7

BOILER MODEL

ELECTRICAL

SUPPLY (volts/Hz/phase)

blower motor (hp)

pump motor (hp)

Nominal power draw (amps)

EVCA-3000

208/60/3

2

2

14.6

230/60/3

13.9

460/60/3

7.0

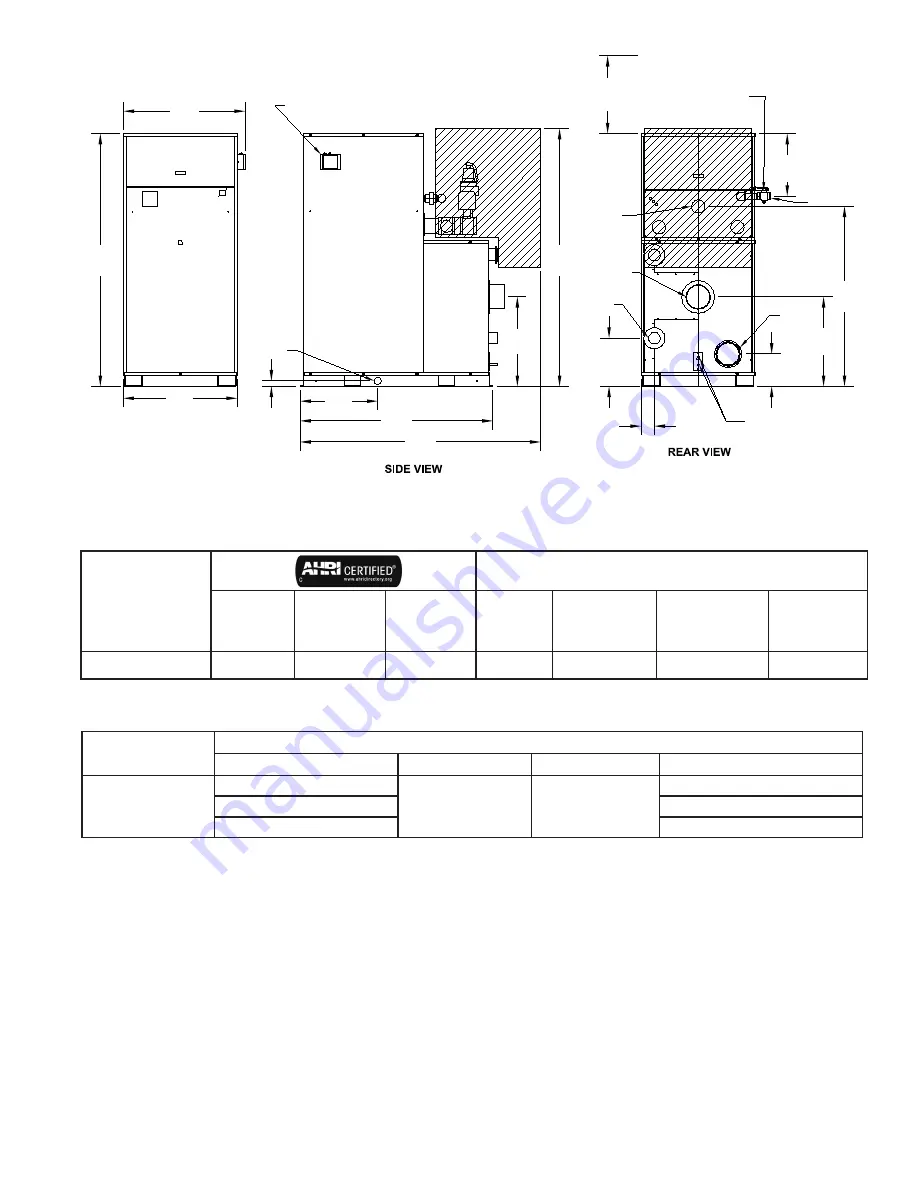

Figure 1c: Dimensions and Capacities EVCA 3000

84

.5

[2

14

6.3]

38.1

[968.2]

40.8

[1036.3]

64.5

[1638.1]

29

.9

[76

0.1]

80.5

[2044.1]

REQUIREMENT

FOR BURNER

REMOVAL

26

.5

[6

73.

1]

FRONT VIEW

26.0

[660.3]

4.4

[112.8]

29

.9

[7

60.

