OPERATING INSTRUCTIONS

WARNING

Before using the Trailer, review the below instructions & safety information within the manual.

Failure to follow these instructions may result in property damage or injury to the operator or

bystanders.

1.

DO NOT

at any time carry passengers.

2.

DO NOT

exceed the rated capacity of 650lb (295kg).

3.

ALWAYS

secure and lock the Trailer to the vehicle hitch before operating.

4.

ONLY

use approved vehicles when towing the Trailer (Lawn/Garden Tractors and ATVs)

5.

NEVER

tow the Trailer with the box raised.

6.

DO NOT

over fill the Trailer. This could cause the Trailer and towing vehicle to lose traction

and skid out of control.

7.

ONLY

fill the Trailer to a manageable dumping load. Extremely heavy loads will be difficult to

operate the tipping mechanism.

8.

ONLY

use the Trailer for its intended purpose.

9.

ALWAYS

make sure that the combined weight of the tow vehicle and the operator is greater

than the load of the Trailer. If the Trailer is heavier it may be difficult to control.

10.

DO NOT

use the Trailer on public roads.

11.

NEVER

exceed 10mph when towing the Trailer.

12.

DO NOT

make sharp turns as this may cause the Lawn/Garden Tractor or ATV tyres to rub against

the Towed Trailer.

13.

ALWAYS

slow down before turning.

14.

ALWAYS

use caution when reversing the Trailer. To avoid the Trailer

“jack

-

knifing” always

reverse in a straight line.

CAUTION

To avoid possible injury, be sure that no bystander is near the cart before releasing the latch.

TOW CART

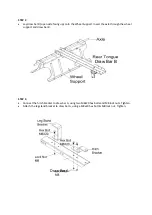

To convert the cart for towing, remove the plastic cap from the draw bar. Remove the Ø13x98

clevis pin and R Pin which secure draw bar A in the storage position underneath draw bar B. Pivot

draw bar A outward and secure it in the towing position using the same clevis pin and hairpin

cotter. Push the handle in all the way against the front of the tray depressing the buttons in the

bottom of the handle.

Always test to make sure your tractor has adequate towing and braking capabilities whenever

hauling a substantial amount of weight in your cart. Use extra caution when operating on slopes.

Do Not Exceed the 650 LB. (295kg) weight capacity of the cart.

CAUTION

Vehicle braking & stability may be affected by the cart. Be aware of changing conditions on slopes

Distribute the weight of the load evenly in the cart to improve handling and traction.

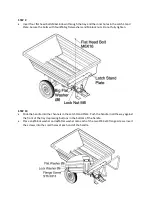

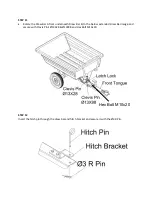

To dump material from the cart, remove the clevis pin Ø13x28 from the latch on the draw bar

and release the latch. The cart bed will then tilt backwards to empty its contents. After emptying,

pull the front of the bed down toward the cart draw bar until the latch snaps into place. Reinstall

the clevis pin in the latch to prevent accidental release.

The maximum towing speed for this cart is 10 m.p.h.