Form: 2435-3

Arctic Installation and Operation Manual

Revision: 10

P/N 105641-01

Date: 12-1-2018

Thermal Solutions, 1175 Manheim Pike, Lancaster, PA 17601

Web:

Phone:

717-239-7642

Fax:

877-501-5212

Email:

29

(American Boiler Manufacturers Association

[ABMA], 2005. Boiler Water Quality

Requirements and Associated Steam Quality

for Industrial / Commercial and Institutional

Boilers)”

3.8.2

Objectives

The basic objectives of water treatment are:

1.

Prevent the accumulation of scale and

deposits in the boiler.

2.

Remove dissolved gases from the water.

3.

Protect the boiler against corrosion.

4.

Maintain the highest possible boiler fuel

efficiency.

5.

Decrease the amount of boiler down

time from cleaning.

3.8.3

Water softener

It is highly recommended that a zeolite water

softener be used for all make-up to the boiler.

It is intended that this be used in addition to

the chemical treatment of the boiler. Water

softening removes calcium and magnesium,

the primary causes of hard boiler scale.

3.8.4

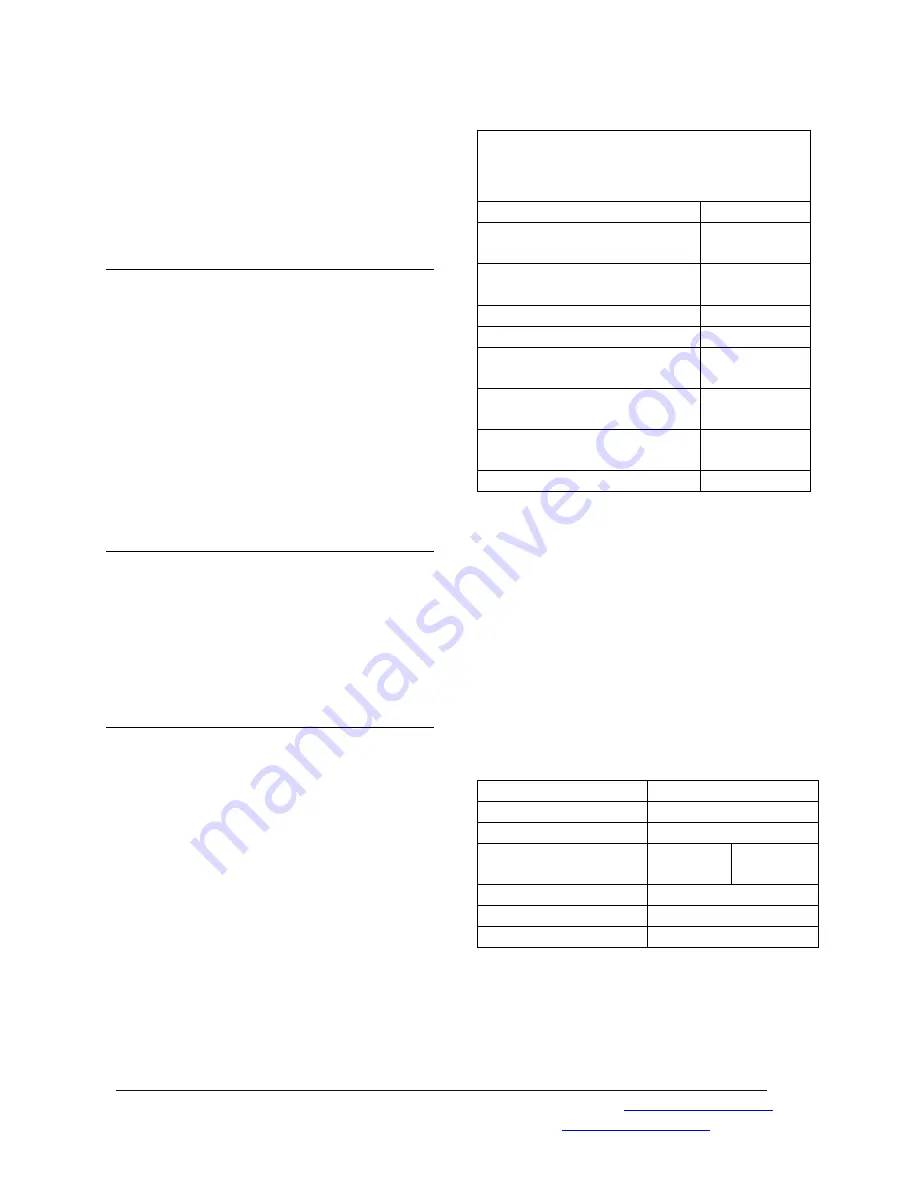

Continuous Monitoring

Water treatment should be checked and

maintained according to Table 15 whenever

the boiler is operating. The boiler operator

should be sure that the boiler is not operating

for long periods without proper water

treatment.

Water treatment may vary from season to

season or over a period of time. Therefore,

the water treatment procedure should be

checked not less than four times a year and

possibly more frequently as the local water

conditions may indicate.

See Table 14 for examples of typical chemical

agents found in untreated water along with

their potential effects.

Table 14: Chemical Agents and Effects

Compound

Effect

Calcium Carbonate,

(CaCO3)

Soft Scale

Calcium Bicarbonate

(CaHCO3)

Soft scale,

CO2

Calcium Sulphate (CaSO4)

Hard Scale

Calcium Chloride (CaCl2)

Corrosion

Magnesium Carbonate

(MgCO3)

Soft Scale

Magnesium Bicarbonate

(MgHCO4)

Corrosion,

Scale

Magnesium Sulphate

(MgSO4)

Corrosion

Silicon Dioxide (SiO2)

Hard Scale

It should be noted that water boilers may well

need chemical treatment for the first filling

plus additional periodic chemical treatment,

depending on system water losses and the

makeup requirements.

All water introduced into the boiler should be

softened and should include an oxygen

scavenger like sodium sulfite. This is required

to remove dissolved oxygen from the water.

Dissolved oxygen will cause severe system

corrosion.

Dissolved Oxygen

< 0.007 ppm

Total Iron

≤ 0.1 ppm

Total Copper

≤ 0.05

Total Hardness

≤

9

ppm

≤ 0.5

grains/gal

pH

8.3 – 10.0

Nonvolatile TOC

< 1 ppm

Oily Matter

< 1 ppm

Table 15 Recommended Feed Water

Limits