4

Rev.2 1/26/98

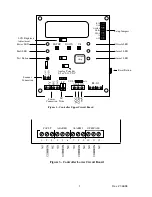

5. LED Indicators, Pushbuttons, LCD Displays, and Relays

a.

POWER LED

-

Green LED indicates Haloguard

is receiving AC power.

b.

FAULT LED and Relay

-

Indicates malfunction.

LCD indicates specific type of failure (See

Figure 4).

c.

TEST Push-button

-

Energizes Alarm LED’s & relays. Depress button five (5) times to

sequence through each alarm level.

d.

Adjustable Alarm LEDs & Relays

-

Indicate

Alarm 1&Alarm 2

-

Factory set for particular

refrigerant (See Figure 9). User adjustable as follows:

RANGE

1 PPM

INCREMENTS

10 PPM

INCREMENTS

0 - 1000 ppm

10 - 100

100 - 1000

Note: Optional TWA Integration activates Alarm 1 LED and relay when installed.

TLV-TWA Alarm is factory set and not user adjustable.

e.

OFFSCALE LED and Relay

- Factory set at 1000ppm

f.

RESET Push-button

-

Silences alarm, disables relays, and resets instrument for 20 minutes.

LCD displays *CAUTION* and RESET with 20 minute countdown. Alarms are

automatically reactivated if alarm condition is not corrected. Reset is automatically initiated

on start-up and after power failure (Except when optional UPS is provided.).

6. Optional Features:

. TWA Integration - Haloguard

calculates an 8 hr. Time Weighted Average (TLV-TWA)

,

displays this value on LCD, activates Alarm 1 LED and relay if factory set PPM value is

exceeded. Only used for gases with TLV-TWA less than 1000ppm.

HALOGUARD

IR

CONTROLLER

5 1/2”

Figure 1 - Dimensional Drawing

4”

9”

3/4”

HALOGUARD

IR

MODULE

6 1/2”

14 1/4”

(By 4” Deep)