Manual 0-2782

3-9

INSTALLATION

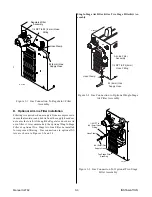

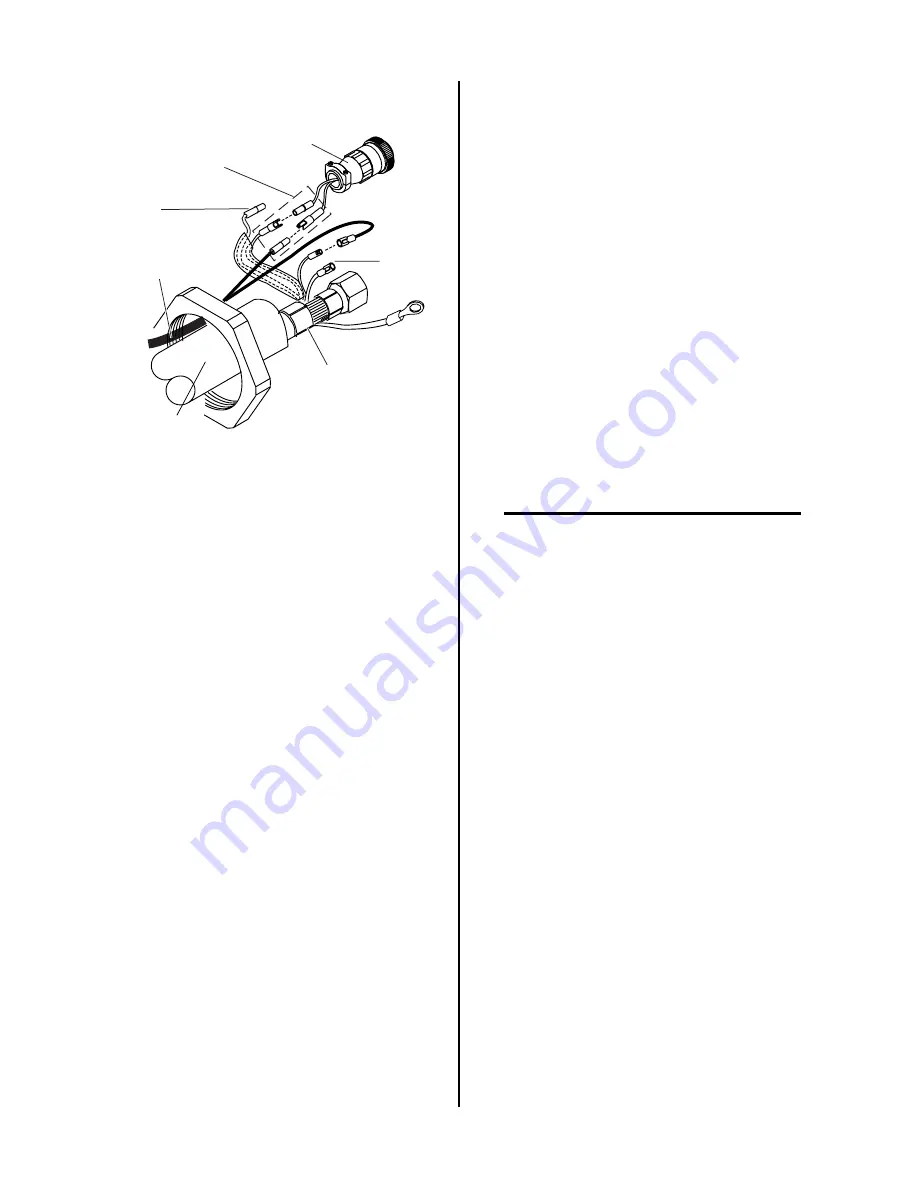

Remote Pendant

Adapter Wire

Harness

A-03676

Pilot Lead

Torch Lead

Assembly

Negative/Plasma

Lead

Control Circuit

Connectors

Open

Open

Power Supply

Adapter

Bulkhead Connection Detail - Unshielded Machine

Torch with O2B Fittings and Remote Pendant

Adapter

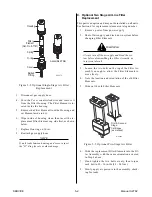

10. Tighten the Strain Relief onto the Torch Leads or

ATC Adapter Leads Assembly.

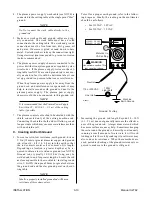

11. Connect the remote pendant to the remote pen-

dant adapter.

12. Check the torch for proper consumable parts.

3.08 Ground Connections For

Mechanized Applications

A. Electromagnetic Interference (EMI)

Pilot arc initiation generates a certain amount of electro-

magnetic interference (EMI), commonly called RF noise.

This RF noise may interfere with other electronic equip-

ment such as CNC controllers, remote controls, height

controllers, etc. To minimize RF interference, follow these

grounding procedures when installing mechanized sys-

tems:

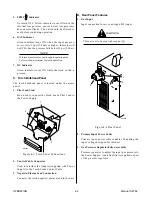

B. Grounding

1. The preferred grounding arrangement is a single point

or “Star” ground. The single point, usually on the

cutting table, is connected with 1/0 AWG (European

50 mm

2

) or larger wire to a good earth ground (refer

to paragraph ‘C’, Creating An Earth Ground). The

ground rod must be placed as close as possible to the

cutting table, ideally less than 10 ft (3.0 m), but no

more than 20 ft (6.1 m).

NOTE

All ground wires should be as short as possible.

Long wires will have increased resistance to RF

frequencies. Smaller diameter wire has increased

resistance to RF frequencies, so using a larger di-

ameter wire is better.

2. Grounding for components mounted on the cutting

table (CNC controllers, height controllers, plasma re-

mote controls, etc.) should follow the manufacturer’s

recommendations for wire size, type, and connection

point locations.

For Thermal Dynamics components it is recom-

mended to use a minimum of 10 AWG (European 6

mm

2

) wire or flat copper braid with cross section equal

to or greater than 10 AWG connected to the cutting

table frame. The connection point must be clean bare

metal; rust and paint make poor connections. For all

components, wires larger than the recommended

minimum can be used and may improve noise pro-

tection.

3. The cutting machine frame is then connected to the

“Star” point using 1/0 AWG (European 50 mm

2

) or

larger wire.

Summary of Contents for CE PAKMaster 75 XL Plus

Page 2: ......

Page 6: ......

Page 28: ...INSTALLATION 3 12 Manual 0 2782 ...

Page 47: ...Manual 0 2782 A 5 APPENDIX This page left blank ...

Page 48: ...APPENDIX A 6 Manual 0 2782 APPENDIX 5 SYSTEM SCHEMATIC A 02638 ...

Page 49: ...Manual 0 2782 A 7 APPENDIX A 02638 ...

Page 50: ......