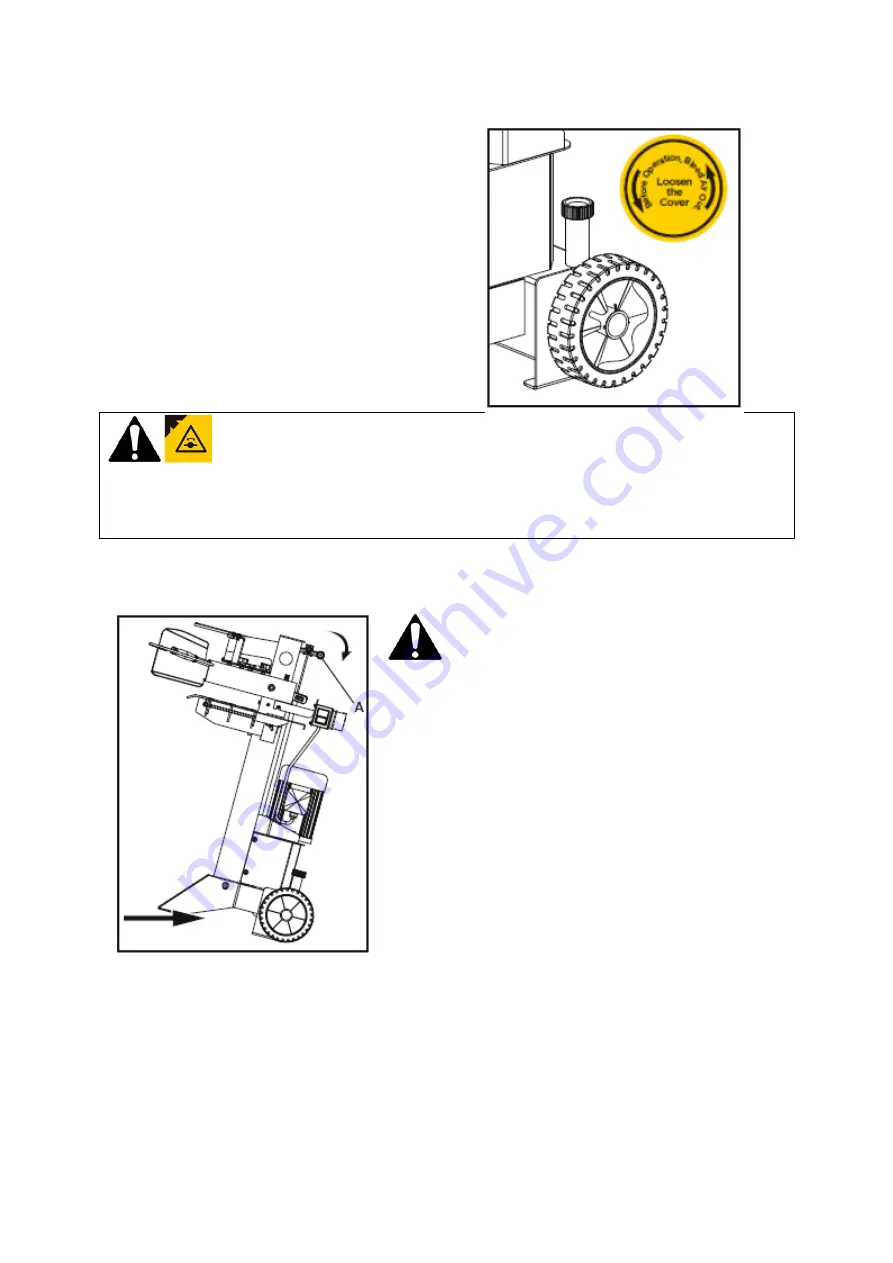

BLEED SCREW

IMPORTANT

Before operating the logsplitter, the Oil Filler/Air

Bleed should be loosened a few rotations until air

can go in and out of the oil tank smoothly. Air flow

through the Oil Filler/Air Bleed hole should be

noticeable while the logsplitter is working. Before

moving the log splitter, ensure the Oil Filler/Air

Bleed is tightened to avoid oil leaks

.

FAILURE TO LOOSEN THE OIL FILLER/AIR BLEED WILL KEEP SEALED AIR IN THE HYDRAULIC SYSTEM

COMPRESSED. SUCH CONTINUOUS AIR COMPRESSION WILL BLOW OUT THE SEALS OF THE HYDRAULIC

SYSTEM AND CAN CAUSE PERMANENT DAMAGE TO THE LOGSPLITTER, WHICH IS NOT COVERED UNDER THE

TERMS & CONDITIONS OF THE MANUFACTURERS WARRANTY.

TRANSPORTING YOUR LOGSPLITTER

The logsplitter is equipped with 2 wheels for minor moving. To move the log splitter to the work site. Grip the

handle to tilt the log splitter slightly after making sure the oil tank cover is tightened.

DO NOT TRANSPORT THE LOGSPLITTER WITH WOOD LOADED

Summary of Contents for 1938182001

Page 19: ...WIRING HYDRAULIC SYSTEM DIAGRAMS WIRING DIAGRAM HYDRAULIC DIAGRAM ...

Page 21: ...PARTS DIAGRAM THLSV7 1938182001 ...

Page 27: ......