STORAGE

The tiller should be stored in a dry area, out of the reach of children.

At the end of the season, or the tiller is not going to be used for some time:

Clean the tiller.

Wipe over the metal surfaces with an oil-impregnated cloth to protect them from corrosion

(non-resinous oil) or spray a fine coat of oil onto them from a can.

Fold the top handle down for ease of storage.

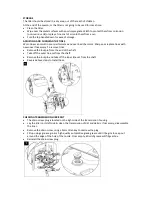

ADJUSTING AND CHANGING THE TINES

Worn tines can result in poor performance and overload the motor. Sharpen or replace tines with

new ones if necessary. To remove tines:

Remove the lock pin from the end of the shaft.

Take off the outer tine set from the shaft.

Remove the lock pin and take off the inner tine set from the shaft.

Reverse above steps to install tines.

CHECKING TRANSMISSION LUBRICANT

The drain screw plug is located on the right side of the transmission housing.

Lay the tiller on its left side & clean the transmission of dirt and debris. If necessary, disassemble

the tines.

Remove the drain screw, using a 5mm Allen key to unscrew the plug.

Fill up using a grease gun & a high quality automotive grade grease until it begins to seep out

around the edge of the hole of the nozzle. From empty, 60ml of grease will fill gearbox.

Reinstall the drain screw plug.