quest

quest

1-866-933-7486

Quest PowerDry 4000 Pro

Installation, Operation and Maintenance Instructions

12

www.QuestProtect.com

sales@QuestProtect.com

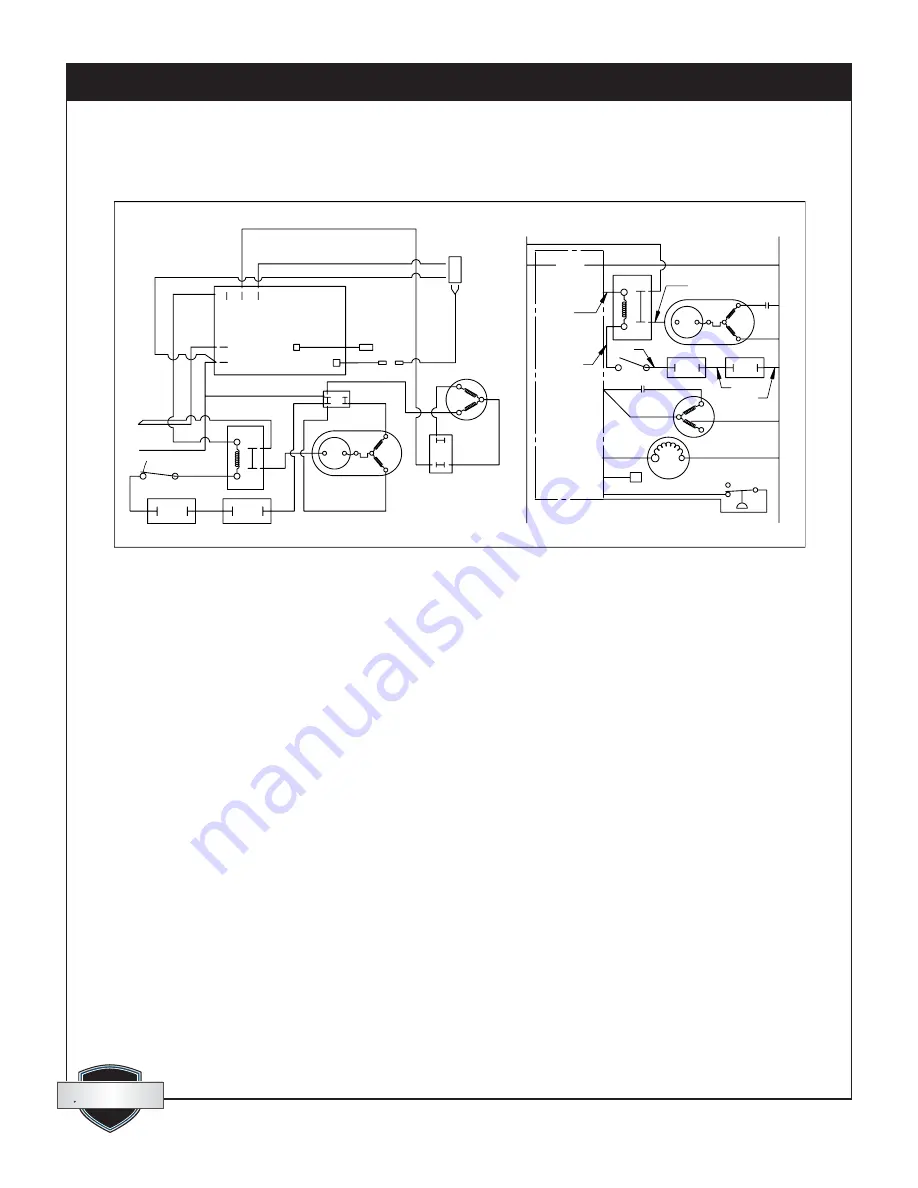

4.00

8.00

WHT.-14

RED-13

COMPRESSOR

COMP.

RELAY

BLK-10

COMP.

CAP

BLU-8

BRN-15

IMP.

CAP

BLK-16

WHT-7

WHT-2

BLK-1

NEUT. (2)

LINE (1)

EVAP

LEVEL

THERMISTOR

YEL-9,17

GRY-6

BLK-5

BLK-4

COMP

(3)

FAN

(4)

PURGE

(5)

S

R

C

BLK-1,10

WHT-2,7

BLK-10

WHT-2

BLK-1

(1)

LINE

(2)

NEU.

COMP (3)

VIO (3)

RELAY

BLK-11

C

S

R

YEL-12

WHT-7

RED-13

WHT-14

BLK-4

BRN-15

GRY-6

BLK 5

BLU-8

FAN (4)

PURGE (5)

EVAP

AMBIENT

ACTUATOR

FLOAT

THERMISTOR

VIO-3

0

4

6

1

YEL-12

IMPELLER

PUMP

BLK

GRY

BLU

YEL

BLK-16

0

4

1

6

COMPRESSOR

LEVEL

BLK-11

YEL-9,17

WHT-21

LOW PRESSURE

SWITCH

HIGH PRESSURE

SWITCH

WHT-22

WHT-23

DEHUMIDSTAT

WHT-21

WHT-22

WHT-23

NOTES:

1. MATL: VINYL FILM PER SES 182

2. CAMERA READY ARTWORK TO BE SUPPLIED OB T-STOR ENGRG DEPT

3. PROOFS TO BE APPROVED BY T-STOR ENGRG DEPT

4. COLORS: BLACK LINES & LETTERS ON WHITE BACKGROUND

PART NO:

SHEET

REV.

TITLE:

DRAWN BY

CHECKED BY

SIGNATURES / DATE

SCALE

A

1 OF 1

INCHES METRIC [MM]

.X .03 X. 1

.XX .01 X.X 0.5

.XXX .005 X.XX 0.25

ANGULAR TOL. 1

FRACTIONAL TOL. 1/64

1 INCH = 25.4 MM

DIMENSIONS ARE TOLERANCED

AS FOLLOWED:

THIRD ANGLE PROJECTION

MAT'L

Therma-Stor

LLC

P.O. Box 8050, Madison, WI 53708

REL ECO

REV ECO

REV CHANGED BY

MCN

DO NOT SCALE DRAWING. DIMENSIONS

AND TOLERANCES PER ANSI Y14.5-1994.

ALL DIMENSIONS ARE BEFORE PLATING.

DEBURR HOLES AND SHARP EDGES .005/.015.

MACHINED SURFACES 125 RMS.

THIS DRAWING IS CONFIDENTIAL AND

PROPRIETARY TO THERMA-STOR LLC. IT IS

LOANED STRICTLY ON CONDITION THAT THE

INFORMATION WILL NOT BE USED FOR THE

BENEFIT OF ANY OTHER ENTITY

TWC

11/9/2010

JZ

11/18/2010

1:1

WIRING DIAGRAM,

CONTROL BOARD, RDS22

REV CHECKED BY

SIZE

114831

LISTED

4031125

A

REVISION "A" CHANGES

- RELEASED FOR PRODUCTION

4031125

Figure 3: Electrical schematic of Quest PowerDry 4000

Pro