1]

16

.1

[4

10.

1]

10

.9

[2

75.

9]

1.9 [4

7.

3]

60

.2

[1

52

8.3]

MANUAL SHUT-OFF

VALVE

MOUNTED LOW

WATER CUT-OFF

SUPPLY TO SYSTEM,

4 Victaulic

FLUE OUTLET Ø8

SAF-T-VENT

WATER INLET

4 NPT

INLET AIR Ø8

GALVANIZED DUCT

BOILER DRAIN

1 NPT PIPE

GAS SUPPLY

2 NPT

CONDENSATE DRAINS TO BE

PIPED TO AN EXTERNAL TRAP

20

.9

[5

31.

8]

86

.1

[2

18

8.1]

Notes:

1. Piping removed for visual

clarity.

2. See notes concerning Net

AHRI Ratings on page 4.

BOILER MODEL

NUMBER

CAPACITIES

INPUT

(MBH)

GROSS

OUTPUT

(MBH)

NET AHRI

RATING

(MBH)

2

WATER

VOLUME

(gallons)

HEAT

TRANSFER

AREA (sq.ft.)

DRY WEIGHT

(lbs.)

WET

WEIGHT

(lbs.)

EVCA-3000

3,000

2,910

2,530

53.9

1,426

3,354

3,803

Summary of Contents for EVCA SERIES

Page 14: ...14 Figure 4 Typical Vertical Pressurized Venting ...

Page 16: ...16 Figure 6 Vertical Air Intake Piping Figure 5 Horizontal Air Intake Piping ...

Page 19: ...19 Figure 8 Schematic Boiler Piping ...

Page 25: ...25 Figure 9a 208 230 480V 1PH 3PH 60HZ Supply Power Wiring Schematic ...

Page 26: ...26 Figure 9b 120V 1PH 60HZ Supply Power Wiring Schematic ...

Page 27: ...27 Figure 9c Control Wiring Schematic EVCA 750 2000 ...

Page 29: ...29 Figure 9e Control Wiring Schematic EVCA 3000 ...

Page 32: ...32 Figure 10 Modular System Horizontal Air Intake Piping ...

Page 33: ...33 Figure 11 Modular System Vertical Air Intake Piping ...

Page 34: ...34 Figure 12 Modular System Typical One Pipe Water Piping ...

Page 35: ...35 Figure 13 Modular System Typical Primary Secondary Water Piping ...

Page 36: ...36 Figure 14 Modular System Typical Primary Secondary without System Pump ...

Page 37: ...37 Figure 15 Modular System Typical Reverse Return Water Piping ...

Page 38: ...38 Figure 16 Modular System Reverse Return with System Pump Only ...

Page 39: ...39 Figure 17 Modular System Typical Primary Secondary with Reverse Return ...

Page 55: ...55 Figure 18 Cleaning Secondary Heat Exchanger 1 2 ...

Page 56: ...56 This page intentionally left blank ...

Page 58: ...58 Figure 19 Boiler Combustion Chamber ...

Page 60: ...60 Figure 20 Burner Assembly FRONT VIEW TOP VIEW ...

Page 62: ...62 Figure 21a UL FM CSD 1 Main Gas Train Assembly EVCA 750 2000 ...

Page 64: ...64 Figure 21b UL FM CSD 1 Main Gas Train Assembly EVCA 3000 ...

Page 66: ...66 Figure 22a DB B Gas Train 750 Figure 22b DB B Gas Train 1000 2000 ...

Page 68: ...68 Figure 22c DB B w POC Gas Train 750 Figure 22d DB B w POC Gas Train 1000 2000 ...

Page 70: ...70 Figure 22e DB B Gas Train EVCA 3000 Figure 22f DB B w POC Gas Train EVCA 3000 ...

Page 72: ...72 Figure 23 Jacket ...

Page 74: ...74 Figure 24 EVCA 750 1000 and 1500 Secondary Heat Exchanger and Housing ...

Page 78: ...78 Figure 25b EVCA 3000 Secondary Heat Exchanger and Housing ...

Page 80: ...80 Figure 26 Control Panel Assembly ...

Page 82: ...82 Figure 27 Bishop Pilot Assembly ...

Page 97: ...97 NOTES ...

Page 98: ...98 NOTES ...

Page 99: ...99 NOTES ...