INSTALLATION AND SAFETY GUIDELINES

CLEARANCES

The unit must be kept clear of all combustibles.

The unit must be installed with the 4” legs supplied for proper operation.

Minimum clearance from combustible construction:

Side Back

o

Open top

12”

12”

o

Griddle

6”

12”

Minimum clearance from non-combustible:

Side Back

Open top 0” 0”

Broiler

0” 0” (For use in noncombustible locations only)

Griddle

0” 6”

LEVELING

A carpenter’s spirit level should be placed on the cooking surface and the unit leveled side-to-side, and front

to back. If it is not level, burner combustion may be erratic or the unit may not function efficiently.

AIR SUPPLY AND VENTILATION

The area around the appliance must be kept clear to avoid any obstructions of the flow of combustion and

ventilation air as well as for ease of maintenance, service, and proper appliance operation. Keep clearance for

openings into the combustion chamber and adequate air supply. Means must be provided for any commercial,

heavy duty-cooking appliance to exhaust combustion wastes to the outside of the building.

Air movement should be checked during installation. Strong exhaust fans in the hood or in the overall air

conditioning system can produce a slight draft in the room, which can interfere with pilot or burner

performance. If pilot or burner problems persist, make up air openings or baffles may have to be provided in

the room.

Filters and drip troughs should be part of any industrial hood, but consult local codes before constructing and

installing any hood. The duct system, exhaust hood, and filter bank must be cleaned on a regular basis and

kept free of grease.

ALTITUDE

The appliance input rating (BTU/hr) is for elevations up to 2000 feet. For elevations above 2000 feet, the rate

should be reduced 4% for each 1000 feet above sea level. The correct orifices are installed at the factory if

the operating altitude is known at the time of sale.

3

Summary of Contents for TC36-6

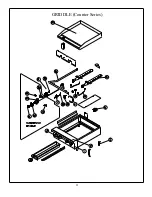

Page 10: ...9 HOT PLATE Counter Series ...

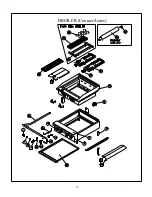

Page 12: ...GRIDDLE Counter Series 11 ...

Page 14: ...BROILER Counter Series 13 ...