Rev.1/26/98

10

CALIBRATION

Haloguard IR monitors are factory calibrated to the gas of interest; field recalibration is not required for

operation in typical machine room environments during the first twelve months of operation unless drift

exceeds more than 5ppm in a 30 day period.

For those who wish to check the factory calibration an optional Digital Calibrator and Span Gas Kit is

available. Instructions for use are included with kit

TESTING

The Haloguard IR

TM

should be tested at start-up, after any changes to alarm protocol, and after each alarm

level condition has been corrected.

During Testing, display will indicate TEST MODE

a. Alarm Test - Push TEST button five times to check all alarm levels sequentially. Alarm relays,

lights, audible and remote alarms (if equipped) will activate.

b. Reset Test - Push RESET/SILENCE button; alarm relays, audible and remote alarms (if equipped)

will become inactive for 20 minutes. Display will read RESET and indicate minutes to completion

of reset period.

TROUBLESHOOTING

The most frequent cause of nuisance alarms and faults is improper set-up, primarily due to:

a. Failure to install in accordance with instructions.

b. Not allowing sufficient warm-up time.

c. Poor sensor location.

To check Zero Calibration, fill a clean plastic trash bag with clean outside air, tie off with twist-tie, let

sample stabilize inside for 15 - 20 minutes. Insert sample tube into bag . For models equipped with scanner

allow up to 2.5 minutes per channel for clean air sample analysis

.

Observe LCD response, if dispalyed PPM value drops lower then Haloguard IR is detecting the presence of

the gas of interest or another gas which absorbs IR light at the same frequency.

Remove sample tube from bag and observe LCD response. If displayed PPM value moves higher, look for

refrigerant leaks or possible sources of interfering gases (See “Before Installation” section 3e). and relocate

sensor. Keep in mind that the Haloguard IR is much more sensitive than hand held leak detectors, it may

detect a leak when hand held units show no response

We wish to aid with any problems you might experience with the Haloguard IR

. When contacting Thermal

Gas Systems, Inc. Service Department, please have the following information ready

1. Model Number and Serial Number.

2. Description of problem.

3. Remove faceplate. Place jumper on Alarm setting function. and record settings.

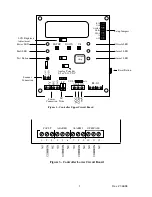

4. Measure voltage between SIG and GND.(Fig. 2) in SETUP and RUN modes Write down values

5. Advise the condition of all LED’s and all information displayed on the LCD.