Form: 2435-3

Arctic Installation and Operation Manual

Revision: 10

P/N 105641-01

Date: 12-1-2018

Thermal Solutions, 1175 Manheim Pike, Lancaster, PA 17601

Web:

Phone:

717-239-7642

Fax:

877-501-5212

Email:

6

1

Introduction

1.1

Important Information

The following terms are used throughout this

manual to bring attention to the presence of

hazards of various risk levels, or to important

information concerning product life. It is

critical that all personnel read and follow all

the information provided in the boxes marked

DANGER, WARNING, CAUTION, and

NOTICE.

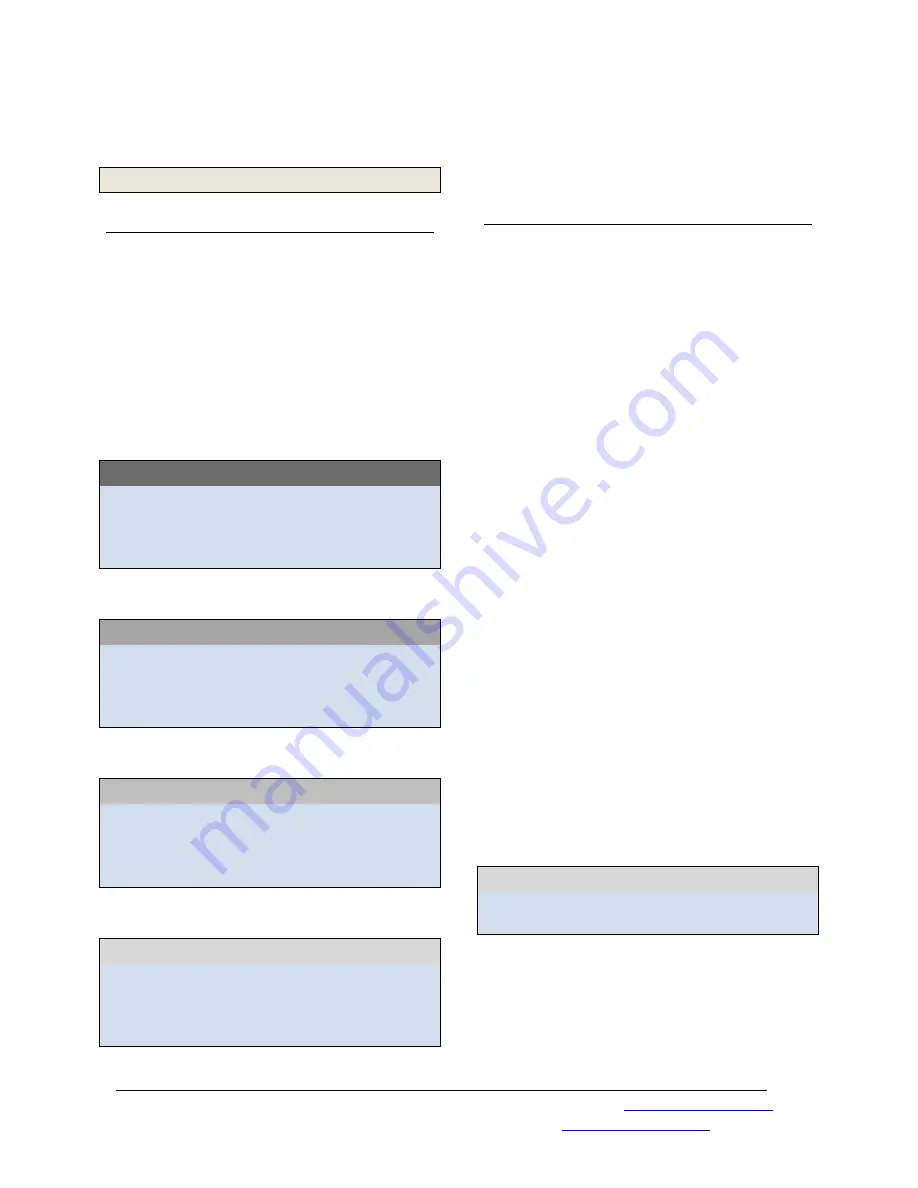

DANGER

Indicates an imminently hazardous

situation, which, if not avoided, will result

in death, serious injury or substantial

property damage

.

WARNING

Indicates

a

potentially

hazardous

situation, which, if not avoided, could

result in death, serious injury or

substantial property damage.

CAUTION

Indicates

a

potentially

hazardous

situation, which, if not avoided, may result

in moderate or minor injury or property

damage.

NOTICE

Indicates

specific

instructions

on

installation, operation, or maintenance,

which are important but not related to

personal injury hazards.

1.2

Disclaimers and Local Codes

Installation must conform to the requirements

of the authority having jurisdiction. In the

absence of such requirements, installation

must conform to the

National Fuel Gas Code,

NFPA

54/ANSI

Z223.1,

and/

or

CAN/CGA B149 Installation Codes. Where

required by the authority having jurisdiction,

the installation must conform to the

Standard

for Controls and Safety Devices for Automatically

Fired Boilers, ANSI/ ASME CSD-1.

Installation, start-up, and maintenance of this

equipment can be hazardous and requires

trained, qualified installers and service

personnel. Do not install, operate, service or

repair any components of this equipment

unless you are qualified and fully understand

all requirements and procedures. Trained

personnel refer to those who have completed

Thermal Solutions Service School training

specific to this product.

The boiler heat exchanger is manufactured

and stamped in accordance with ASME Boiler

and Pressure Vessel Code, Section IV for a

maximum allowable working pressure and

operating temperature of 160 psig (1103 kPa)

and 210 F(99 C) respectively. Aqua-stat is

factory set at 200 F (93 C).

NOTICE

Post these instructions and maintain in

legible condition.