25

The above information is for reference only. If the machine fails to work properly, please contact your local

dealer or your local authorized repair station.

All electrical installation and maintenance work in this manual must be performed by a professional electrical

engineer.,our company is not responsible for opening the panel and electric control cabinet without the

permission of the company.

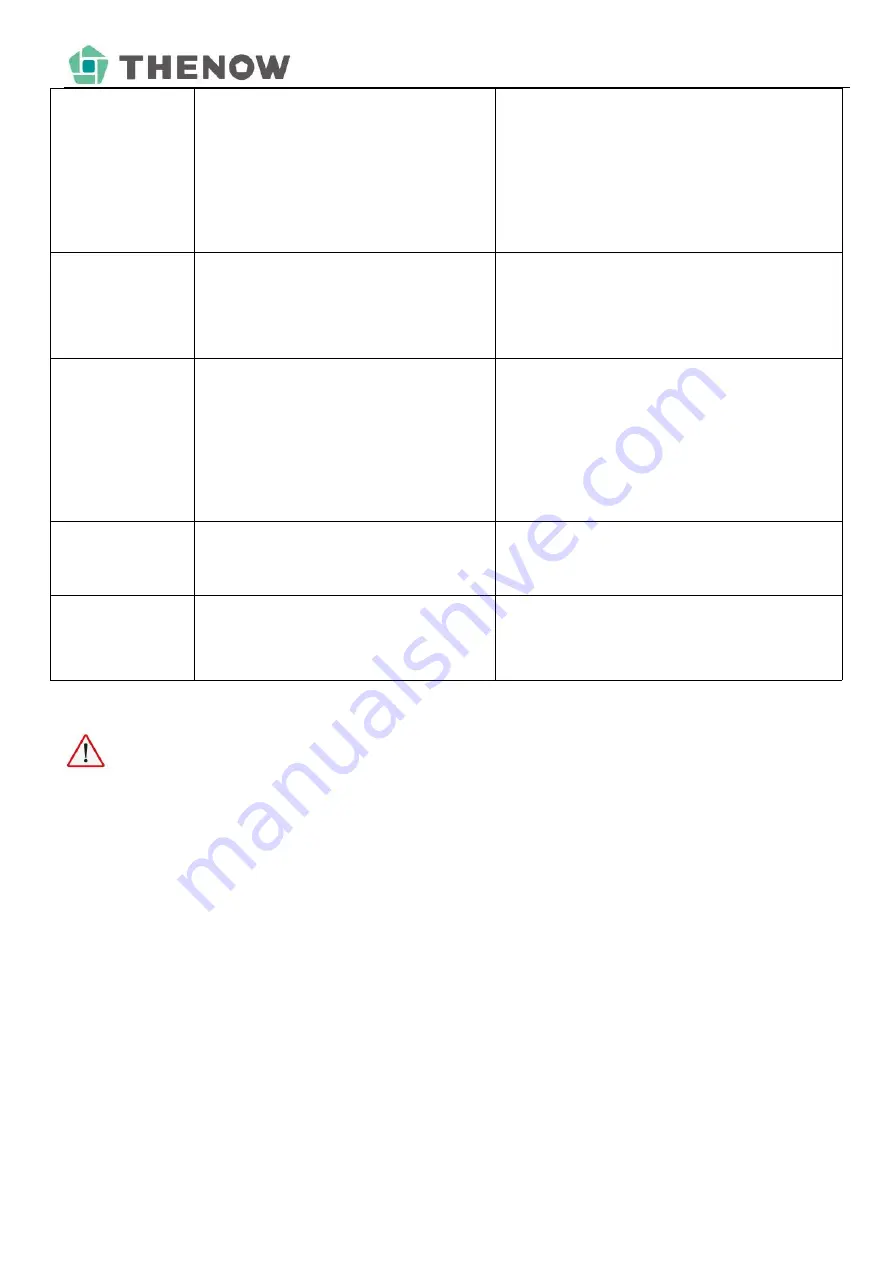

Temperature too

high

1. Setting too high.

2. Improper cabinet seals.

3. Ambient temperature too high.

4. Cabinet/room too large.

5. Fan fault.

6. Refrigerant leakage.

1. Lower setting.

2. Check gasket and door opening.

3. Check installation location.

4. Check for excessive size or the machine

model choice is improper.

5. Check both evaporator and condenser fans.

6. Add refrigerant.

Unit running too

long or continually

1. The machine model choice is

improper or improper room sealing.

2. Ambient temperature to high.

1. Check machine mode or check room

tightness.

2. Check installation location or increase

setting.

Evaporator icing

1. Evaporator airflow restricted.

2. Unit not stopping due to air leak,high

ambient temperature or low setting.

3. Low ambient temperature.

4. Bad thermostat or sensor.

5. Refrigerant leaking.

6. Expansion valve blockage.

1. Check the fan.

2. Check fr seal,door opening,ambient

temperature and setting.

3. Defrost the unit

4. Check for thermostat and sensor.

5. Check for sealed system leakage.

6. Check for low side pressure.

The fan keeps

running

1. Fan protection procedure.

2. Wrong wiring harness connection.

1. Wait 3 minutes.

2. Check harness links.

No cooling but

compressor

running

1. Refrigerant leakage.

2. Evaporator airflow restricted.

1. Check of refrigerant.

2. Check for airflow through evaporator.

Summary of Contents for HSN-J15-Z

Page 6: ...Dimensions HSN JC5 Dimensions Technical Data...

Page 7: ...Dimensions HSN J15 Z...

Page 12: ...JC5 Installation II Wine Cabinet with Large Space Internal Fan with High Speed...

Page 13: ...JC5 Installation III Wine Room...

Page 15: ...J15 Z Installation II Wine Cabinet with Large Space Internal Fan with High Speed...

Page 16: ...J15 Z Installation III Wine Room Installation...