EX-TRACK

®

Operator Manual, Revision T-1

13

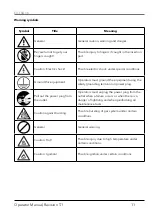

1.1.3. Safety precautions prior to handling and operation

1. Read and understand the content of this instruction manual before operating the system.

2. Before connecting the external power supply to the system, ensure that the system ON/OFF

switch is set to OFF.

3. Before operating, check to confirm correct installation, ensure that the movement of the

mechanism is unrestricted.

4. Prior to operating the system, check the work area for hazards in order to avoid accidents

5. Never move or reposition the system when in use, there is a serious risk of injury from Oxy

fuel flame and plasma arc stream.

6. Keep the rail clean and free from debris, failure to do so can result in damage to the system,

and the machine-guiding track, thus affecting the cut quality.

7. Care should be taken to prevent objects impacting/colliding with the track.

8. Prior to powering up the system, ensure that the OFF Line button is depressed (OFF position).

When the system ON/OFF switch is in the ON position, the OFF Line button should NOT be

illuminated. Failure to do so can result in injury.

9. To reduce the risk of an accident, prohibit the touching of moving parts while the system is

running.

10. DO NOT use the EX-TRACK

®

for welding purposes the circuit boards will suffer catastrophic

damage!

11. Do not operate the system during an earthquake.

12. Ensure correct connection of the oxygen and fuel gas hoses. Gas fittings/connections are

screw threaded; ensure they are correctly tightened to prevent them becoming loose during

operation.

13. If running the system in oxy fuel mode: when checking the running of system (dry run), ensure

that the preheat oxygen valve and the fuel gas valve are in the OFF position.

14. After cutting, the cutting nozzle, torch and mountings may be hot, wear gloves if handling

these parts.

15. Prevent the power cable and hoses from being trapped or crushed, ensure their free

movement.

16. The EX-TRACK

®

system is not designed for use where it is mounted on soft ground or

unstable surfaces.

17. Do not leave the system unattended when in use.

18. Hoses should be supported to reduce the risk of accidents/injury.

19. When a fuse frequently blows, to prevent damage to the system or injury to the operator, stop

all use, the cause for the fuse failure requires investigation/repair before commencing work

with the system.

Summary of Contents for EX-TRACK

Page 101: ...EX TRACK Operator Manual Revision T 1 101 Shape 1 Shape 2 Shape 3...

Page 102: ...EX TRACK Operator Manual Revision T 1 102 Shape 4 Shape 5 Shape 6...

Page 103: ...EX TRACK Operator Manual Revision T 1 103 Shape 7 Shape 8 Shape 9...

Page 104: ...EX TRACK Operator Manual Revision T 1 104 Shape 10 Shape 11 Shape 12...

Page 105: ...EX TRACK Operator Manual Revision T 1 105 Shape 13 Shape 14 Shape 15...

Page 106: ...EX TRACK Operator Manual Revision T 1 106 Shape 16 Shape 17 Shape 18...

Page 107: ...EX TRACK Operator Manual Revision T 1 107 Shape 19 Shape 20 Shape 21...

Page 108: ...EX TRACK Operator Manual Revision T 1 108 Shape 22 Shape 23 Shape 24...

Page 109: ...EX TRACK Operator Manual Revision T 1 109 Shape 25 Shape 26 Shape 27...

Page 110: ...EX TRACK Operator Manual Revision T 1 110 Shape 28 Shape 29 Shape 30...

Page 111: ...EX TRACK Operator Manual Revision T 1 111 Shape 31 Shape 32 Shape 33...

Page 112: ...EX TRACK Operator Manual Revision T 1 112 Shape 34 Shape 35 Shape 36...

Page 113: ...EX TRACK Operator Manual Revision T 1 113 Shape 37 Shape 38 Shape 39...

Page 114: ...EX TRACK Operator Manual Revision T 1 114 Shape 40 Shape 41 Shape 42...

Page 115: ...EX TRACK Operator Manual Revision T 1 115 Shape 43 Shape 44 Shape 45...

Page 116: ...EX TRACK Operator Manual Revision T 1 116 Shape 46 Shape 47 Shape 48...

Page 117: ...EX TRACK Operator Manual Revision T 1 117 Shape 49 Shape 50...

Page 118: ...EX TRACK Operator Manual Revision T 1 118 Notes...