www.tuffstuffitness.com

CG-9506 Bicep/Tricep

21

Parts List

REV0

Item

No.

Description

Rev. Part

No. Qty. Item

No.

Description

Rev.

Part

No.

Qty.

1

ADJ

PULLEY

BRACKET

(3

1/2

PULLEY)

0

UP8800

1

36

BNH3395

1

2

BASE

FRAME

0

UP8801

1

37

BNH0065

4

3

CABLE

0

UP8802

1

38

BNH2520

2

4

CABLE

RETAINER

BRACKET

3

1/2

PULLEY

0

UP0998

4

39

BNH0572

3

5

FRONT

UPRIGHT

0

UP8803

1

40

BNH1214

2

6

GUIDE

ROD

3/4

RD

X

50

3/8

0

UP8461

2

41

BNH3089

4

7

SELECTOR

PIN

W/COIL

3/8

X

4

GOLD

KNOB

0

UP3035

1

42

BNH1628

1

8

WEIGHT

SHIELD

FRONT

0

UP8876

1

43

BNH0229

1

9

WEIGHT

SHIELD

REAR

0

UP8877

1

44

BNH3351

1

10

WEIGHT

STACK

FRAME

0

UP8804

1

45

BNH3662

1

11

BNH4345 19

46

BNH2041

1

12

BNH2020 1

47

BNH2044

4

13

BNH4331 2

48

BNH3704

1

14

BNH0553 6

49

BNH3691

1

15

BNH4230 2

50

BNH2983

1

16

BNH1724 1

51

BNH0704

2

17

BNH3323 4

52

BNH2926

1

18

BNH0206 2

53

BNH3708

1

19

BNH3398 1

54

BNH3134

1

20

BNH3705 1

55

BNH3138

1

21

BNH1717 2

56

BNH2967

1

22

BNH2031 2

57

BNH2908

1

23

BNH2030 27

58

BNH3172

1

24

BNH2167 2

59

BNH3145

2

25

BNH2038 2

60

BNH3088

1

26

BNH2040 4

61

BNH3192

1

27

BNH2046 6

62

BNH3181

1

28

BNH1771 1

63

BNH3113

1

29

BNH2026 15

64

BNH2925

1

30

BNH0506 5

65

BNH3137

1

31

BNH4329 2

66

BNH4069

1

32

BNH3393 1

67

BNH3135

1

33

BNH3686 1

68

BNH3699

1

34

BNH0068 4

69

BNH3147

2

35

BNH3394 1

Item

No.

Description

Rev. Part

No. Qty. Item

No.

Description

Rev.

Part

No.

Qty.

*1

ADJ

PULLEY

BRACKET

(3

1/2

PULLEY)

0 UP8800X1 1

*8

WEIGHT

SHIELD

FRONT

0

UP8468X1

1

*2

BASE

FRAME

0 UP8801X1 1

*10

WEIGHT

STACK

FRAME

0

UP8804X1

1

*5

FRONT

UPRIGHT

0 UP8803X1 1

*32

BNH3393X1

1

FLAT

WASHER

SAE

Z/P

3/8

ʺ

HEX

HEAD

CAP

SCREW

GR

‐

5

Z/P

1/2

‐

13

X

1

1/4

ELLIPTICAL

RUBBER

SHOE

FINISHED

HEX

NUT

Z/P

1/2

‐

13

FLANGED

SPACER

Z/P

3/8

X

30MM

FLAT

HEAD

SOCKET

CAP

SCREW

Z/P

M6

‐

1.0

X

50

FLAT

WASHER

3/8

ID

X

1

1/2

OD

X

3/16

THICK

7/8

RD

X

2

15/32

LINK

3/16

CABLE

BLACK

NYLON

PULLEY

3/8

X

1

X

3

1/2

(P

‐

35375

‐

H)

CABLE

STOPPER

SHELL

1

1/2

X

1

3/4

EDGE

PROTECTOR

CHROME

11

GA

FLAT

WASHER

SAE

Z/P

1/2

ʺ

CG-9506

Parts List

RUBBER

CORR

MAT

ON

LOW

ROW

BAR

REST

RUBBER

DONUT

3/4

X

2

1/2

SHROUD

LID

RUBBER

MAT

LARGE

TRICEPS

ʺ

PRESS

DOWN

ʺ

ROPE,

DOUBLE

‐

GRIP

(#MTR)

