A40i, A60i

INTRODUCTION

Manual 0-5466

2T-2

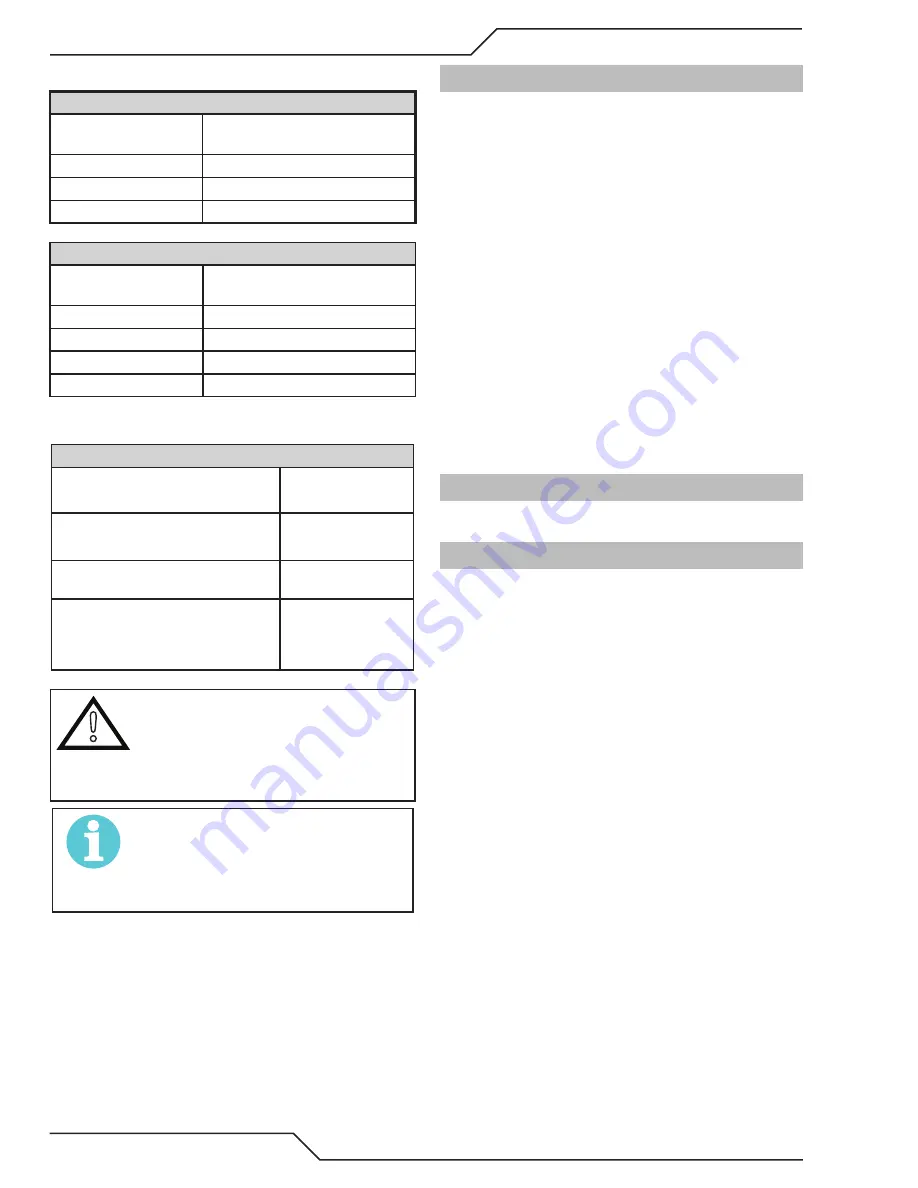

F. Torch Ratings

Automated / Machine Torch Ratings

Ambient

Temperature

104° F

40° C

Duty Cycle

100% @ 100 Amps @ 400 scfh

Maximum Current

120 Amps

Voltage (V

peak

)

500V

Manual Torch Ratings

Ambient

Temperature

104° F

40° C

Duty Cycle

100% @ 60 Amps @ 400 scfh

Maximum Current

60 Amps

Voltage (V

peak

)

500V

Arc Striking Voltage

500V

G. Gas Requirements

Manual and Mechanized Torch Gas Specifications

Gas (Plasma and Secondary)

Compressed Air

Argon

Operating Pressure

Refer to NOTE

90 - 120 psi

6.2 - 8.3 bar

Maximum Input Pressure

125 psi / 8.6 bar

Gas Flow (Cutting and Gouging)

5 - 8.3 SCFM

300 - 500 scfh

142 - 235 lpm

!

