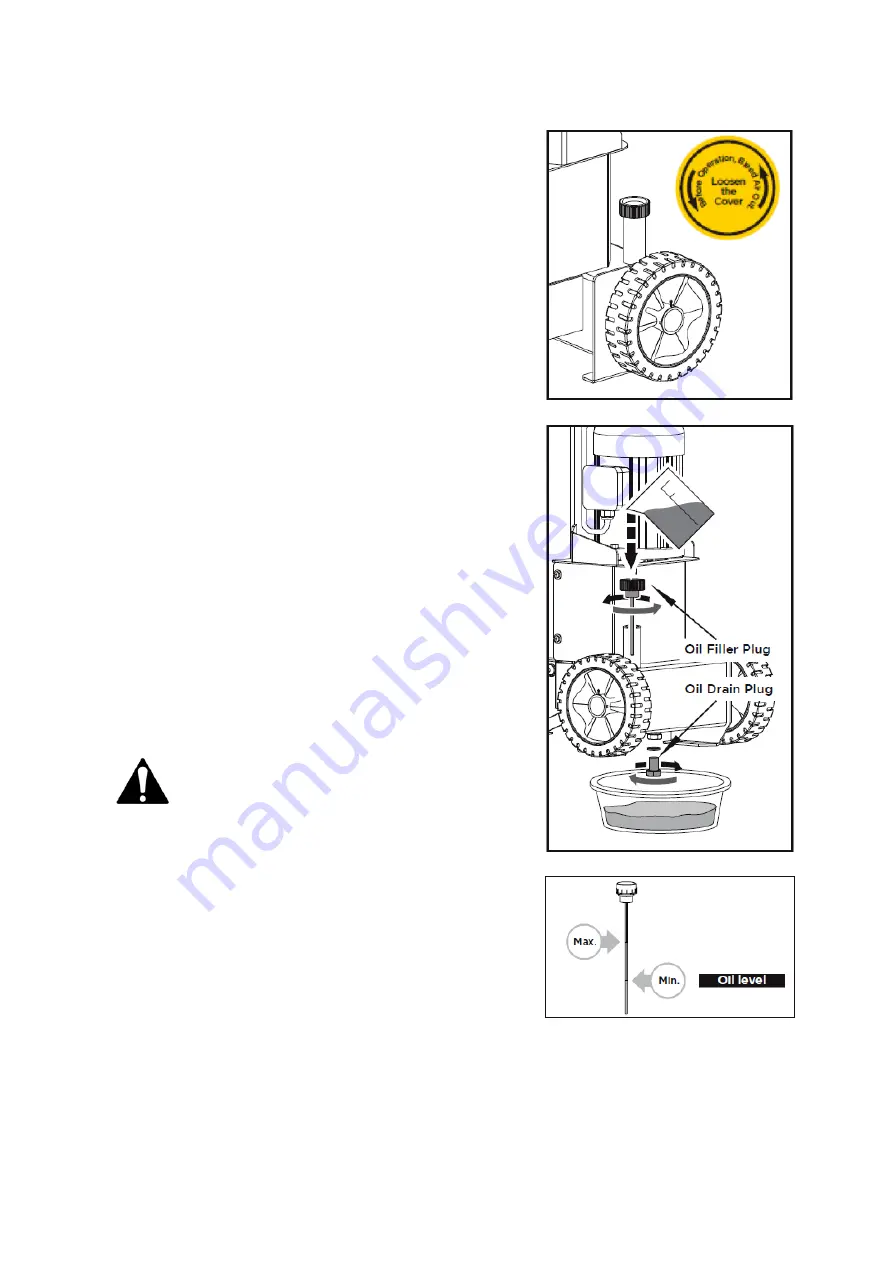

REPLACING HYDRAULIC OIL

The hydraulic system is a closed system with oil tank, oil pump and

control valve. Check oil level regularly with dipstick. Low oil levels

can damage the oil pump. Oil Level should measure approx. 1 ~ 2

cm lower than the upper surface of the oil tank.

The oil should be completely changed once a year.

•

Make sure moving parts stops and the log splitter is unplugged

from the power source.

•

Make sure that no dirt or debris finds its way into the oil tank

•

Use a drain pan to aid in the removal of all used oil and

particles.

•

Remove oil drain plug to drain oil from the hydraulic

transmission system. Examine oil for metal chips as a

precaution to future problems.

•

Following an oil change, activate the log splitter a few times

without actually splitting with the Oil Filler/Air Bleed removed,

to disperse any trapped air in the hydraulic system.

The following hydraulic oils or equivalent Type 22 are

recommended for the log splitter’s hydraulic transmission

system:

o

HANDY PARTS Logsplitter Oil WPL110 (1L), WPL113 (5L)

o

SHELL Tellus 22

o

MOBIL DTE 11

o

ARAL Vitam GF 22

o

BP Energol HLP-HM 22

•

Clean the Dipstick and put it back into the oil tank.

•

Never exceed the maximum level. Empty oil if the maximum

level is exceeded until the oil level is between the minimum &

maximum marks on the dipstick.

•

The machine will operate as designed with oil in between the

minimum & maximum marks.

•

Clean the dipstick before replacing it. Make sure it is

tightened to avoid leaks during transit.

Read dipstick to determine SHARPENING WEDGE the maximum

and minimum of the oil level. Low oil can damage the oil pump.

Overfilling can result in excessive temperature in the hydraulic

transmission system.

Summary of Contents for 1938182001

Page 19: ...WIRING HYDRAULIC SYSTEM DIAGRAMS WIRING DIAGRAM HYDRAULIC DIAGRAM ...

Page 21: ...PARTS DIAGRAM THLSV7 1938182001 ...

Page 27: ......