25

minerals, scale forms. The life giving properties of

water can also encourage biological growth that can

foul heat transfer surfaces.

To avoid the unwanted side effects associated with

water cooling, proper chemical treatment and

preventive maintenance is required for continuous

plant productivity.

Unwanted Side Effects of Improper Water Quality

•

Corrosion

•

Scale

•

Fouling

•

Biological Contamination

Cooling Water Chemistry Properties

•

Electrical Conductivity

•

pH

•

Alkalinity

•

Total Hardness

•

Dissolved gases

Chillers at their simplest have two main heat

exchangers: one that absorbs the heat from the

process (evaporator) and one that removes the heat

from the chiller (condenser). All our chillers use

stainless steel brazed plate evaporators. Our air-

cooled chillers use air to remove heat from the

chiller. These, as are all heat exchangers, are

susceptible to fouling of heat transfer surfaces due

to scale or debris. Fouling of these surfaces reduces

the heat-transfer surface area while increasing the

fluid velocities and pressure drop through the heat

exchanger. All of these effects reduce the heat

transfer and affect the efficiency of the chiller.

The complex nature of water chemistry requires a

specialist to evaluate and implement appropriate

sensing, measurement and treatment needed for

satisfactory performance and life. The

recommendations of the specialist may include

filtration, monitoring, treatment and control devices.

With the ever-changing regulations on water usage

and treatment chemicals, the information is usually

up to date when a specialist in the industry is

involved. Table 1 shows the list of water

characteristics and quality limitations.

