Rev 1.4 09/13/16

7

Due to variations in the ambient (temp. and R.H.) zero calibration must be initially and

periodically checked to assure best performance. (See Calibration Section)

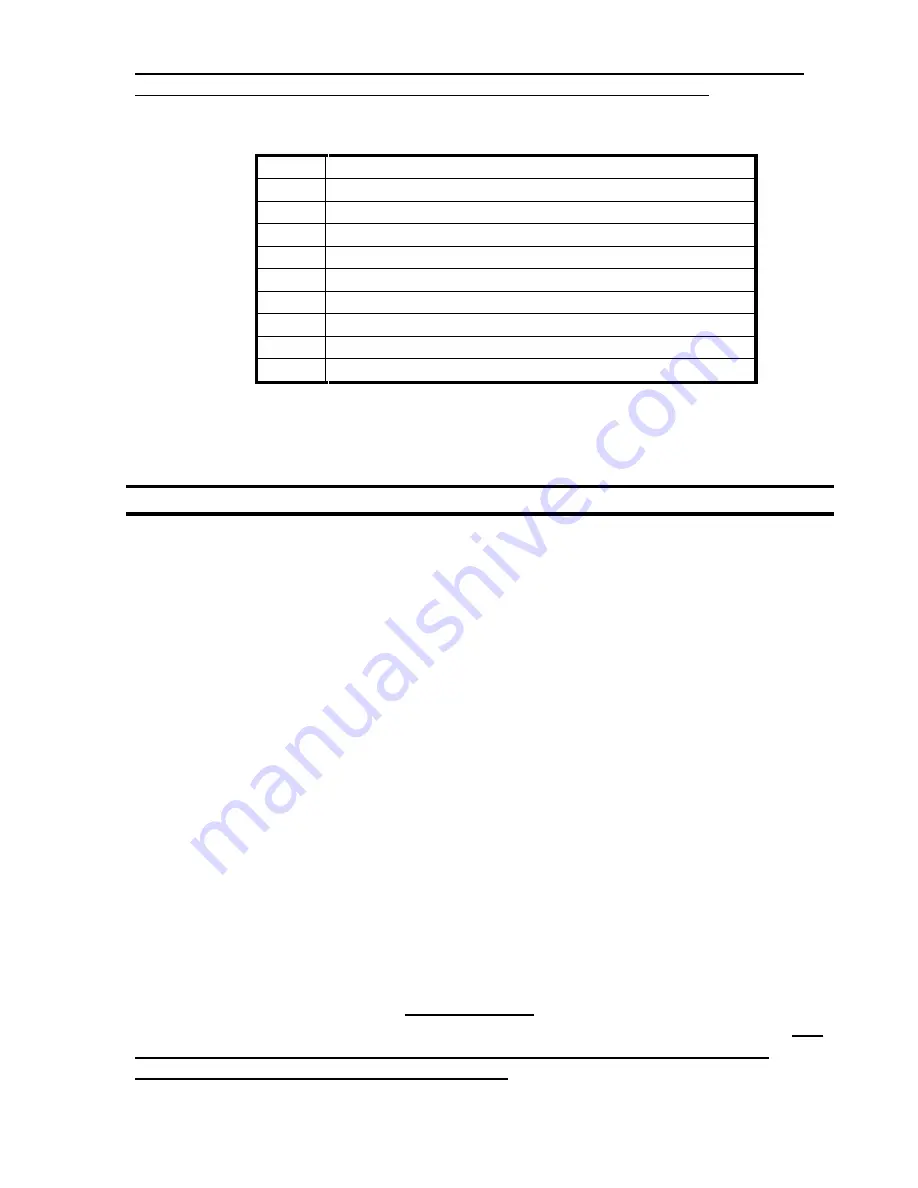

10. Locate SETUP jumpers JP-1 thru 9 on Upper Circuit Board (

Figure 2

). Select required settings

from the following menu:

JP

FUNCTION

JP-1

In house

ONLY.

JP-2

Optional AutoCalibration (See 11a)

JP-3

Set scan rate, 0-10 sec. adjustable (See 11b)

JP-4

Set gas type and channel (See 11c)

JP-5

In House Use

ONLY.

System set-up info.

JP-6

In House Use

ONLY.

Set Clock

JP-7

In House Use

ONLY

. (Contact mfg. for changes)

JP-8

Relay Latch and jumper storage. (See 11d)

JP-9

Optional Audible alarm.(See 11e)

Figure 7 - Function Jumper Settings

11. After selecting from the above, the LCD will show a new mode (SETUP, etc.) and the MAN,

ZERO and TEST push-buttons will have new functions.

Refer to Figures 2 and 5 before proceeding

a.

Auto Calibration

(Optional) select JP-2, LCD shows ACON. Haloguard

TM

compares temp.

and RH every 4 hours to compensate for changes in ambient.

b.

Scan Rate

- Rate is factory set at 4 sec. per active channel. To change, select JP-3, push

ZERO or TEST and step to desired rate. Remove jumper from JP-3.

c.

Channel and Gas Type

- See

Figure 10 - Initial Factory Setting

for channel set-up. To

change, select JP-4. Press ZERO or TEST and sequence to channel (1 thru 6) desired. Press

MAN to initiate gas type menu. Press ZERO or TEST and scroll to gas type desired (Note:

“None” selected will skip channel). Proceed to next channel and follow same process. When

finished, remove jumper from JP-4.

d.

Relay Latch Setup

- Recommended factory setting is Unlatched Mode; the alarm LEDs and

relays will return to a normal status when gas concentration goes below alarm set point. To

select Latched Mode place jumper on JP-8. Press RESET button to release alarm or check

for false alarm (Note: Alarm will be disengaged for 20 minutes).

e.

Audible Alarm

- JP-9 is factory installed to activate alarm circuit. To silence alarm remove

JP-9 jumper.

12.

TWA Integration

, (Optional). Haloguard

TM

calculates an 8 hr.

TLV-TWA,

displays this value

on LCD, activates LO alarm LED and relay if preprogrammed PPM value is exceeded.

(

Haloguard

TM

must be powered up for 8 hrs. to build database before operating).

13. Trim optional analog outputs by entering TEST mode (See

TESTING

) and turning

potentiometers on AN 1 thru AN 4 (see Figure 2 Upper Circuit Board) until output measures

5.0 or 10.0 VDC as required.

CALIBRATION

1. The Haloguard

TM

has been factory calibrated under standard conditions (70

o

F, 65% R.H.).

Due

to variations in the ambient (temp. and R.H.) zero calibration must be initially and

periodically checked to assure best performance.