12

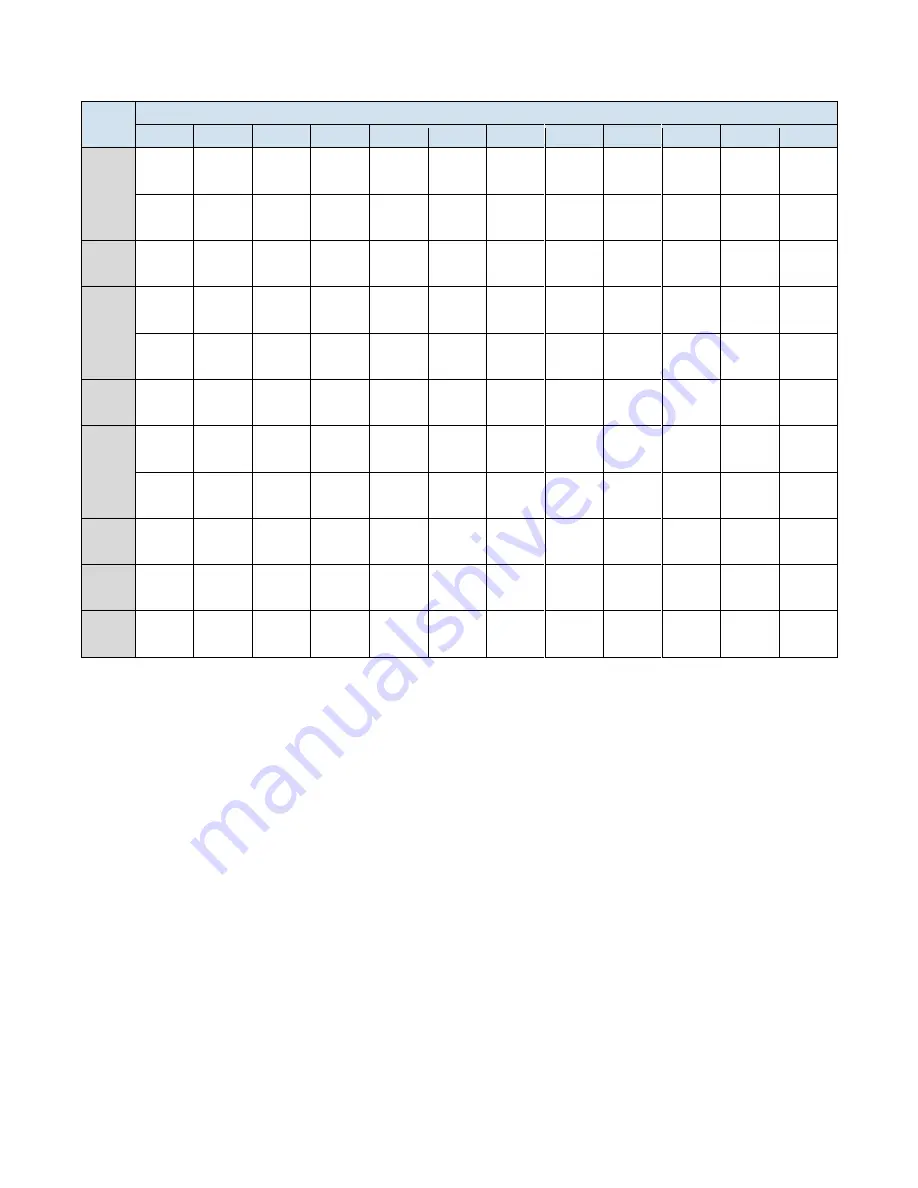

Table 5 - Upflow Discharge Line Sizes for R410A (inches OD)

Circuit

Tons

Total Equivalent Length (Ft)

