LYCOMING OPERATOR’S MANUAL

SECTION 5

O-360 AND ASSOCIATED MODELS

MAINTENANCE PROCEDURES

CAUTION

NEVER USE A MAGNET TO REMOVE HYDRAULIC PLUNGER ASSEMBLIES FROM

THE CRANKCASE. THIS CAN CAUSE THE CHECK BALL TO REMAIN OFF ITS SEAT,

RENDERING THE UNIT INOPERATIVE.

d. Assembly of Hydraulic Tappet Plunger Assemblies –

To assemble the unit, unseat the ball by inserting

a thin clean wire through the oil inlet hole. With the ball off its seat, insert the plunger and twist

clockwise so that the spring catches. All oil must be removed before the plunger is inserted.

e. Assembly of Cylinder and Related Parts –

Rotate the crankshaft so that the connecting rod of the

cylinder being assembled is at the top center of compression stroke. This can be checked by placing

two fingers on the intake and exhaust tappet bodies. Rockcrankshaft backand forth over top center. If

the tappet bodies do not move the crankshaft is on the compression stroke.

(1) Place each plunger assembly in its respective tappet body and assemble the socket on top of

plunger assembly.

(2) Assemble piston with rings so that the number stamped on the piston pin boss is toward the front

of the engine. The piston pin should be a handpush fit. If difficulty is experienced in inserting the

piston pin, it is probably caused by carbon or burrs in the piston pin hole. During assembly,

always use a generous quantity of oil, both in the piston hole and on the piston pin.

(3) Assemble one piston pin plug at each end of the piston pin and place a new rubber oil seal ring

around the cylinder skirt. Coat piston and rings and the inside of the cylinder generously with oil.

(4) Using a piston ring compressor, assemble the cylinder over the piston so that the intake port is at

the bottom of the engine. Push the cylinder all the way on, catching the ring compressor as it is

pushed off.

NOTE

Before installing cylinder hold-down nuts, lubricate crankcase thru-stud threads with any

one of the following lubricants, or combination of lubricants

1. 90% SAE 50W engine oil and 10% STP.

2. Parker Thread Lube.

3. 60% SAE 30 engine oil and 40% Parker Thread Lube.

(5) Assemble hold-down plates (where applicable) and cylinder base hold-down nuts and tighten as

directed in the following steps.

NOTE

At any time a cylinder is replaced, it is necessary to retorque the thru-studs on the cylinder

on the opposite side of the engine.

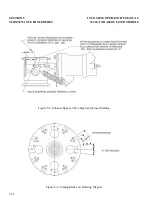

(a)

(Engines using hold-down plates) –

Install shims between cylinder base hold-down plates and

cylinder barrel, as directed in Figure 5-3, and tighten ½ inch hold-down nuts to 300 in.-lbs.

(25 ft.-lbs.) torque, using the sequence shown in Figure 5-3.

5-7