03/2021 V 1.0

VIEW 04

07/17

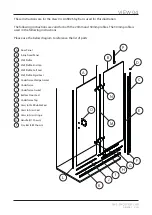

Attach the Glass to Glass Hinges in the

direction your door will open and

tighten to the Inline Panel.

Evenly tighten the screws until the

Gaskets are just “nipping” the Glass.

Tighten all the screws to 15.6N.

Check the orientation of the Cover

Plates. Adjust Clamping Plate to Suit.

DO NOT fit the Cover Plates yet.

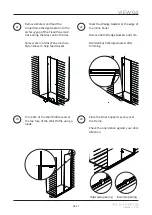

With one person inside the enclosure,

position the Door onto the Door

Supports as indicated. Ensure there is a

6mm gap between the Door and the

wall and 5mm between the two Panels.

Add Spacers to the Glass Supports in

order to level the door.

Check both Panels are level and square.

Attach the Glass to Glass Hinges to the

door and tighten.

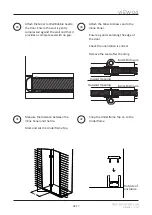

Use 5mm Packers in gap and evenly

tighten the screws until the gaskets are

just “nipped”.

Tighten all screws to 15.6N.

DO NOT fit the Cover Plates yet.

5mm Gap

(Hinge Side)

6mm Gap

(Wall Side)

Cover Plate

Clamping

Plate

25

26

27

28