CUTMASTER 20mm

SERVICE

5-4

Manual 0-5078

5.05 Basic Troubleshooting Guide

WARNING

There are extremely dangerous voltage and power levels present inside this unit. Do not attempt to diagnose or

repair unless you have had training in power electronics measurement and troubleshooting techniques.

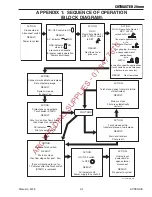

Problem - Symptom Possible Cause

Recommended Action

ON / OFF Switch is on

but the A/C Indicator

does not light

1. Primary power disconnect is in

OFF position.

2. Primary fuses / breakers are

blown or tripped.

3. Units internal fuse blown.

4. Faulty components in unit.

1. Turn primary power disconnect switch to ON position.

2. a) Have qualified person check primary fuses / breakers.

b) Connect unit to known good primary power receptacle

3. a) Replace fuse.

b) If fuse blows again, return to authorized service center for

repair or replacement.

4. Return to authorized service center for repair or replacement.

Fault indicator

flashing, 65 PSI

indicator flashing

1.Improper Input Voltage.

2. Primary input voltage problem.

3. Faulty components in unit.

1. Check for proper primary input voltage.

2. Have qualified person check primary voltage to insure it

meets unit requirements see section 2.05.

3. Return to authorized service center for repair or replacement.

TEMPERATURE

indicator on.

FAULT indicator

flashing.

1. Air flow through or around the

unit is obstructed.

2. Duty cycle of the unit has been

exceeded

3. Failed components in unit

1. Refer to clearance information – section 2.04

2. Allow unit to cool.

3. Return to authorized service center for repair or replacement.

GAS LED off, FAULT

and MIN pressure

indicators flashing.

1. Gas supply not connected to

unit.

2. Gas supply not turned on.

3. Gas supply pressure too low.

4. AIR PRESSURE CONTROL

regulator set too low.

5. Failed components in unit.

1. Connect gas supply to unit.

2. Turn gas supply on.

3. Set air supply inlet pressure to unit to 120 psi.

4. Adjust regulator to set air pressure - see section 4.02.

5. Return to authorized service center for repair or replacement.

FAULT and 70 PSI

indicators flashing.

1. Shield Cup loose.

2. Torch not properly connected to

power supply.

3. Problem in torch and leads PIP

circuit.

4. Failed components in unit.

1. Hand tighten the shield cup until it is snug.

2. Insure torch ATC is securely fastened to unit.

3. Replace torch and leads or return to authorized service center

for repair or replacement.

4. Return to authorized service center for repair or replacement.

FAULT and 75 PSI

indicators flashing.

1. Start signal is active when

ON/OFF SWITCH is turned to ON

position.

2. Problem in the torch and leads

switch circuit.

3. Failed components in unit.

1. Start can be active for one of the following:

• Hand torch switch held closed

• Hand pendant switch held closed

• CNC START signal is active low

Release the START signal source

2. Replace torch and leads or return to authorized service center

for repair or replacement.

3. Return to authorized service center for repair or replacement.

ARC WELDING SUPPLIES - 07 847 7870