Page 4

Appliance Installation:

Appliance Installation:

Appliance Installation:

Appliance Installation:

Appliance Installation:

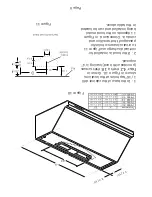

The PHE unit can be mounted on

a wall or suspended from a

cabinet. Both vertical and

horizontal discharge ar

e possible

with either mounting method.

Dischar

Dischar

Dischar

Dischar

Discharge Dirge Dirge Dirge Dirge Dir

ection:

ection:

ection:

ection:

ection:

The PHE

hood is shipped ready for vertical

discharge. To

change to horizon-

tal discharge simply move the two

plates marked

A A A A A

in Figure 1 to

the top of the hood. Each plate is

held in place by two sheetmetal

screws.

Assembly of the T

Assembly of the T

Assembly of the T

Assembly of the T

Assembly of the Transition:ransition:ransition:ransition:ransition:

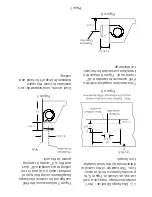

The transition supplied with the

PHE hood mounts to the top or

rear of the hood depending on the

discharge direction.

1. Align mounting holes at base

of transition with mounting holes

on 1/2” flange located at the top

or rear of the hood depending on

direction of discharge.

2. Fasten transition to hood

using 6 (4 mm x 9.5 mm) screws

(included with hood).

3. Duct tape connection between

transition and hood.

4. Remove tape holding damper

closed.

Figure 1