95

H.

COMMUNICATION MENU

EVCA Modulating Fire Test Procedures and Specifications

APPENDIX D (Cont…) – TSBC

TM

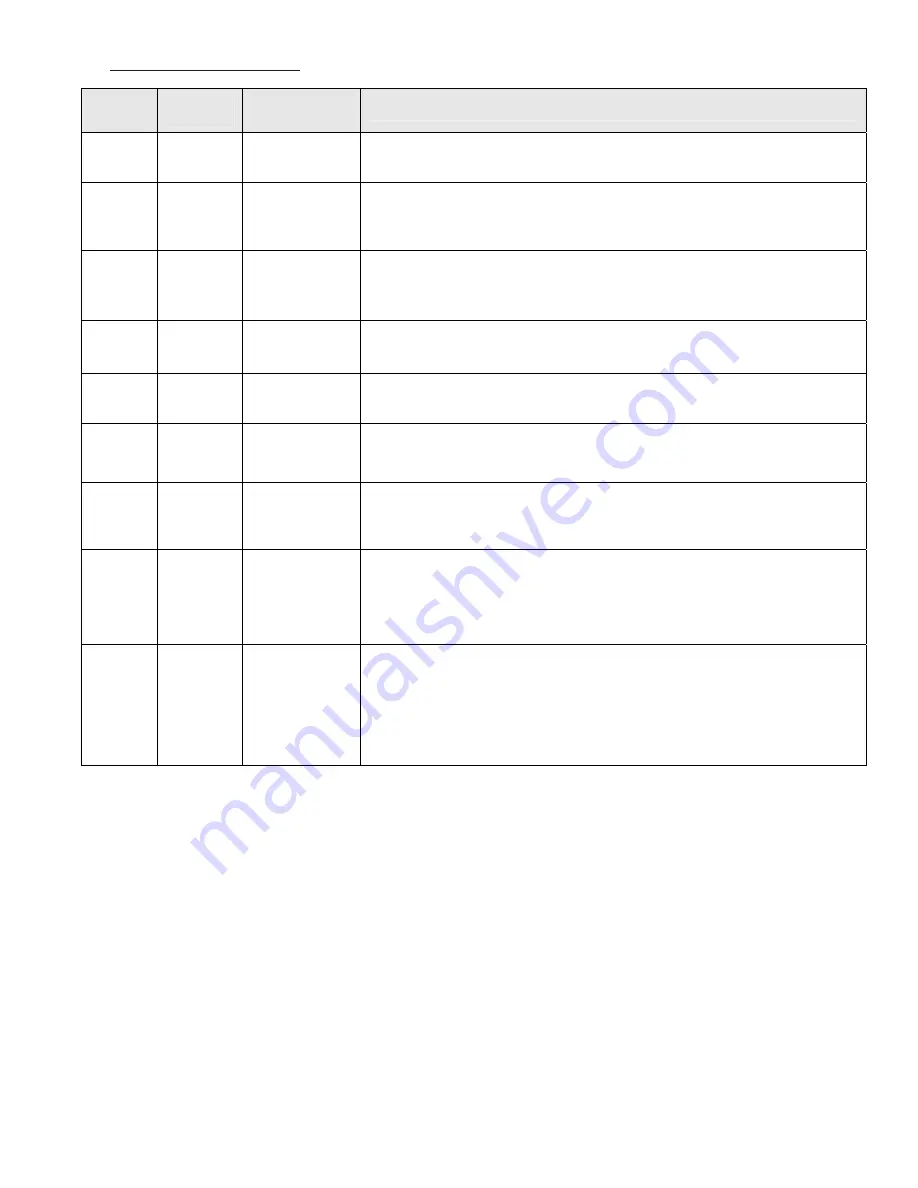

COMMUNICATIONS Menu

Display

Factory

Settings

Range/Choices

Description

Protocol

Peer to

Peer

Peer to Peer

Modbus

Selects between Peer-To-Peer (multiple boiler Lead/Lag control network) and a

Modbus slave communication.

Modbus

Address

1

1 to 247

Each boiler must be given a unique address.

Only visible when

Protocol

equals Modbus.