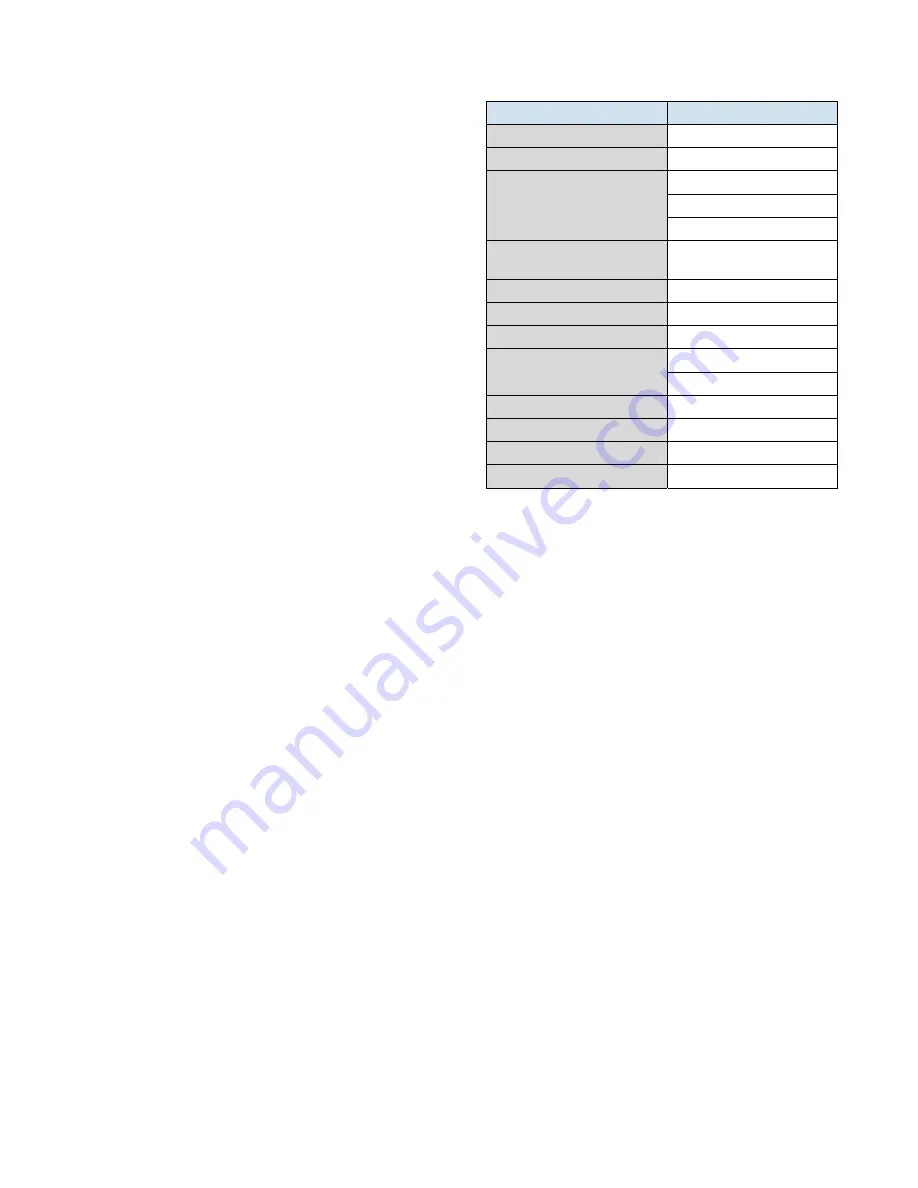

Table 10 – Fill Water Chemistry Requirements

Water Characteristic

Quality Limitation

Alkalinity (HCO

3

-

) 70-300

ppm

Aluminum (Al)

Less than 0.2 ppm

Ammonium (NH

3

)

Less than 2 ppm

Chlorides (Cl

-

)

Less than 300 ppm

Electrical Conductivity

10-500µS/cm

Free (aggressive) Carbon Dioxide

(CO

2

)†

Less than 5 ppm

Free Chlorine(Cl

2

)

Less than 1 PPM

HCO

3

-

/SO

4

2-

Greater than 1.0

Hydrogen Sulfide (H

2

S)*

Less than 0.05 ppm

Iron (Fe)

Less than 0.2 ppm

Manganese (Mn)

Less than 0.1 ppm

Nitrate (NO

3

)

Less than 100 ppm

pH 7.5-9.0

Sulfate (SO

4

2-

)

Less than 70 ppm

Total Hardness (dH)k

4.0-8.5

* Sulfides in the water quickly oxidize when exposed to air;

therefore ensure agitation does not occur when taking a water

sample. Unless tested immediately at the site, the sample will

require stabilization with a few drops of one Molar zinc acetate

solution, allowing accurate sulfide determination up to 24 hours

after sampling. A low pH and high alkalinity cause system

problems, even when both values are within the range shown. The

term pH refers to the acidity, basicity, or neutrality of the water

supply. Below 7.0, water is acidic. Neutral water contains a pH of

7.0.

† Dissolved carbon dioxide calculation is from the pH and total

alkalinity values shown below or measured on the site using a test

kit.

Dissolved Carbon Dioxide, PPM = TA x 2[(6.3-pH)/0.3] where TA =

Total Alkalinity, PPM as CaCO3

Freeze Protection

The chiller includes a flow switch for each fluid circuit

to provide protection of the evaporator from

freezing during a low-flow condition. In addition,

there are safeties in place to protect the evaporator

from freezing due to low fluid temperatures when

the unit is operating. To protect the chiller from

damage caused by freezing in the case of power

failure or a stopped state or in cases when the

anticipated set point temperature is below the

freezing point of water, use an appropriate

concentration of inhibited ethylene or propylene

glycol solution or other suitable inhibited antifreeze

solution. Ensure the antifreeze solution provides

burst protection to a temperature 10°F colder than

the lowest anticipated set point or outside ambient

air temperature.

Summary of Contents for Accuchiller KSE

Page 1: ......

Page 2: ......

Page 10: ...4 Figure 3 Mounting Platform Figure 4 Rigging...

Page 37: ...31 Notes...

Page 38: ...32...

Page 39: ......