6

www.thermaltronics.com support email: support@thermaltronics.com

UNPACKING/ASSEMBLY/OPERATION

Assembly (Continued)

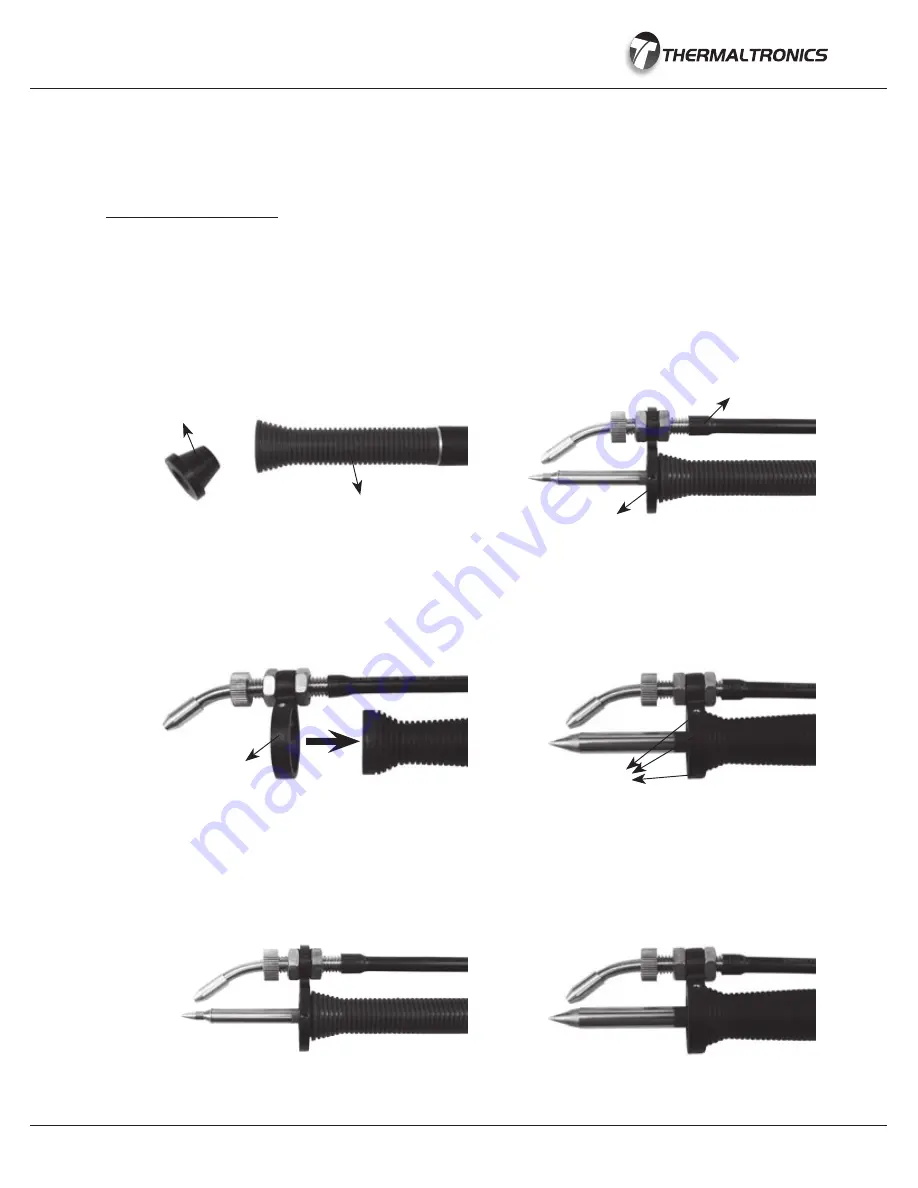

7. Attach the (5) Guide Pipe Assembly onto the soldering hand piece using the (4c) Guide Clip. (See:

Guide Pipe Assembly)

●

AF-KIT-1, AF-KIT-2 - The (4c) Guide Clip can be screwed onto the soldering hand piece by

hand.

●

AF-KIT-3 - Attach the (4c) Guide Clip to the soldering hand piece. Use a flat-blade screw driver

to secure the (4C) Guide Clip to the soldering hand piece.

●

AF-KIT-1M, AF-KIT-2T, AF-KIT-3K, AF-KIT-3KM, AF-KIT-3P, AF-KIT-3PM, AF-KIT-3SM -

No assembly of Guide Pipe is required, the Guide Pipe Assembly is already attached to the

soldering hand piece by default.

(1) Remove the hand piece top by rotating in

counter clockwise motion.

(2) Install the Guide Pipe Assembly to the

hand piece.

(1) Push the Guide Clip onto the hand piece

(2) Use a flat-blade screw driver to tighten

the three screws on the Guide Clip.

Hand Piece Top

Hand Piece

Guide Clip

Guide Pipe Assembly

Guide Clip

Fasten Screws

No Assembly Required

Summary of Contents for AF-KIT

Page 1: ...USER MANUAL AF KIT AUTO SOLDER FEEDER KIT www thermaltronics com ...

Page 2: ......

Page 14: ......

Page 15: ......

Page 16: ...Support Email support thermaltronics com www thermaltronics com ...