Page 9

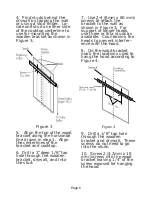

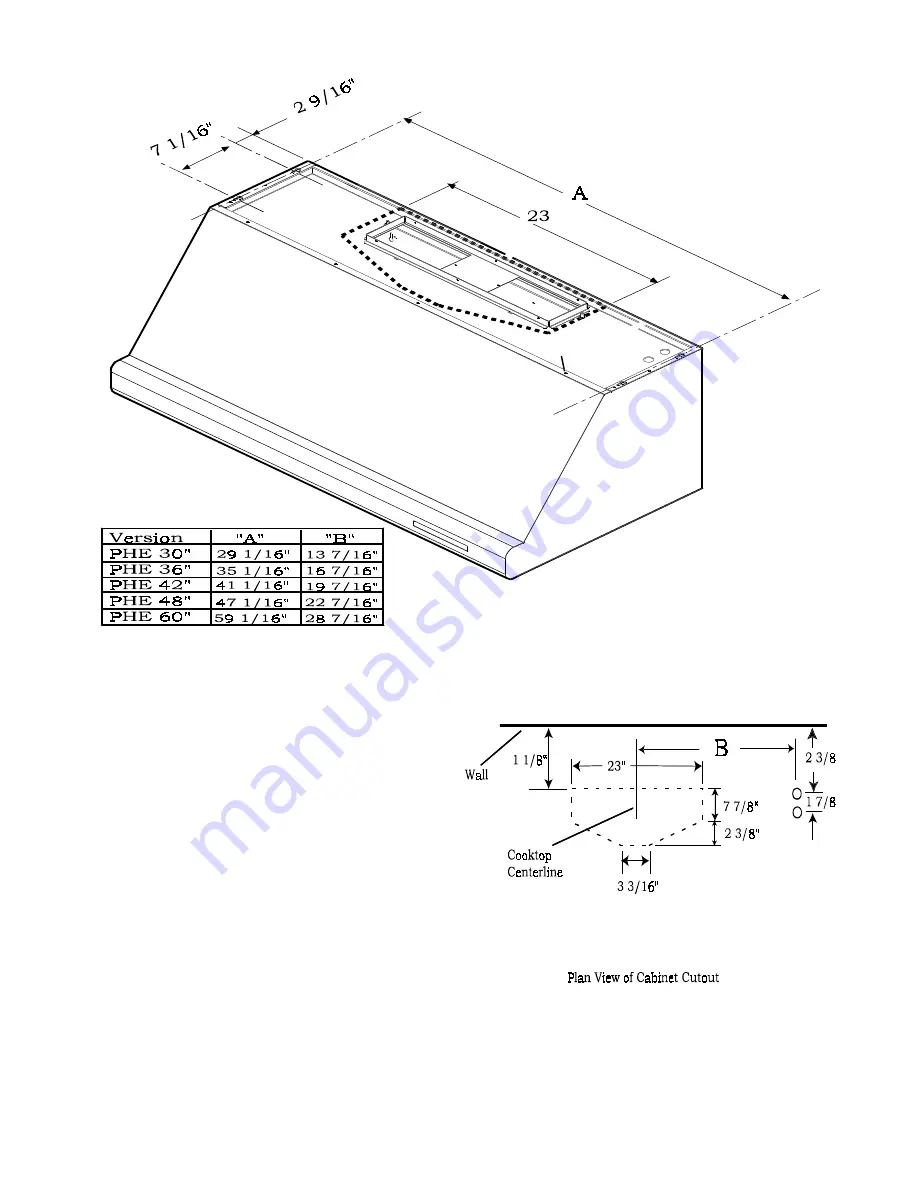

1. In the base of the cabinet drill

1/16” tap holes at the locations

shown in Figure 10. Screw in

four 4.2 mm x 18 mm

screws

(provided with hood) leaving 1/4”

exposed.

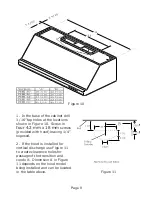

2. If the hood is installed for

vertical discharge use Figure 11

to create clearance holes for

passage of the transition and

conduit. Dimension A in Figure

11 depends on the hood model

being installed and can be located

in the table above.

Figure 10

Figure 11

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"