CUTMASTER 20mm

INSTALLATION

3-2

Manual 0-5078

5. Pass the cable being used through the

access opening in the back panel of the

power supply. Refer to Section 2 for

power cable specifications.

CAUTION

The primary power source and power cable must

conform to local electrical code and the recom-

mended circuit protection and wiring require-

ments (refer to table in Section 2).

6. Connect the wires as follows.

• Set Jumper wires on the contactor. See

previous illustrations.

• Green / Yellow wire to Ground.

• Remaining wires to L1 and L2 input. It

does not matter what order these wires

are attached.

7. With a little slack in the wires, tighten

the through - hole protector to secure the

power cable.

8. Reinstall the Power Supply cover.

9. Connect the opposite end of individual

wires to a customer supplied plug or main

disconnect.

10. Connect the input power cable (or close

the main disconnect switch) to supply

power.

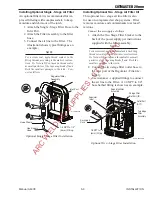

3.04 Gas Connections

Connecting Gas Supply to Unit

The connection is the same for compressed air or

high pressure cylinders. Refer to the following

two subsections if an optional air line filter is to

be installed.

1. Connect the air line to the inlet port. The

illustration shows typical fittings as an

example.

NOTE

For a secure seal, apply thread sealant to the fitting

threads, according to manufacturer's instructions.

Do not use Teflon tape as a thread sealer, as small

particles of the tape may break off and block the

small air passages in the torch.

Art # A-07943

Hose Clamp

Regulator/Filter

Assembly

Inlet Port

Gas Supply

Hose

1/4 NPT or ISO-R

to 1/4” (6mm) Fitting

Air Connection to Inlet Port

ARC WELDING SUPPLIES - 07 847 7870