R

epair

P 2 / 7

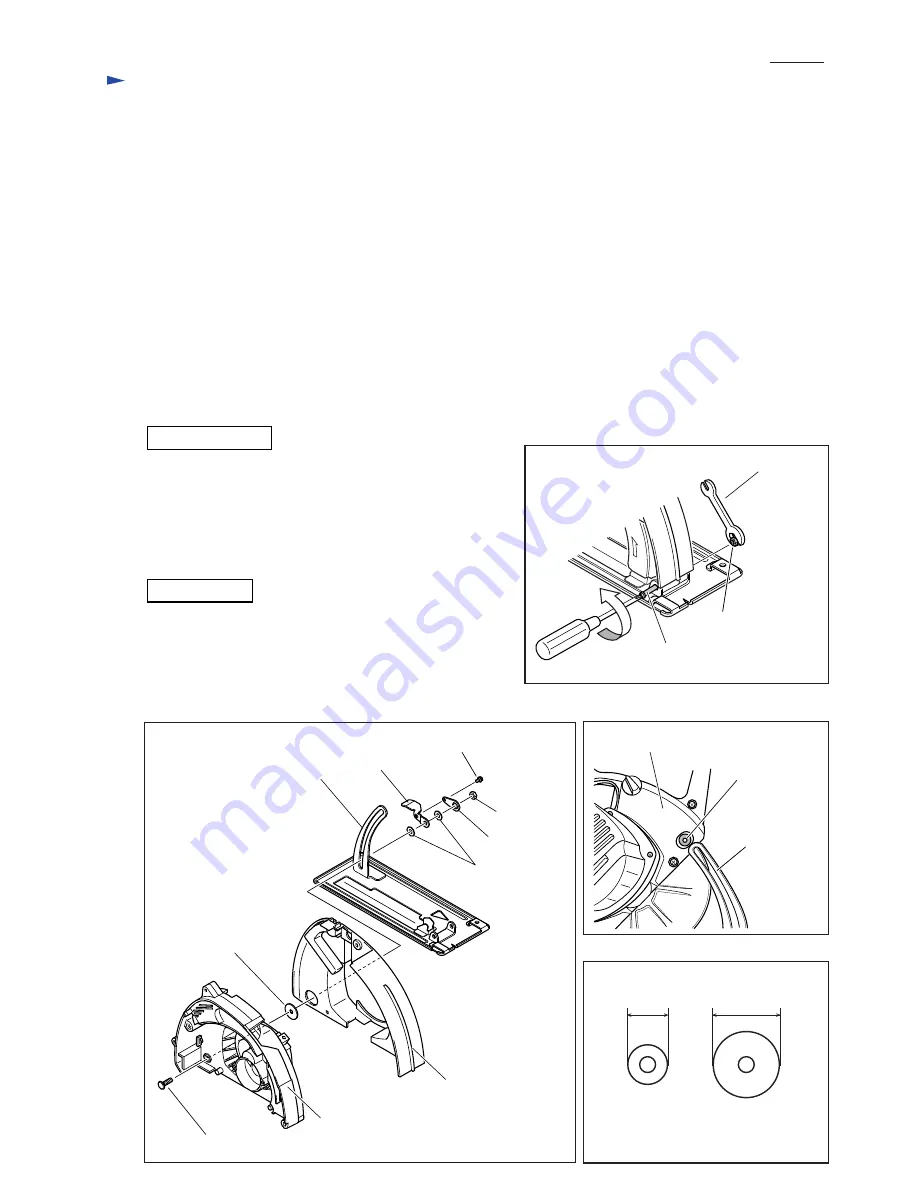

Fig. 1

Fig. 2

Fig. 3

Fig. 4

Wrench 8

[2] LUBRICATION

[1] NECESSARY REPAIRING TOOLS

Retaining ring pliers ST-2N (1R003) .................... For removal/installation of Safety cover

Bearing setting pipe 16-8.2 (1R026) ..................... For removing Gear

Ring 22 (1R217) .................................................... For removing Gear

Bearing extractor (1R263) ..................................... For removing Bearing box

Bearing extractor (1R269) ..................................... For removing Ball bearing

Retaining ring S and R pliers (1R291) ................... For removal/installation of the Retaining ring on Spindle

Wrench for bearing retainer (1R316) ..................... For removal/installation of Bearing retainer

Put 8g of Makita grease N No.1 in the gear room of Gear housing complete.

[3] DUSASSEMBLING AND ASSEMBLING

CAUTION: Be sure that the tool is switched off and unplugged before starting disassembling/assembling.

CAUTION: When using a blower for cleaning, always wear safety goggle to protect your eyes from metal dust.

[3] -1. Replacement of Base

DISASSEMBLING

1) Remove (+) Pan head screw M5 from the hinge portion of

Base while holding Hex lock nut M5-8 with wrench 8 or the

like so that it cannot turn together with the screw. (

Fig. 1

)

2) Release depth adjustment lock, and then remove Pan head

screw M4x8. Now Lock plate can be removed from the depth

guide of Base. Remove Hex nut M6, and now Lock lever

section can be disassembled as illustrated in

Fig. 2

.

Always follow the instructions of the SAFETY RULES and OPERATING INSTRUCTIONS described in the

instruction manual.

(+) Pan head screw M5

Hex lock nut M5-8

Lever plate

Gear housing (blade case)

Flat washer 6

(253804-1)

Lock plate

Hex nut M6

Pan head screw M4x8

Flat washer 6

(253783-3)

Depth guide

Cap square neck bolt M6x20

ASSEMBLING

Do not forget to put Flat washer 6 (Part No.253783-3) between

Gear housing (blade case) and the depth guide of Base. (

Fig. 3

)

Be careful not to place Flat washer 6 (Part No.253804-1) there.

The two Flat washers can be easily distinguished by outer

diameter as illustrated in

Fig. 4

.

Flat washer 6

(253783-3)

Depth guide

Gear housing cover

Gear housing cover

Flat washer 6

(253804-1)

15mm

Flat washer 6

(253783-3)

25mm