©Copyright Task Force Tips LLC 2014-2021

4

LIA-208 May 19, 2021 Rev05

1.0 MEANING OF SAFETY SIGNAL WORDS

A safety related message is identified by a safety alert symbol and a signal word to indicate the level of risk involved with a particular

hazard. Per ANSI Z535.6, the definitions of the four signal words are as follows:

2.0 SAFETY

3.0 GENERAL INFORMATION

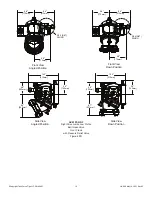

The Low Profile Jumbo Ball Intake Valve is intended for use on either the intake manifold of a fire engine or on a discharge port of a fire

main. The valve is available in several versions to minimize interference with surrounding components. An adjustable pressure relief

valve mounted on the valve opens to relieve any excess pressure that may damage the hose or the pump. The valve may be used for

pressure or vacuum/drafting service.

An electric remote controlled (RC) model allows the valve to be operated from a remote location. A typical installation consists of the RC

valve and a remote display operator station. Motor controls are designed to auto sense 12 VDC or 24 VDC operation. The motor control

circuit utilizes a position encoder and current limiting to protect the drive train at the ends of travel. Unit is supplied with 2’ of cable with a

plug on RC valve and 15’ of cable with a receptacle to minimize installation effort. Cable has only four conductors (two for power and two

for communications) further easing installation effort. To complete the installation, the installer will need to mount and wire the remote

display operator station. The display has 20’ of cable. The power supply for the RC valve will need to be connected to a protected circuit

from the truck's power distribution center.

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result in death or serious

injury.

CAUTION

CAUTION indicates a potentially hazardous situation which, if not avoided, could result in minor

or moderate injury.

NOTICE

NOTICE is used to address practices not related to physical injury.

DANGER

An inadequate supply of pressure and/or flow will cause an ineffective stream and can result

in injury or death. Choose operating conditions to deliver adequate fire suppression.

WARNING

This equipment is intended for use by trained personnel for firefighting. Use of this equipment for

other purposes may involve hazards not addressed by this manual. Seek appropriate guidance and

training to reduce risk of injury.

WARNING

Equipment may be damaged if frozen while containing significant amounts of water. Such damage

may be difficult to detect visually. Subsequent pressurization can lead to injury or death. Any time

the equipment is subject to possible damage due to freezing, it must be tested and approved for

use by qualified personnel before being considered safe for use.

WARNING

Sudden changes in valve position can cause pressure spikes (water hammer) and could lead to

hose or pipe failure or an out of control monitor. Open and close the valve slowly to avoid water

hammer.

WARNING

Interrupting flow to the device could cause injury or death. Avoid situations that may interrupt

flow to the device such as: hose line kinks, traffic running over hose, and automatic doors or

devices that can pinch the hose.

CAUTION

The electric drives are current limited but may still produce enough force to cause injury. To avoid

injury from a moving monitor:

• Be aware that the monitor may be remotely operated

• Keep hands and fingers away from pinch points on the monitor

• Never operate the manual override while electric controls are in operation

NOTICE

This equipment has current limiting capability which stops the motor if an obstruction is

encountered. Equipment must be installed as instructed using the correct controls and electrical

boxes. Failure to do so will result in damage to the electric motor and loss of current limiting

controls.

NOTICE

To prevent mechanical damage, do not drop or throw equipment.