Instruction

Manual

ESSG

page

19

___________________________________________________________________________

3. Warranty

If correct operation is guaranteed and regular service is provided our warranty is 1 year

from the time of delivery. Short circuit damages are excluded. The warranty does also not

cover the cutting blades which are subjected to ware within the determined use.

4. Description of the hydraulic safety cutting unit

4.1. Description of the components

The hydraulic safety cutting unit type ESSG consists of the following components:

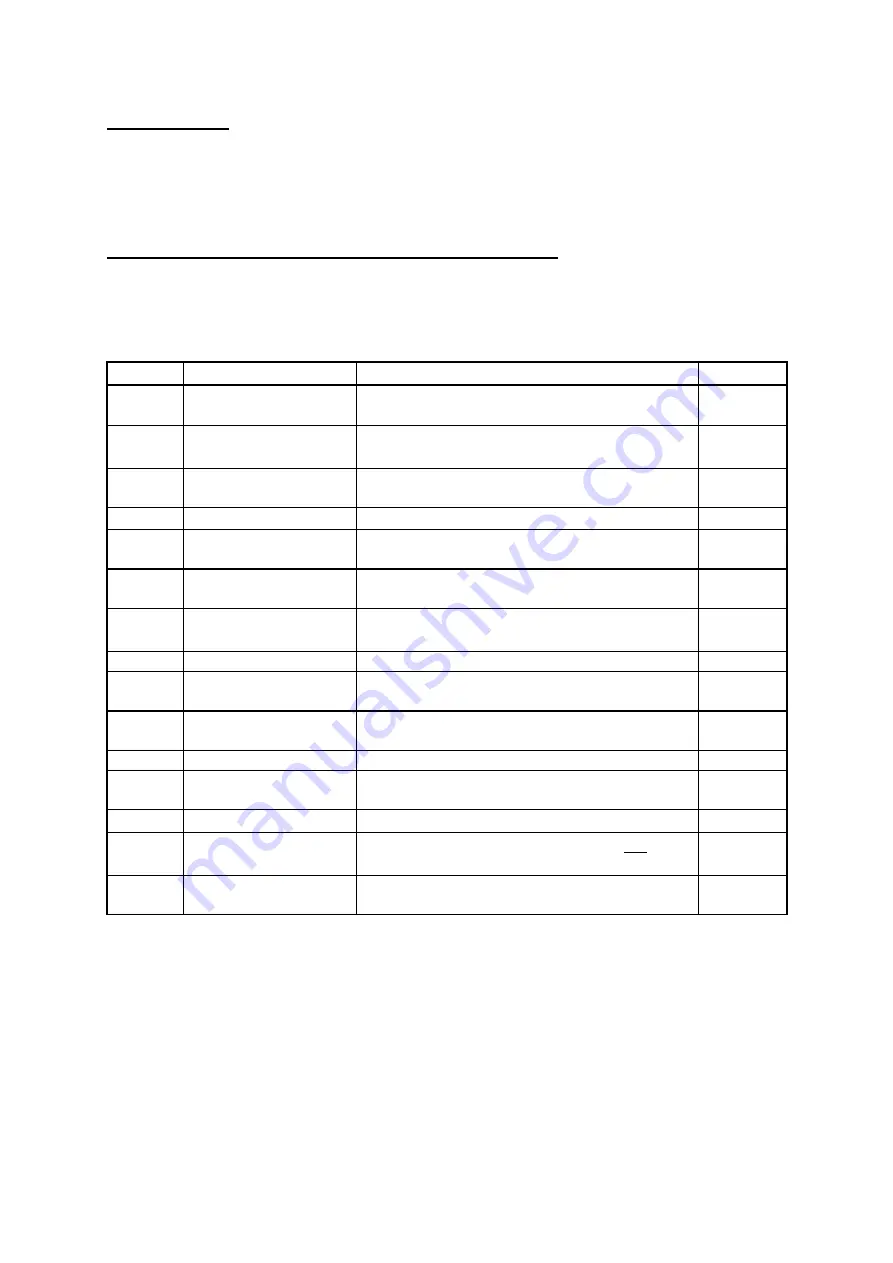

Table 1 (see picture 1)

Pos.-No. Description

Function

See

page

1

Drive unit

Main pump unit with pressure gauge and

grounding connection

2

Light Diode Display

LED

indicator for tool functions (e.g. tool

errors and Service) and battery charge control

3

Connecting device

To connect the high pressure hose to the pump

(consisting of male and female coupling)

4

Trigger

switch to start cutting procedure

5

Transportation lock

Hook to fix the trigger to avoid unintended

operation

6

Release button

To actuate the relief valve to return the oil into

the oil reservoir

7 Key

ring

Loop to secure the tool and/or for assembly

purposes

8

Pressure gauge

Scale indicating the operating pressure of the unit

9

Insulating hose

Non conducting high pressure hydraulic hose

type Europower (CIJN) 852

10

Bending protection

Prevents that the minimum bending radius does

not fall short.

11

Cutting head

Working unit to cut cables and conductors

12

Cutting blades

pivoting (a) and moveable (b) blades to cut not-

reinforced cables and conductors

13 Battery

rechargeable 2,6 Ah NiMH battery (RA4)

14

Removable hand

guard

guard to protect the operating hand, not for

transportation

15

Grounding connection

Hookup for the grounding pillow at the cutting

head and at the drive unit

4.2. Brief description of the important features of the unit

-

The unit is equipped with a special brake which stops the forward motion of the

piston/blade (Pos.-No. 12) when the trigger (Pos.-No. 4) is released.

-

The unit is equipped with a double piston pump which is characterised by a rapid

approach of the blades (Pos.-No. 12) towards the connector and a slow cutting motion.

-

The cutting head (Pos.-Nr. 11) can be smoothly turned by 360° around the longitudinal

axis in order to gain better access to tight corners and other difficult working areas.

-

The ESSG is equipped with a microprocessor which indicated service intervals, internal

checks and low battery charges.

Summary of Contents for Klauke ESSG120/2

Page 42: ......