Quest DRY 150

Quest PowerDry 4000 Pro

Installation, Operation and Maintenance Instructions

Installation, Operation and Maintenance Instructions

– Read and Save These Instructions –

This manual is provided to acquaint you with

the dehumidifier so that installation, operation

and maintenance can proceed successfully.

Ultimate satisfaction depends on the quality

of installation and a thorough understanding

of this equipment. The dehumidifier is built

around tested engineering principles and has

passed a thorough inspection for quality of

workmanship and function.

4201 Lien Rd

Phone 608-237-8400

Madison, WI 53704

Toll-Free 1-866-933-7486

www.QuestProtect.com sales@QuestProtect.com

– Read and Save These Instructions –

TS-760

11/14

quest

quest

1

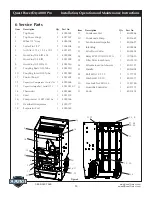

Quest PowerDry 4000 Pro:

• High capacity – 176 pints/day @ AHAM

(22 Gallons)

• Onboard humidistat for continuous humidity control

• High energy efficiency – Requires only 10 Amps of

electricity

• Pleated media filter – Standard MERV 11 filtration

reduces dust

• Optional high-efficiency filter – Removes 95% of

one-micron particles

•

Multiple Ducting Options - 12” inlet, 10” outlet.

• Reservoir pump system – Strong and dependable,

20 ft of lift

• Solid State Controls - Easy to read and operate

• Digital hour meter – Easy to read for more accurate

billing

• 25-ft power cord – No need for extension cords

• 30-ft drain hose – Pump condensate to sinks or drains

Water Removal Rate (Pints/Day)

176 pints

80˚F, 60% (AHAM)