P.12

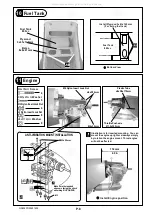

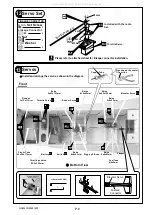

Control Throws

Adjust the control throws as shown in the diagram.

These throws are good for general flying. You can

adjust according to your personal preference.

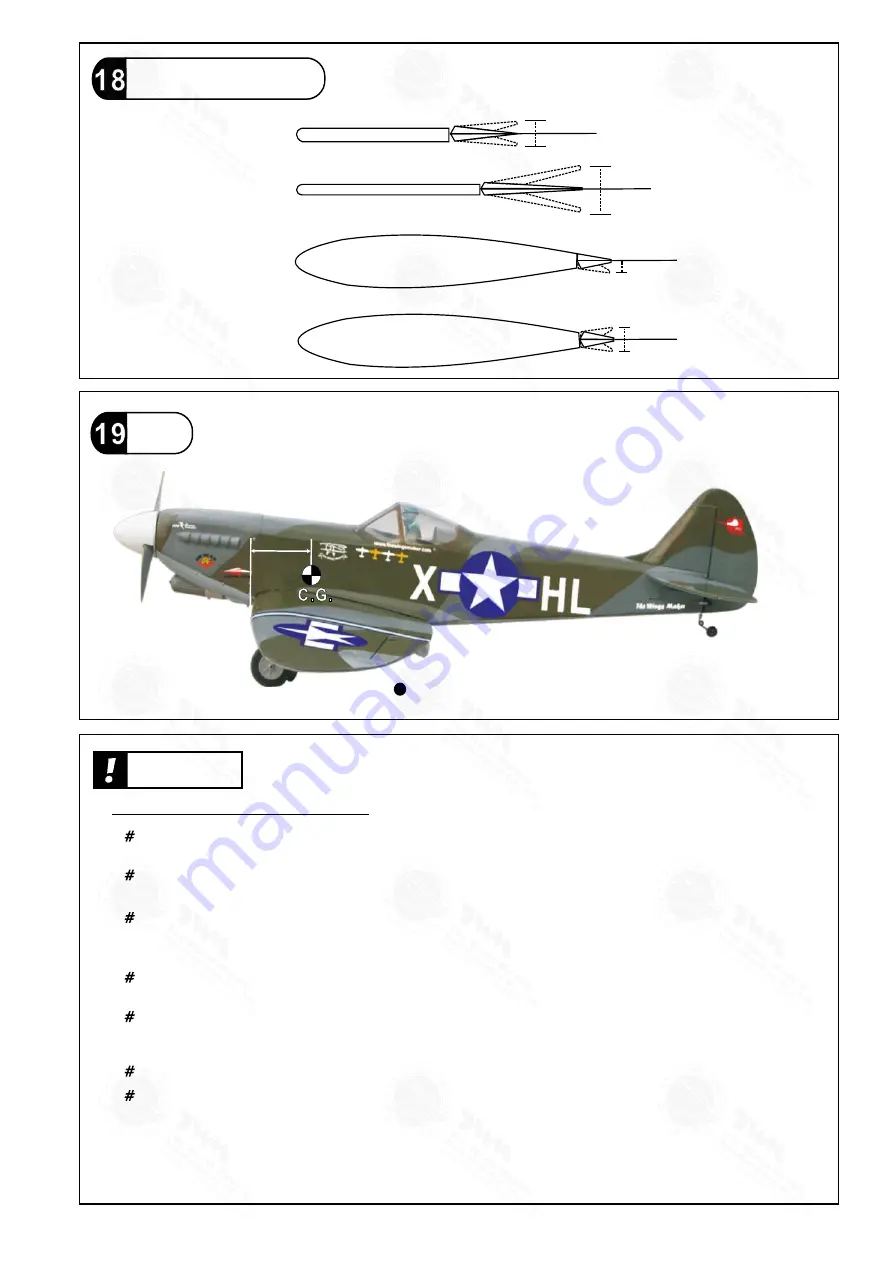

C.G.

116mm

4.6in

25mm

25mm

55mm

55mm

Elevator

Rudder

35mm

20mm

20mm

Ailerons ( away from fuselage )

Flaps (near fuselage )

Important Safety Precautions

First time flyer should never fly by himself / herself. Assistance from experienced flyer is

absolutely necessary.

Pre - flight adjustment must be done before flying, it is very dangerous to fly a badly

adjusted aircraft.

pre -

Make sure the air field is spacious, never fly the plane too close to people and never get

too close to a running propeller.

If you find wrinkles on the covering as a result of weather changes, you can use hot iron

to remove the wrinkles. Please begin with lower temperature setting and gradually raise

the temperature until the wrinkles are gone. Too hot an iron may damage the covering.

Check and re-tighten up all factory assembled screws, use thread locker if applicable.

SPITFIRE 160

is specially designed to be powered by

1.60 2

-stroke glow engine, using

a more powerful engine does not mean better performance. In fact, over powered engine

may cause severe damage and injuries.

Warning!

When Flaps are lowered, nose of model will rise. The nose-up varies with the speed at which

the model is flying when you lower the flaps and the extent to which they are lowered. Check

effect of flaps at higher altitude to avoid surprises during landing. You may apply down trim

of the elevator to compensate for the nose-up effect when lowering the flaps. Taking off with

flaps lowered is not recommended, as the increased drag may require a longer runway and

more engine power for the model.

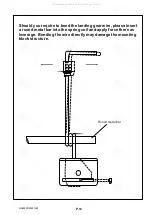

Measure C.G. with the wheels in retracted position.

http://www.theworldmodels.com/para/instruction/instructionManuals.php

The ideal C.G. position is

116mm (4.6 in)

behind the leading edge measured

at where the wing meets the fuselage. In order to obtain the C.G. specified,

add weight to the fuselage or move the battery position. Check the C.G. before

flying.

If you are converting this model to electric, please move the C.G. forward 10% of

current C.G. distance from leading edge to compensate for weight of fuel.

GA026PO29451405

All manuals and user guides at all-guides.com