LYCOMING OPERATOR’S MANUAL

SECTION 5

O-360 AND ASSOCIATED MODELS

MAINTENANCE PROCEDURES

SECTION 5

MAINTENANCE PROCEDURES

The procedures described in this section are provided to guide and instruct personnel in performing such

maintenance operations that may be required in conjunction with the periodic inspections listed in the

preceding section. No attempt is made to include repair and replacement operations that will be found in the

applicable Lycoming Overhaul Manual.

1. IGNITION AND ELECTRICAL SYSTEM.

a. Ignition Harness and Wire Replacement –

In the event that an ignition harness or an individual lead is

to be replaced, consult the wiring diagram to be sure harness is correctly installed. Marklocation of

clamps and clips to be certain the replacement is clamped at correct locations.

b. Timing Magnetos to Engine.

(1) Remove a sparkplug from No. 1 cylinder and place a thumb over the sparkplug hole. Rotate the

crankshaft in direction of normal rotation until the compression stroke is reached, this is indicated

by a positive pressure inside the cylinder tending to push the thumb off the spark plug hole.

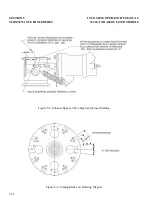

Continue rotating the crankshaft until the advance timing markon the front face of the starter ring

gear is in alignment with the sm

all hole located at the two ocloc

kposition on the front face of

the starter housing. (Ring gear may be marked at 20°and 25°. Consult specifications for correct

timing markof your installation.) At this point, the engine is ready for assembly of the magnetos.

(2)

Single Magneto –

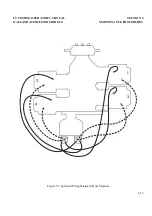

Remove the inspection plugs from both magnetos and turn the drive shaft in

direction of normal rotation until (-20 and -200 series) the first painted chamfered tooth on the

distributor gear is aligned in the center of the inspection window;(-1200 series) the applicable

timing mark on the distributor gear is approximately aligned with the mark on the distributor

block. See Figure 5-2. Being sure the gear does not move from this position, install gaskets and

magnetos on the engine. Note that an adapter is used with impulse coupling magneto. Secure

with (clamps on -1200 series) washers and nuts;tighten only finger tight.

(3) Using a battery powered timing light, attach the positive lead to a suitable terminal connected to

the switch terminal of the magneto and the negative lead to any unpainted portion of the engine.

Rotate the magneto in its mounting flange to a point where the light comes on, then slowly turn it

in the opposite direction until the light goes out. Bring the magneto backslowly until the light

just comes on. Repeat this with the second magneto.

(4) Back off the crankshaft a few degrees, the timing lights should go out. Bring the crankshaft

slowly back in direction of normal rotation until the timing mark and the hole in the starter

housing are in alignment. At this point, both lights should go on simultaneously. Tighten nuts to

specified torque.

(5)

Dual Magnetos –

Remove the timing window plug from the most convenient side of the housing

and the plug from the rotor viewing location in the center of the housing.

(6) Turn the rotating magnet drive shaft in direction of normal rotation until the painted tooth of the

distributor gear is center in the timing hole. Observe that at this time the built in pointer just

ahead of the rotor viewing window aligns with either the L or R (depending on rotation).

5-1