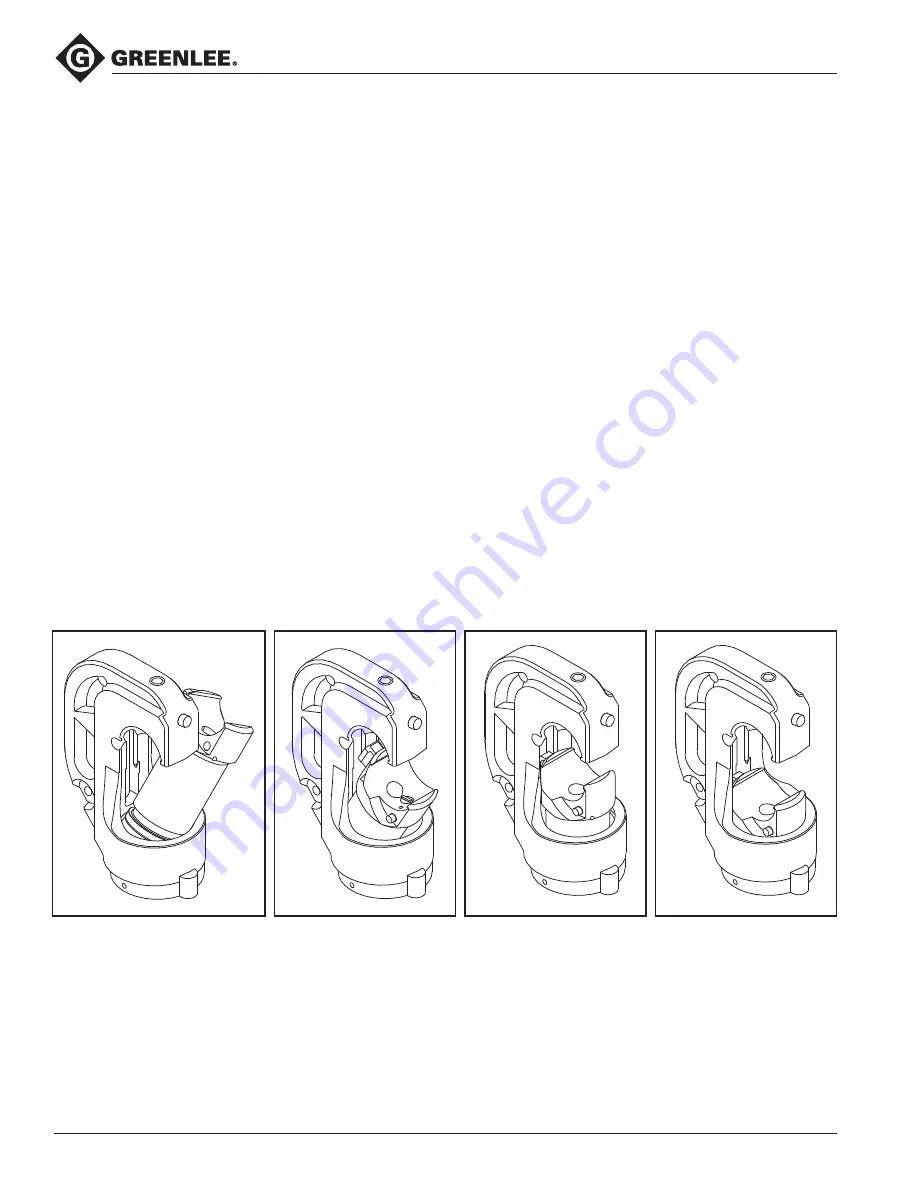

Step 4. Installing the Ram

Assembly

(refer to the Illustration)

1. Lubricate the Die Retainer (4) and Die Release

Button (2) with a Molybdenum Disulfide grease.

Assemble them into the C-head and install Drive

Pin (3). Add two drops of Loctite

®

242

®

Threadlocker

to Screw (6), install Spring (5) from the top of the

C-head and retain with Screw (6). Adjust the Screw

(6) so that the Die Retainer (4) is flush with the head

when the Die Release Button (2) is pressed.

2. Inspect the external surface of the ram and the

inside surface of the cylinder for nicks, gouges or

other imperfections. Replace the ram or cylinder if

necessary.

3. Assemble Spring (11), Die Retaining Pin (10) and Die

Release Button (12) to the Ram (15). Retain with the

Roll Pin (9).

4. Tilt and slide the ram (15) through the opening in

the C-head (1). Align the T-shaped protrusion on the

ram with the T-shaped groove in the C-head and

assemble the ram to the head (see below).

5. Slide the Washer (16) and Wiper (17) onto the

Ram (15) as far as they will go. Place the U-cup Seal

(21) on the Ram.

6. Assemble the Extension Spring (19) to the two

Spring Retainers (18,20).

7. Thread the Spring Retainer (20) into the base of the

Cylinder (23), use a 5mm Allen wrench to tighten the

spring retainer.

8. Lubricate the O-ring (22) and Backup Ring (21) and

threads on the cylinder and C-head.

9. Slide the ram assembly down the C-head and

assemble into the cylinder (23) far enough for full

O-ring and Backup ring engagement.

10. Slip the cylinder into the base of the C-head and

start threading them together. Continue to thread

the cylinder into the C-head until the cylinder con-

tacts the C-head.

11. Lock the C-head in place with the Set Screw (7) .

12. Install Nylon Washer (14) and 8mm Screw (13)

through the ram and tighten securely.

13. Use Pipe Sealer and assemble the 3/8" NPT Pipe

(24) to the 3/8 Coupler (25). Assemble to the

cylinder.