WARNING

This Torch is not to be used with

oxygen (O

2

).

The SL60QD torch should not be

used on an HF system.

NOTE!

Operating pressure varies with torch

model, operating amperage, and torch

leads length. Refer to gas pressure settings

charts for each model..

H. Direct Contact Hazard

For standoff tip the recommended standoff is 3/16

inches / 4.7 mm.

2T.04 Quick Connection Torch

The new SL60QD™ (Quick Disconnect) torch allows

for a quick change of the torch handle assembly from

the leads. To change the torch handle assembly do

the following.

1. Remove the torch handle assembly by grasping

the torch handle in one hand and the coupler nut

and leads in the other.

2. Rotate the nut a minimum of one full turn to the

left (counter closkwise) and pull the torch handle

assembly out from the leads in a straight line.

3. To reattach, grasp both as before and carefully

align the internal connecting parts.

4. Carefully press the two together in a straight line.

5. Align the mark on the coupler nut with that on

the top of the torch handle and rotate to the right

(clockwise) drawing the two together and seating

the connections inside.

2T.05 Options And Accessories

For options and accessories, see Section 6.

2T.06 Introduction to Plasma

A. Plasma Gas Flow

Plasma is a gas which has been heated to an ex-

tremely high temperature and ionized so that it

becomes electrically conductive. The plasma arc

cutting and gouging processes use this plasma to

transfer an electrical arc to the workpiece. The metal

to be cut or removed is melted by the heat of the arc

and then blown away.

While the goal of plasma arc cutting is separation of

the material, plasma arc gouging is used to remove

metals to a controlled depth and width.

In a Plasma Cutting Torch a cool gas enters Zone B,

where a pilot arc between the electrode and the torch

tip heats and ionizes the gas. The main cutting arc

then transfers to the workpiece through the column

of plasma gas in Zone C.

Summary of Contents for A40i

Page 6: ...This Page Intentionally Blank...

Page 8: ...This Page Intentionally Blank...

Page 12: ...TABLE OF CONTENTS This Page Intentionally Blank...

Page 16: ...A40i A60i WARRANTY INFORMATION Manual 0 5466 W 2 This Page Intentionally Blank...

Page 24: ...A40i A60i INTRODUCTION Manual 0 5466 2T 4 This Page Intentionally Blank...

Page 32: ...A40i A60i INSTALLATION Manual 0 5466 3 8 This Page Intentionally Blank...

Page 34: ...A40i A60i INSTALLATION Manual 0 5466 3T 2 This Page Intentionally Blank...

Page 80: ...A40i A60i OPERATION Manual 0 5466 4T 36 This Page Intentionally Blank...

Page 95: ...A40i A60i Manual 0 5466 PARTS LIST 6 3 This Page Intentionally Blank...

Page 99: ...A40i A60i Manual 0 5466 PARTS LIST 6 7 A 07994_AB 1 4 2 3 5 6 7 8 9 10 12 11 10 13...

Page 110: ...A40i A60i APPENDIX Manual 0 5466 A 10 APPENDIX 8 SYSTEM SCHEMATIC 400V 3PHASE CE Art A 13478...

Page 111: ...A40i A60i Manual 0 5466 APPENDIX A 11 Art A 13478...

Page 112: ...A40i A60i APPENDIX Manual 0 5466 A 12 APPENDIX 9 SYSTEM SCHEMATIC 208 480V 3PHASE Art A 13479...

Page 113: ...A40i A60i Manual 0 5466 APPENDIX A 13 Art A 13479...

Page 115: ...This Page Intentionally Blank...