Baud

Rate

19.2

9.6

19.2

38.4

Units are 1000 Bits Per Second (KBPS).

Only visible when

Protocol

equals Modbus.

Parity

Odd

Odd

Even

None

Only visible when

Protocol

equals Modbus.

Timeout

30

1 to 120

Only visible when

Protocol

equals Modbus.

Messages

Rcvd

Diagnostic tool used to confirm wiring and Modbus master configuration.

Only visible when

Protocol

equals Modbus.

Messages

Sent

Diagnostic tool used to confirm wiring and Modbus master configuration.

Only visible when

Protocol

equals Modbus.

Boiler

Address

1

1 to 8

Each boiler must be given a unique address. The boiler address assignment

determines the boiler sequencing order. A value of 0 disables the network

communications.

Only visible when

Protocol

equals Peer to Peer.

Online

Status

xxxxxxxx

Each space can be either the boiler address or a ‘ - ‘ depending on whether there

is a boiler of that address on-line.

Example: - - 6 - - - 321 indicates that boilers 6,3,2 and 1 are online

Only visible when

Protocol

equals Peer to Peer.

Page 18 of 22

.

Summary of Contents for EVCA SERIES

Page 14: ...14 Figure 4 Typical Vertical Pressurized Venting ...

Page 16: ...16 Figure 6 Vertical Air Intake Piping Figure 5 Horizontal Air Intake Piping ...

Page 19: ...19 Figure 8 Schematic Boiler Piping ...

Page 25: ...25 Figure 9a 208 230 480V 1PH 3PH 60HZ Supply Power Wiring Schematic ...

Page 26: ...26 Figure 9b 120V 1PH 60HZ Supply Power Wiring Schematic ...

Page 27: ...27 Figure 9c Control Wiring Schematic EVCA 750 2000 ...

Page 29: ...29 Figure 9e Control Wiring Schematic EVCA 3000 ...

Page 32: ...32 Figure 10 Modular System Horizontal Air Intake Piping ...

Page 33: ...33 Figure 11 Modular System Vertical Air Intake Piping ...

Page 34: ...34 Figure 12 Modular System Typical One Pipe Water Piping ...

Page 35: ...35 Figure 13 Modular System Typical Primary Secondary Water Piping ...

Page 36: ...36 Figure 14 Modular System Typical Primary Secondary without System Pump ...

Page 37: ...37 Figure 15 Modular System Typical Reverse Return Water Piping ...

Page 38: ...38 Figure 16 Modular System Reverse Return with System Pump Only ...

Page 39: ...39 Figure 17 Modular System Typical Primary Secondary with Reverse Return ...

Page 55: ...55 Figure 18 Cleaning Secondary Heat Exchanger 1 2 ...

Page 56: ...56 This page intentionally left blank ...

Page 58: ...58 Figure 19 Boiler Combustion Chamber ...

Page 60: ...60 Figure 20 Burner Assembly FRONT VIEW TOP VIEW ...

Page 62: ...62 Figure 21a UL FM CSD 1 Main Gas Train Assembly EVCA 750 2000 ...

Page 64: ...64 Figure 21b UL FM CSD 1 Main Gas Train Assembly EVCA 3000 ...

Page 66: ...66 Figure 22a DB B Gas Train 750 Figure 22b DB B Gas Train 1000 2000 ...

Page 68: ...68 Figure 22c DB B w POC Gas Train 750 Figure 22d DB B w POC Gas Train 1000 2000 ...

Page 70: ...70 Figure 22e DB B Gas Train EVCA 3000 Figure 22f DB B w POC Gas Train EVCA 3000 ...

Page 72: ...72 Figure 23 Jacket ...

Page 74: ...74 Figure 24 EVCA 750 1000 and 1500 Secondary Heat Exchanger and Housing ...

Page 78: ...78 Figure 25b EVCA 3000 Secondary Heat Exchanger and Housing ...

Page 80: ...80 Figure 26 Control Panel Assembly ...

Page 82: ...82 Figure 27 Bishop Pilot Assembly ...

Page 97: ...97 NOTES ...

Page 98: ...98 NOTES ...

Page 99: ...99 NOTES ...