Maintenance

1)

Empty the spreader after each use. Return the

unused material to its original container and seal to

prevent moisture-caused clumping.

2)

Wash the spreader thoroughly. Let spreader dry in

a sunny or heated area. Wipe or blow off excess

water to prevent corrosion. Clean all residue from the

rotor plate.

3)

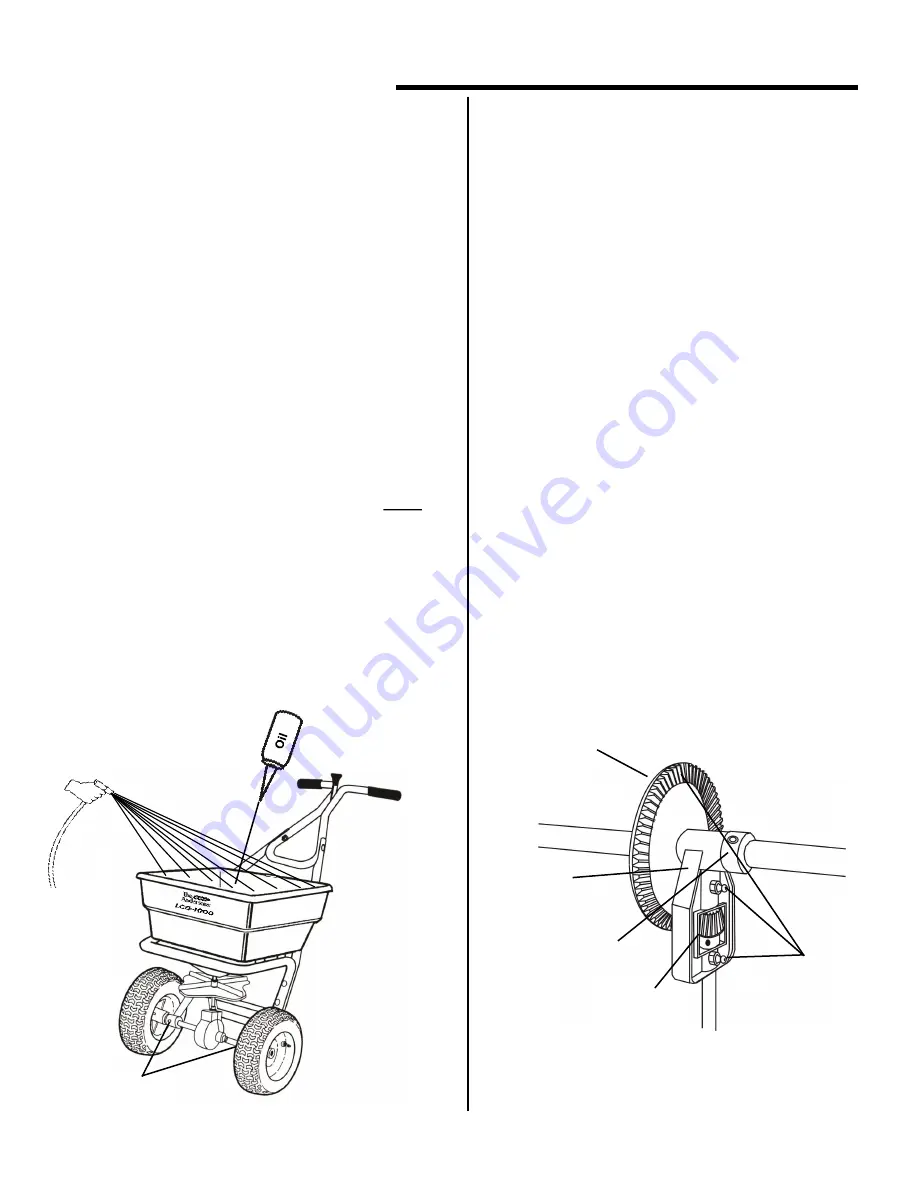

Periodically grease the axle bearing housings and

apply a few drops of oil to the impeller shaft bearing

as shown below.

4)

Periodically oil the pivot points on all control

linkage and the spring inside the rate control housing.

5)

Periodically clean and inspect the gears by

removing the gearbox cover halves. Apply a small

amount of grease to fittings on the gear carrier and

the gear teeth for lubrication. Be sure to reinstall the

gearbox cover halves prior to use.

4

6)

Gear mesh should be checked on a regular

basis during high use periods. Clearance between

the axle gear and pinion gear should be minimal

but not tight. If adjustment is necessary, loosen

axle collar set screw and hold gears together. Slide

axle collar against the gear support and tighten

axle collar set screw. Spin drive wheel. Gears

should run freely and smoothly.

7)

Maintain tire pressure at

20 psi maximum

.

8)

If the axle requires disassembly, be sure to

reassemble it so the drive wheel attaches on the

right side as you push the spreader. Incorrect

spread pattern will result if the rotor plate does not

rotate in a counter-clockwise direction.

Axle Collar

Grease

Pinion Gear

Axle Gear

Oil Impeller Shaft

Bearing in Hopper

Grease Axle

Bearings

Gear Support