26

User Setup – Compressor Staging

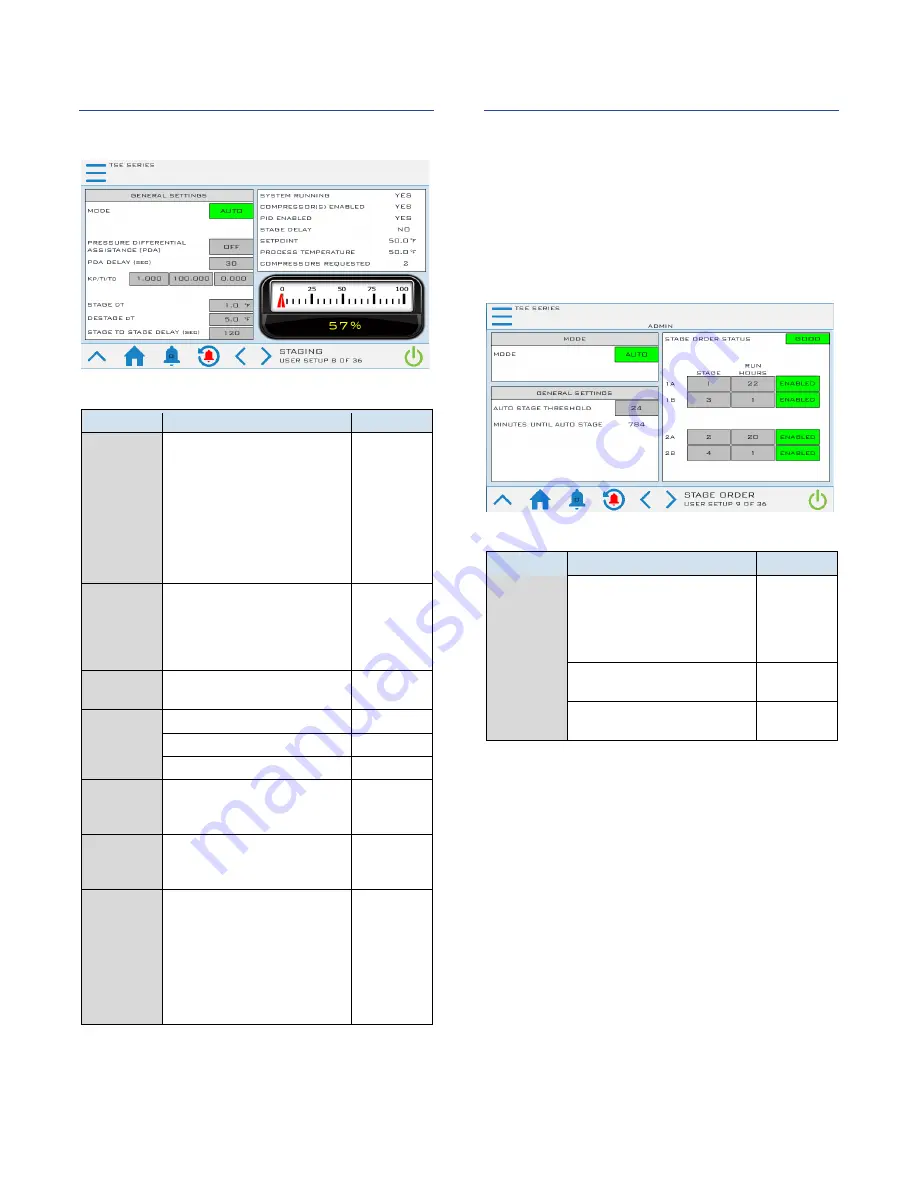

Figure 51 - User Setup – Compressor Staging Setup

Screen

Table 13 – Compressor Staging Setup Parameters

Menu Item

Description

Default Value

Staging

Mode

In Auto Mode, the control system

adjusts the number of staged

compressors relative to the

demand and available

compressors. In manual mode, the

number of staged compressors

depends on the Manual Mode

Value relative to available

compressors.

AUTO

Pressure

Differential

Assistance

(PDA)

Pressure Differential Assistance

will energize all compressors

when the circuit first starts for the

time specified in the PDA Delay

parameter.

OFF

PDA Delay

Delay time to run ll compressor

on circuit start

30 sec

Kp

Proportional PID value

1.000

Ti

Integral PID value

100.000

Td

Derivative PID value

0.000

S

tage ΔT

If the process value rises above

the set point by this differential,

the first compressor will turn on.

1°F

Destage ΔT

If the process value drops below

the set point by this differential,

all compressors turn off.

5°F

Stage to

Stage Delay

This is the minimum delay

duration between stages on

multiple compressors. During this

time delay, the demand percent

calculation ceases to allow the

impact of the newly staged

compressor to influence the

system.

120 sec

User Setup – Stage Order

Compressor Stage Order Screen

The Compressor Stage Order Screen –

depicts the stage order of the local chiller. The stage

order calculation uses the hours entered in the auto-

stage threshold parameter. The intent is to run the

compressors with the least amount of hours first to

help equalize the run hours of all the compressors

Figure 52 - User Setup – Stage Order Setup Screen

Table 14 – Stage Order Setup Parameters

Menu Item

Description

Default Value

Stage Mode

Automatic: calculates the stage

order by the AUTO STAGE

THRESHOLD parameter

Manual: Manually enter the stage

order

AUTO

Auto Stage

Threshold

The number of run hours before

recalculating the stage order

24 HOURS

Minutes Until

Auto Stage

Minutes remaining until the stage

calculation occurs

None