A345PO32021803

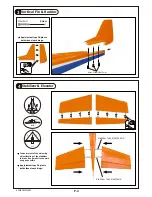

This transparent 3D template

is used for position guidance

of the actual cutting of the

pre-painted cowling.

Usage of the transparent 3D template

Simply cut the transparent 3D template to fit your engine and

exhaust pipe, then slide onto the actual cowling and use as

template to mark the openings required for final cutting.

1

2

3

4