OPERATION

APPLICATION CONDITIONS

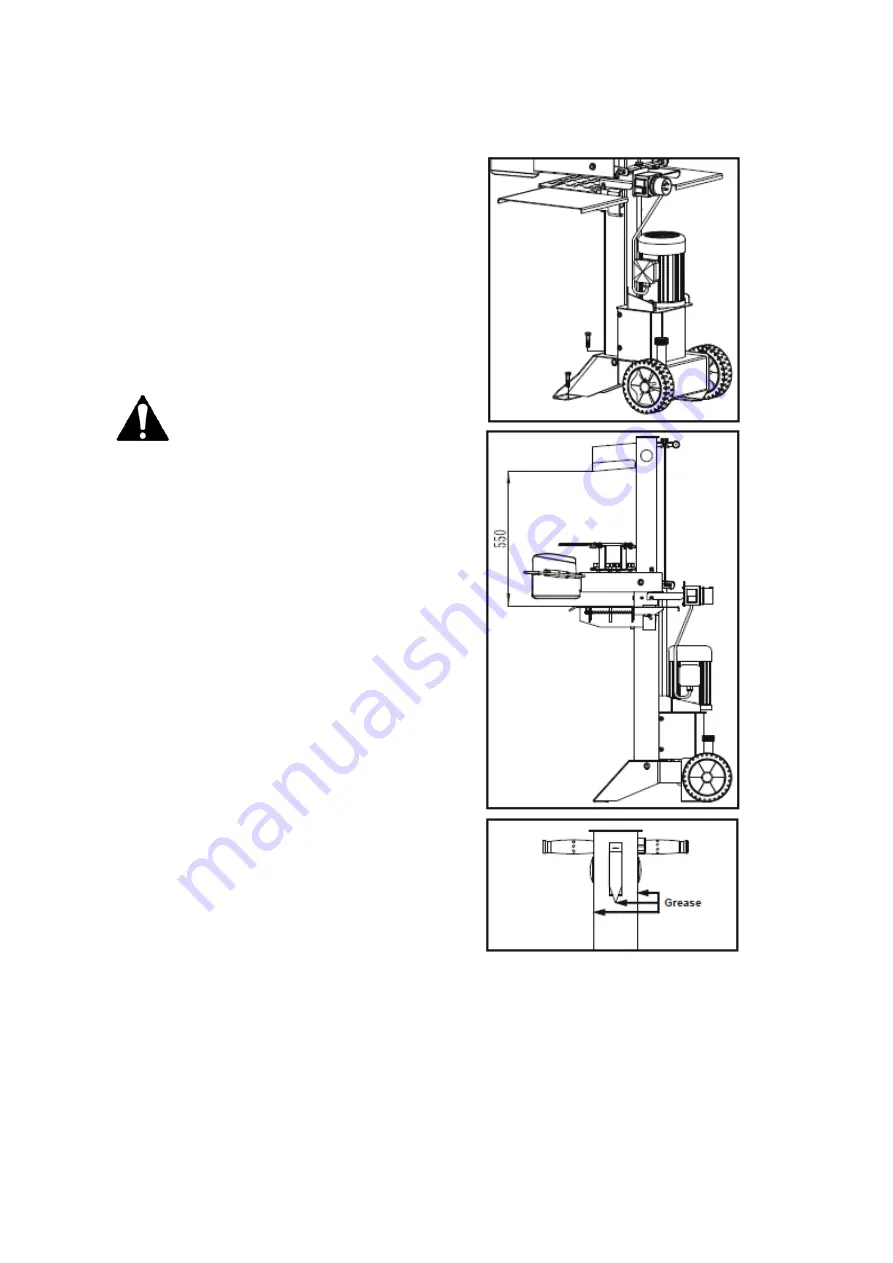

Before operation, we recommend the machine is

fixed to the machine using Bolts M10x30 (not

supplied) on level ground.

1.

Plan your work site. Work safely and save effort

by planning your work beforehand. Have your

logs positioned where they can be easily

reached. Have a site located to stack the split

wood or load it onto a nearby truck or another

carrier.

2.

Prepare the logs for splitting. This splitter

accommodates logs up to 105cm in length.

When cutting up limbs and large sections, do

not cut sections any longer than 105cm.

Do not attempt to split green logs. Dry, seasoned

logs split much more easily, and will not jam as

frequently as green wood.

•

To apply a thin coat of grease to the surfaces of

the ram before operation will lengthen the

durability of the ram.

•

Route the power cord. Route the cord from the

power source to the splitter in a way that

safeguards against tripping on the cord, or the

cord becoming damaged during the work

session. Protect the power cord from impacts,

pulling or corrosive materials.

•

Open the Oil Filler/Air Bleed. Loosen the oil tank

cover a few turns whenever the splitter being

used. Retighten this cover when you finished.

•

While operating under extremely low

temperature, keep the log splitter running

under no load for 15 minutes to preheat the

hydraulic oil.

•

Before initial operation, check to be sure the

two-handed operation is properly functioning

by following steps:

❖

Lower both control levers, splitting wedge

lowers to approx. 5cm above the take

above the highest table position.

❖

Release either of the levers, splitting wedge

should remain in the original position.

❖

Release both levers, the ram should rise to

the highest position automatically.

Summary of Contents for 1938182001

Page 19: ...WIRING HYDRAULIC SYSTEM DIAGRAMS WIRING DIAGRAM HYDRAULIC DIAGRAM ...

Page 21: ...PARTS DIAGRAM THLSV7 1938182001 ...

Page 27: ......