ARCMASTER 185 AC/DC

Feb

r

ua

r

y 20, 2006

7-1

SECTION 7:

BASIC TIG WELDING GUIDE

7.01 Explanation of “Fluttery Arc” when

AC TIG Welding on Aluminum

The following will assist in unde

r

standing the

phenomenon of A

r

c Flutte

r

, also

r

efe

rr

ed to as A

r

c

Rectification.

The basic thesis is that the flutte

r

ing is caused by lack of

oxide in the weld pool.

The oxide laye

r

on the plate

r

educed the ene

r

gy fo

r

elect

r

on emission. Elect

r

on emission f

r

om the weld pool

(DC+) causes the oxide laye

r

s to be dis

r

upted, the so-

called “cleaning action”. Howeve

r

once the cleaning action

has p

r

oduced a mi

rr

o

r

like su

r

face on the weld pool, the

effect of the oxide laye

r

is limited because the oxide laye

r

has dissipated. This makes elect

r

on emission f

r

om the

weld pool mo

r

e difficult and inc

r

eases the chance of a

r

c

instability.

This idea is suppo

r

ted by the obse

r

vation that once

flutte

r

ing sta

r

ts it can be made to stop by wo

r

king the a

r

c

away f

r

om the mi

rr

o

r

like weld pool to an a

r

ea of oxide

coated mate

r

ial. As soon as this is done the a

r

c settles

back to a stable condition. So while the a

r

c is “consuming”

oxide coated plate the instability does not occu

r

. But once

the a

r

c is stationa

r

y, the pool becomes tho

r

oughly

“cleaned” by election emission, the flutte

r

ing begins.

Tests conducted on va

r

ious types of AC TIG powe

r

sou

r

ces, Flutte

r

y A

r

c is not confined to one type of powe

r

sou

r

ce o

r

its' design, both conventional and inve

r

te

r

types

suffe

r

f

r

om the same p

r

oblem.

AC TIG on aluminum

1. The Problem:

A

r

c appea

r

s unstable and pulses o

r

flutte

r

s. ie. appea

r

s to

r

apidly change welding cu

rr

ent

.

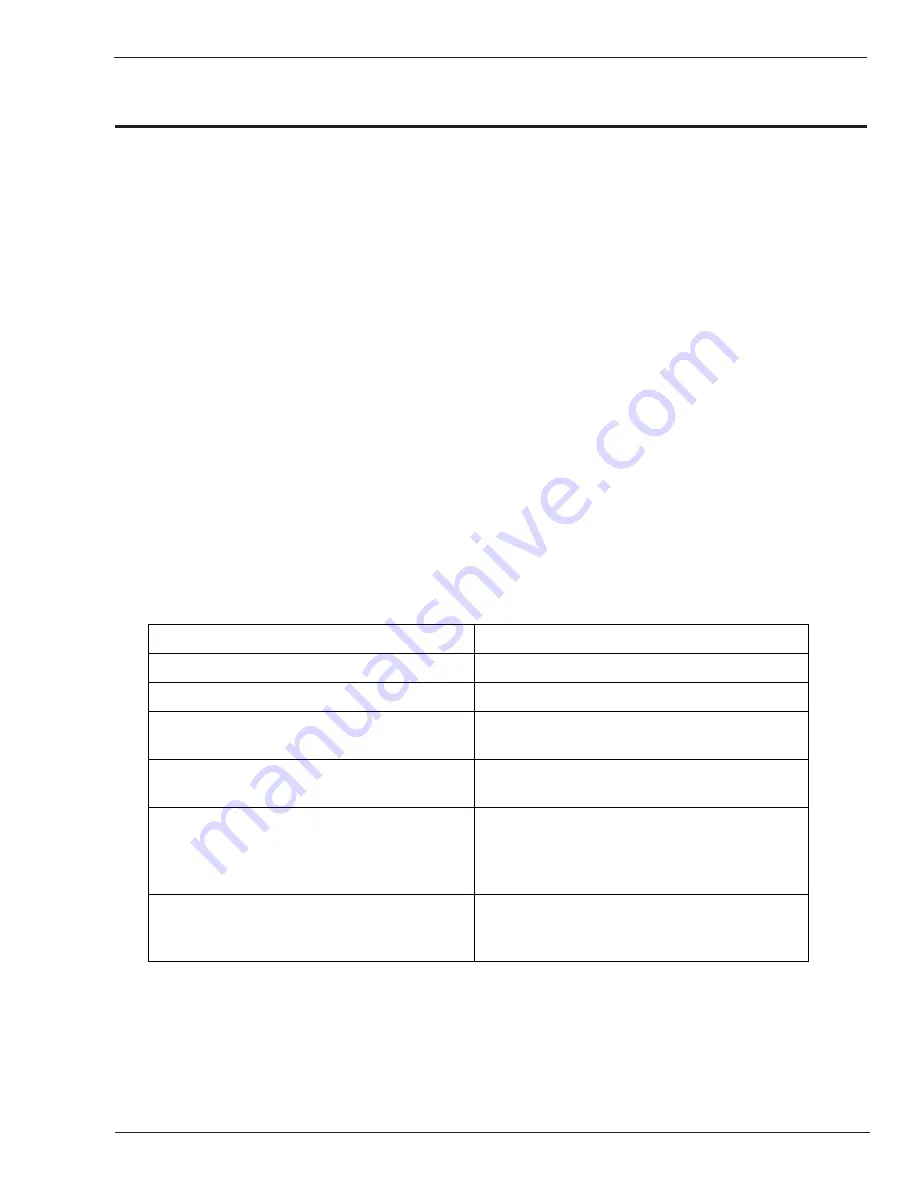

Conditions that accentuate arc flutter:

Conditions that minimizes arc flutter:

•

Cold wo

r

k piece

•

P

r

eheat the wo

r

k piece

•

Ve

r

y sho

r

t a

r

c length

•

Inc

r

ease the a

r

c length

•

Weld pool c

r

ate

r

about 0.39” to 0.47”

(10 to 12mm) diamete

r

•

Int

r

oduce fille

r

r

od mate

r

ial to the weld

pool, which int

r

oduces oxides

•

A

r

c field in one spot to p

r

oduce

“mi

rr

o

r

” clean weld pool

•

Move the weld pool a

r

ound to int

r

oduce

oxides to the weld pool

•

Inc

r

eased cleaning action

i.e. P

r

olonged oxide emission f

r

om a

stationa

r

y weld pool inc

r

eases the

likelihood of a

r

c flutte

r

•

Dec

r

ease the cleaning action by tu

r

ning

the

WAVE BALANCE

to below 50% o

r

move the weld pool a

r

ound

•

Accentuated when tungsten

r

unning

nea

r

its cu

rr

ent capacity, i.e. Molten ball

on end

•

Use a la

r

ge

r

diamete

r

tungsten elect

r

ode

Table 7-1: Reduction of A

r

c Flutte

r

2. Conclusion:

Flutte

r

y A

r

c in AC TIG is a physical phenomenon independent of machine design.

Summary of Contents for ARCMASTER 185 AC/DC

Page 24: ...ARCMASTER 185 AC DC 3 6 February 20 2006 NOTES ...

Page 34: ...ARCMASTER 185 AC DC 5 2 February 20 2006 NOTES ...

Page 58: ...ARCMASTER 185 AC DC 11 4 February 20 2006 NOTES ...

Page 69: ......

Page 72: ......