URETHANE

BUMPER

1

3/4

U

‐

STYLE

TAPPED

HOLE

NUT

M6

LEVELER

HEX

HEAD

CAP

SCREW

GR

‐

5

Z/P

3/8

‐

16

X

2

HEX

HEAD

CAP

SCREW

GR

‐

5

Z/P

3/8

‐

16

X

2

1/2

LABEL

WARNING

KEEP

BODY,

HANDS,

1

1/2

X

2

1/4

LABEL

‐

CG

‐

9500

SERIES

PANTONE

ON

CHROME

BASE

1.375

X

12.75

LABEL

‐

DANGER

DO

NOT

LEAN

AGAINST,

1.75X2.375

HEX

HEAD

CAP

SCREW

GR

‐

5

Z/P

3/8

‐

16

X

1

1/4

10

LB

TOP

PLATE

W/22

ʺ

SLTR

BAR

19

BLK

WTS

ASM

PLASTIC

SHROUD

LID

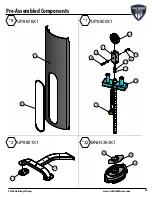

PRE ASSEMBLED COMPONENTS

SHROUD

LID

RUBBER

MAT

SMALL

SNAP

LINK

Z/P

8MM

X

80MM

SUPER

LUBE

TEFLON

LUBRICANT

82340

COIL

CHAIN

Z/P

3/16

X

8

HEX

KEY

ALLOY

4

MM

OVAL

HEAD

PHILLIPS

MACHINE

SCREW

Z/P

#10

‐

24

X

1

1/8

PLASTIC

SHROUD

LID

HEX

HEAD

CAP

SCREW

GR

‐

5

Z/P

3/8

‐

16

X

1

3/4

HEX

HEAD

CAP

SCREW

GR

‐

5

Z/P

3/8

‐

16

X

3

LOW

ROW

BAR

1

1/4

ALUMINUM

NYLON

INSERT

THIN

PATTERN

LOCK

NUT

Z/P

3/8

‐

16

NYLON

PULLEY

3/8

X

1

X

4

1/2

BLACK

10

LB

STEEL

WEIGHT

PLATE

BLACK

4

X

10

(EA)

SPLIT

LOCK

WASHER

Z/P

3/8

ʺ

SPLIT

LOCK

WASHER

Z/P

1/2

ʺ

LABEL

‐

WARNING

KEEP

BODY,

HANDS...

1X2

‐

5/8

LABEL

‐

WARNING

ANCHOR

BOLT,

2

X

1

1/4

ʺ

LABEL

‐

TFI

4

HIGH

X

4.23

WIDE

BLUE

AND

CHROME

LABEL

‐

DANGER

USE

THIS

EQUIP.

ONLY

(COMM.

LINE)

1.5

X

2.375

UHMW

STOPPER

20

OD

MM

X

10.5

ID

MM

X

25.4

MM

FACILITY

SIGN

BE

ALERT!

THE

FITNESS

EQUIPMENT

LABEL

‐

CAUTION

ADJUST

LEVELER

LABEL

‐

IMPORTANT

CHECK

CABLES

LABEL

‐

IMPORTANT

FOR

SMOOTH

PERFORMANCE...

1.5

X

1.250

LABEL

‐

INSPECTIONS

RECOMMENDED

INSPECTION…

LABEL

‐

NUMBERS

10

‐

200

LBS/KGS

7/8

X

3

YELLOW

&

BLACK

LABEL

‐

SCHEDULE

REPLACEMENT

PARTS…

HEX

HEAD

CAP

SCREW

GR

‐

5

Z/P

1/4

‐

20

X

1

3/4

NYLON

INSERT

LOCK

NUT

Z/P

1/4

‐

20

LABEL

‐

TFI

SERIAL

NO.

2.5

X

1.5

LABEL

‐

COMMERCIAL

WARRANTY

LABEL

‐

WARNING_SERIOUS

INJURY

OR

DEATH

LABEL

‐

EXERCISE

CHART

COLOR CHART

GRAY= SUB-ASSEMBLY PARTS

BLACK= HARDWARE

Summary of Contents for CG-9506

Page 24: ......