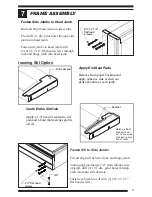

FRAME ASSEMBLY - continued

7

Outswing Sill Option

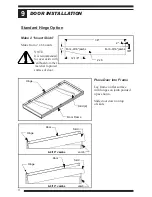

Partially Set Sill Screws

in Jambs

Drive (1) #8 x 2” flat head

screw through holes in both

side jambs until tips barely

protrude through jamb face.

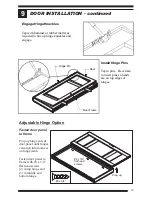

Caulk Entire Sill Gain

Apply a 1/4” bead of sealant

to sill gain and a bead that

matches upper profile of sill.

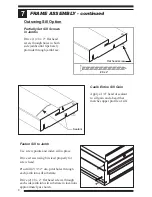

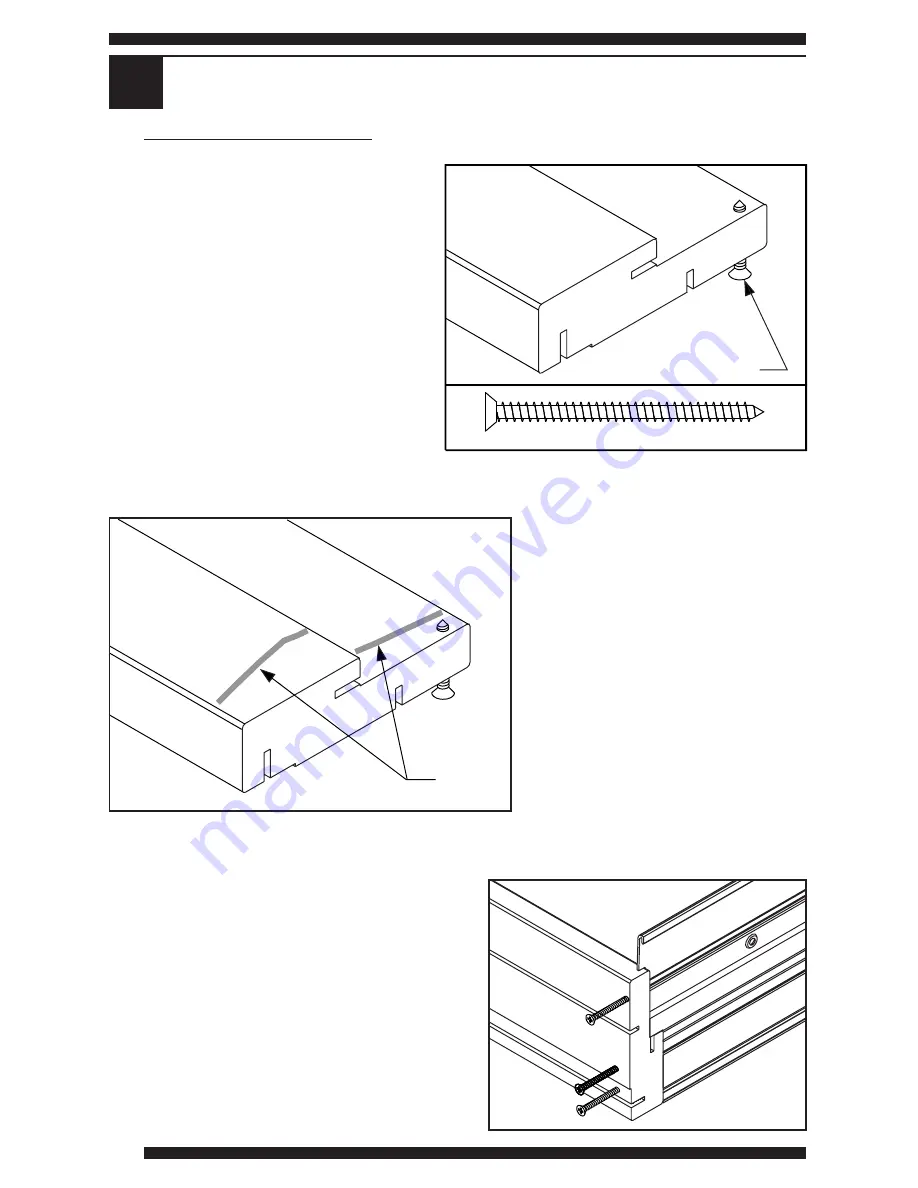

Fasten Sill to Jamb

Use screw points and index sill in place.

Drive screws using bit sized properly for

screw head.

Pre-drill (2) 3/32” dia. pilot holes through

each jamb into sill substrate.

Drive (2) #8 x 2” flat head screws through

each side jamb into sill substrate in locations

approximately as shown.

Flat head screw

#8 x 2”

Sealant

9