Thermann Installer's Manual

Gas Continuous Flow Condensing Water Heaters

12

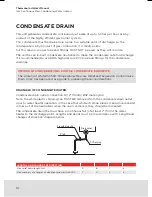

This unit generates condensate continuously at a rate of up to 5 litres per hour as a by-

product of the highly efficient gas burner system.

This condensate must be drained via a pipe to a suitable point of discharge. As the

condensate is a by-product of gas combustion, it is mildly acidic.

For this reason, copper tube and fittings MUST NOT be used, as they will corrode.

The unit has an in-built condensate neutralizer to make the condensate safe for discharge.

It is recommended to use DN15 high pressure PVC pipe and fittings for the condensate

drain line.

CONDENSATE DRAIN

IMPORTANT CONSIDERATIONS FOR THE CONDENSATE DRAIN PIPE

The content of AS/NZS 3500 'Temperature/Pressure Relief and Expansion Control Valve

Drain Lines' has been used as a guide in preparing these considerations.

DRAINAGE OF CONDENSATE WATER

Condensate drain outlet connection, R1/2" (15mm) BSP male nylon.

Note: the white plastic shipping cap MUST BE removed from the condensate drain outlet

prior to water heater operation. In the case that white-ish stone pieces (calcium carbonate)

comes out of the neutralizer when the cap is removed, they should be discarded.

The condensate drain line must have a continuous fall (of at least 2°) from the water

heater to the discharge point. Lengths and bends must be in accordance with 'Length and

changes of direction' diagram below.

LENGTHS AND CHANGES OF DIRECTION

Max relief drain length (m)

9

8

7

6

Max numbers of changes of direction (greater than 45°)

3

4

5

6

Drain outlet

2° fall

Fix with pipe clip

PVC piping

Summary of Contents for 26LP50C

Page 2: ...Thermann Installer s Manual Gas Continuous Flow Condensing Water Heaters ...

Page 27: ...27 27 27 ...

Page 28: ...20832270 K ...