SERVICE

5-4

Manual 0-2782

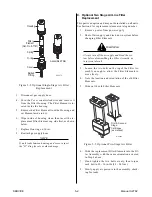

3. Excessive Dross Formation

a. Cutting speed too slow

b. Torch standoff too high from workpiece

c. Worn torch parts

d. Improper cutting current

e. Non-genuine thermal Dynamics parts used

4. Short Torch Parts Life

a. Oil or moisture in air source

b. Exceeding system capability (material too thick)

c. Excessive pilot arc time

d. Air flow too low (incorrect pressure)

e. Improperly assembled torch

f.

Non-genuine thermal Dynamics parts used

5.04 Troubleshooting Guide

A. General

Troubleshooting and repairing this unit is a process which

should be undertaken only by those familiar with high

voltage high power electronic equipment.

WARNING

There are extremely dangerous voltage and power

levels present inside this unit. Do not attempt to

diagnose or repair unless you have had training in

power electronics measurement and troubleshoot-

ing techniques.

B. Basic Troubleshooting

This manual covers a basic level of troubleshooting that

requires limited disassembly and measurements. It is

helpful for solving many of the common problems that

can arise with this system.

If major complex subassemblies are faulty, the unit must

be returned to an authorized service center for repair.

Follow all instructions as listed and complete each sec-

tion in the order presented.

For major troubleshooting and parts replacement pro-

cedures refer to PAK Master 75XL PLUS Power Supply

Service Manual 0-2783.

C. How to use this Guide

The following information is a guide to help the Cus-

tomer/Operator determine the most likely causes for

various symptoms.

This guide is set up in the following manner:

X. Symptom (Bold Type)

Any Special Instructions (Text Type)

1. Cause (Italic Type)

a. Check/Remedy (Text Type)

Locate your symptom, check the causes (easiest listed first)

then remedies. Repair as needed being sure to verify that

unit is fully operational after any repairs.

A. Main power line fuses blow as soon as main

disconnect is closed

1. Input power cable not properly connected to customer's

main power panel

a. Check that input power cable is properly con-

nected (refer to Section 3.05, Input Power Con-

nections.)

B. AC Power Indicator OFF

1. Switch at customer's main power panel in OFF posi-

tion.

a. Close main power panel switch

2. Customer's main power line fuse(s) blown

a. Check main power panel fuse(s) and replace

as required.

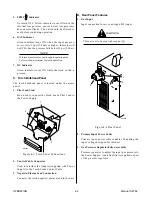

3. Unit internal fuse blown or loose

a. If blown, double check input voltage against

voltage selection (inside of unit) and replace

fuse per Section 5.05-B. If fuse blows again,

components inside the unit may be faulty.

4. Faulty components in unit

a. Return unit to an authorized service center for

repair or have qualified technician repair per

Service Manual.

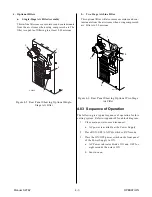

C. AC Power indicator ON; TEMP indicator ON

1. Airflow obstructed

a. Check for obstructed air flow and correct con-

dition.

2. Fan blocked

a. Check and correct condition

Summary of Contents for CE PAKMaster 75 XL Plus

Page 2: ......

Page 6: ......

Page 28: ...INSTALLATION 3 12 Manual 0 2782 ...

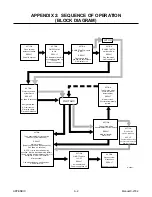

Page 47: ...Manual 0 2782 A 5 APPENDIX This page left blank ...

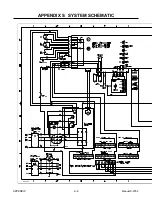

Page 48: ...APPENDIX A 6 Manual 0 2782 APPENDIX 5 SYSTEM SCHEMATIC A 02638 ...

Page 49: ...Manual 0 2782 A 7 APPENDIX A 02638 ...

Page 50: ......