25

50

75

100

125

150

175

200

225

250

275

300

10

A – 3/8 A – 3/8

A – 3/8

A – 3/8 A – 3/8 A – 3/8 A – 3/8 A – 3/8 A – 3/8 A – 3/8 A – 3/8 A – 3/8

B – 3/4

B – 3/4

B – 3/4

B – 3/4

B – 3/4

B – 3/4

B – 3/4

B – 7/8

B – 7/8

B – 7/8

B – 7/8

B – 7/8

15

A -

⅜

A – 3/8

A – 3/8

A – 3/8 A – 3/8 A – 3/8 A – 3/8 A – 3/8 A – 3/8 A – 3/8 A – 1/2 A – 1/2

B – 3/4

B – 3/4

B – 7/8

B – 7/8

B – 7/8

B – 7/8

B – 7/8

B – 7/8

B – 7/8

B – 7/8 B – 1 1/8 B – 1 1/8

20

A – 3/8 A – 3/8

A – 3/8

A – 1/2 A – 1/2 A – 1/2 A – 1/2 A – 1/2 A – 1/2 A – 1/2 A – 5/8 A – 5/8

B – 3/4

B – 7/8

B – 7/8 B – 1 1/8 B – 1 1/8 B – 1 1/8 B – 1 1/8 B – 1 1/8 B – 1 1/8 B – 1 1/8 B – 1 3/8 B – 1 3/8

25

A – 3/8 A – 3/8

A – 3/8

A – 1/2 A – 1/2 A – 1/2 A – 1/2 A – 1/2 A – 1/2 A – 1/2 A – 5/8 A – 5/8

B – 7/8

B – 7/8

B – 7/8 B – 1 1/8 B – 1 1/8 B – 1 1/8 B – 1 1/8 B – 1 1/8 B – 1 1/8 B – 1 1/8 B – 1 3/8 B – 1 3/8

30

A – 1/2 A – 1/2

A – 1/2

A – 3/4 A – 3/4 A – 3/4 A – 3/4 A – 3/4 A – 3/4 A – 3/4 A – 3/4 A – 3/4

B – 7/8

B – 7/8

B – 7/8 B – 1 1/8 B – 1 1/8 B – 1 1/8 B – 1 1/8 B – 1 1/8 B – 1 1/8 B – 1 3/8 B – 1 3/8 B – 1 3/8

40

A – 3/4 A – 3/4

A – 3/4

A – 3/4 A – 3/4 A – 3/4 A – 3/4 A – 3/4 A – 3/4 A – 3/4 A – 3/4 A – 3/4

B – 1 3/8 B – 1 3/8 B – 1 3/8 B – 1 3/8 B – 1 3/8 B – 1 3/8 B – 1 5/8 B – 1 5/8 B – 1 5/8 B – 1 5/8 B – 1 5/8 B – 1 5/8

50

A – 3/4 A – 3/4

A – 3/4

A – 3/4 A – 3/4 A – 3/4 A – 3/4 A – 3/4 A – 3/4 A – 3/4 A – 3/4 A – 3/4

B – 1 3/8 B – 1 3/8 B – 1 3/8 B – 1 3/8 B – 1 3/8 B – 1 5/8 B – 1 5/8 B – 1 5/8 B – 1 5/8 B – 1 5/8 B – 1 5/8 B – 1 5/8

60

A – 3/4 A – 3/4

A – 7/8

A – 7/8 A – 7/8 A – 7/8 A – 7/8 A – 7/8 A – 7/8 A – 7/8 A – 7/8 A – 7/8

B – 1 3/8 B – 1 3/8 B – 1 5/8 B – 1 5/8 B – 1 5/8 B – 1 5/8 B – 1 5/8 B – 1 5/8 B – 1 5/8 B – 1 5/8 B – 1 5/8 B – 1 5/8

80

A – 3/4 A – 3/4

A – 7/8

A – 7/8 A – 7/8 A – 7/8 A – 7/8 A – 7/8 A – 7/8 A – 7/8 A – 7/8 A – 7/8

B – 1 3/8 B – 1 3/8 B – 1 5/8 B – 1 5/8 B – 1 5/8 B – 1 5/8 B – 1 5/8 B – 1 5/8 B – 2 1/8 B – 2 1/8 B – 2 1/8 B – 2 1/8

100

A – 1 1/8 A – 1 1/8 A – 1 1/8 A – 1 3/8 A – 1 3/8 A – 1 3/8 A – 1 3/8 A – 1 3/8 A – 1 3/8 A – 1 5/8 A – 1 5/8 A – 1 5/8

B – 2 1/8 B – 2 1/8 B – 2 1/8 B – 2 1/8 B – 2 5/8 B – 2 5/8 B – 2 5/8 B – 2 5/8 B – 2 5/8 B – 2 1/8 B – 2 1/8 B – 2 1/8

120

A – 1 1/8 A – 1 1/8 A – 1 1/8 A – 1 3/8 A – 1 3/8 A – 1 3/8 A – 1 3/8 A – 1 3/8 A – 1 3/8 A – 1 5/8 A – 1 5/8 A – 1 5/8

B – 1 5/8 B – 1 5/8 B – 2 1/8 B – 2 5/8 B – 2 5/8 B – 2 5/8 B – 2 5/8 B – 2 5/8 B – 2 5/8 B – 2 5/8 B – 2 5/8 B – 2 5/8

Calculating Refrigerant and Oil Charge

To determine the approximate charge, first refer to

Table 6 and establish the required charge for the

condenser and chiller. Then refer to Table 7 to

determine the charge required for the field-installed

piping per circuit. The approximate charge per circuit

is therefore the sum of the values from Table 6 and

The charge required for an air-cooled condenser

using fan cycling and variable speed for head

pressure control is indeterminate due to site and

environmental variances. Because refrigerant density

increases with decreasing temperatures, the low

ambient operating charge is more (compared to the

summer charge). In the worst case of -20°F, the

charge may nearly double. The best way to assure

proper charging is, on the coldest day of the year

under full load, the charge should be up to the

second sight glass from the bottom of the receiver

with the electric expansion valve (EXV) sight glass

clear. Prolonged periods of foaming in the sight

glass may indicate a low refrigerant condition or a

restriction in the liquid line.

Note: Occasional bubbling in a sight glass may occur at a time

when load conditions are changing and the expansion valve is

adjusting to the new conditions. This momentary occurrence is a

result of normal chiller operation.

Use the sight glass to check if there is moisture in

the refrigeration circuit. If there is moisture in the

circuit, the green ring around the perimeter of the

sight glass will turn yellow. If this occurs, service

immediately.