Operating Manual 0-2682

13

DRAG-GUN Plasma Cutter

5. 208/230VAC Service (60Hz)

This unit operates on single phase 208 or 230VAC (±

10%) 60Hz. Units are factory set for 230V use. Ser-

vice must be fused for at least 15 amps. For informa-

tion on voltage changeover, call your local distribu-

tor.

6. Extension Cords

Extension cords must meet National Electric Code

Guidelines (and OSHA Guidelines, where applicable).

Extension cords must have the same rating as the ser-

vice and must have a three-pronged plug. Refer to

the following table for recommended cord sizes:

110 VAC & 120 VAC Service

Ext. Cord Length

Recommended Size (Min.)

Up to 50 ft. (15.2 m)

12 AWG (4 mm

2

)

Up to100 ft. (30.5 m)

10 AWG (6 mm

2

)

220 VAC Service

Ext. Cord Length

Recommended Size (Min.)

Up to 50 ft. (15.2 m)

14 AWG (2.5 mm

2

)

Up to100 ft. (30.5 m)

12 AWG (4 mm

2

)

Figure 4-1 Extension Cord Sizes for Input Voltage

E. Input Power Cable Connections

E. Input Power Cable Connections

E. Input Power Cable Connections

E. Input Power Cable Connections

E. Input Power Cable Connections

NOTE

The primary input cable is factory installed for one of the

following configurations:

• 100VAC 50Hz/110VAC 60 Hz, single phase, with

plug

• 120VAC 50Hz, single phase, no plug

• 120VAC 60Hz, single phase, with plug

• 220VAC 50Hz, single phase, no plug

• 208/230VAC 60Hz, with plug

For those units where a plug is not installed on the end of

the input power cable, connect the ends of the individual

wires to a customer supplied plug or main disconnect

per the following:

• Black (or brown) wire to Line (AC or Live)

• White (or blue) wire to Neutral (ACC)

• Green (or green-yellow) wire to Ground

F. Input Voltage Selection (For 208/230

F. Input Voltage Selection (For 208/230

F. Input Voltage Selection (For 208/230

F. Input Voltage Selection (For 208/230

F. Input Voltage Selection (For 208/230

VAC Service Only)

VAC Service Only)

VAC Service Only)

VAC Service Only)

VAC Service Only)

All 208/230 VAC units are factory set for 230 VAC. To

switch to 208VAC input power operation, contact your

local distributor.

G. Torch Consumable Parts Selection

G. Torch Consumable Parts Selection

G. Torch Consumable Parts Selection

G. Torch Consumable Parts Selection

G. Torch Consumable Parts Selection

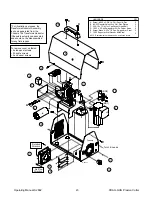

The torch consumable parts are factory installed, as shown

in Figure 4-2.

Torch Head Assembly

Electrode

Tip

Standard

Shield Cup

Gas

Distributor

PCH-10

A-02007

Figure 4-2 Exploded View of Torch Parts

To change the consumable parts, use the following pro-

cedure:

WARNING

Disconnect primary power at the source before dis-

assembling the power supply or torch.

1. Place the unit Power ON/OFF Switch to the OFF posi-

tion.

CAUTION

Consumable parts may be HOT! Torch parts may

get quite hot during normal operation. Always

wear light cutting gloves when changing torch

parts just after operating the Drag-Gun system.

2. Position the torch with the shield cup facing upward

and unscrew and remove the shield cup from the torch

head assembly (The shield cup holds the tip, gas dis-

tributor, and electrode in place).

3. Remove the tip, gas distributor, and electrode.

4. Install the electrode, gas distributor, and tip. Replace

worn parts, as necessary.

5. Install and hand tighten the shield cup until it is seated

on the torch head. If resistance is felt when installing

the cup, check the threads and parts configuration

before proceeding.

CAUTION

Improper assembly or use of nonstandard torch

parts can cause the torch head to short and may

overheat or damage the torch. Check the torch for

proper assembly and appropriate front end torch

parts.

Summary of Contents for Drag-gun

Page 2: ......