32

To avoid the unwanted side effects associated with

water cooling, proper chemical treatment and

preventive maintenance is required for continuous

plant productivity.

Unwanted Side Effects of Improper Water Quality

•

Corrosion

•

Scale

•

Fouling

•

Biological Contamination

Cooling Water Chemistry Properties

•

Electrical Conductivity

•

pH

•

Alkalinity

•

Total Hardness

•

Dissolved gases

Chillers have two main heat exchangers: one that

absorbs the heat from the process (evaporator) and

one that removes the heat from the chiller

(condenser). All our chillers use stainless steel brazed

plate evaporators. Our air-cooled chillers use air to

remove heat from the chiller; however, our water-

cooled chillers use either a tube-in-tube or shell-in-

tube condenser which have copper refrigerant tubes

and a steel shell. These, as are all heat exchangers,

are susceptible to fouling of the heat transfer

surfaces due to scale or debris. Fouling of these

surfaces reduces the heat-transfer surface area while

increasing the fluid velocities and pressure drop

through the heat exchanger. All of these effects

reduce the heat transfer and affect the efficiency of

the chiller.

The complex nature of water chemistry requires a

specialist to evaluate and implement appropriate

sensing, measurement and treatment needed for

satisfactory performance and life that is safe and in

compliance with the ever-changing regulations on

water usage and treatment chemicals.

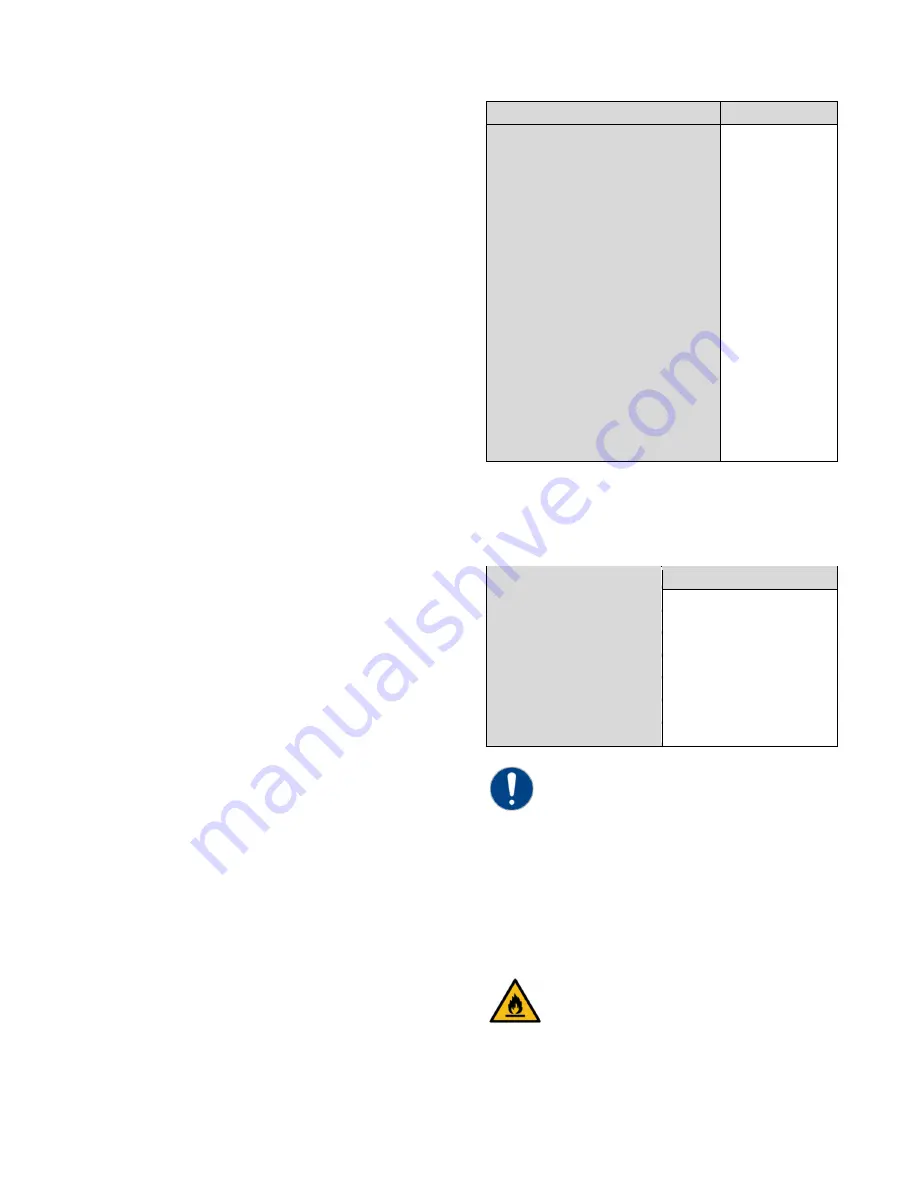

Table 10 – Fill Water Chemistry Requirements

Water Characteristic

Quality Limitation

Alkalinity (HCO

3

-

) 70-300

ppm

Aluminum (Al)

Less than 0.2 ppm

Ammonium (NH

3

)

Less than 2 ppm

Chlorides (Cl

-

)

Less than 300 ppm

Electrical Conductivity

10-500µS/cm

Free (aggressive) Carbon Dioxide (CO

2

)†

Less than 5 ppm

Free Chlorine(Cl

2

)

Less than 1 PPM

HCO

3

-

/SO

4

2-

Greater than 1.0

Hydrogen Sulfide (H

2

S)

Less than 0.05 ppm

Iron (Fe)

Less than 0.2 ppm

Manganese (Mn)

Less than 0.1 ppm

Nitrate (NO

3

)

Less than 100 ppm

pH 7.5-9.0

Sulfate (SO

4

2-

)

Less than 70 ppm

Total Hardness (dH)k

4.0-8.5

† Dissolved carbon dioxide calculation is from the pH and total

alkalinity values shown below or measured on the site using a test

kit. Dissolved Carbon Dioxide, PPM = TA x 2

[(6.3-pH)/0.3]

where TA =

Total Alkalinity, PPM as CaCO

3

Table 11 - Recommended Glycol Solutions

Chilled Water Temperature

Percent Glycol By Volume

50°F (10°C)

Not required

45°F (7.2°C)

5 %

40°F (4.4°C)

10 %

35°F (1.7°C)

15 %

30°F (-1.1°C)

20 %

25°F (-3.9°C)

25 %

20°F (-6.7°C)

30 %

CAUTION: When your application requires the use of

glycol, use industrial grade glycol specifically designed

for heat transfer systems and equipment.

Never use

glycol designed for automotive applications.

Automotive glycols typically have additives engineered

to benefit the materials and conditions found in an

automotive engine; however, these additives can gel

and foul heat exchange surfaces and result in loss of

performance or even failure of the chiller. In addition,

these additives can react with the materials of the

pump shaft seals resulting in leaks or premature pump

failures.

WARNING: Ethylene Glycol is flammable at higher

temperatures in a vapor state. Carefully handle this

material and keep away from open flames or other

possible ignition sources.