14

INSTALLATION INSTRUCTIONS

26

_0

3_

01

_18

79

1

2

3

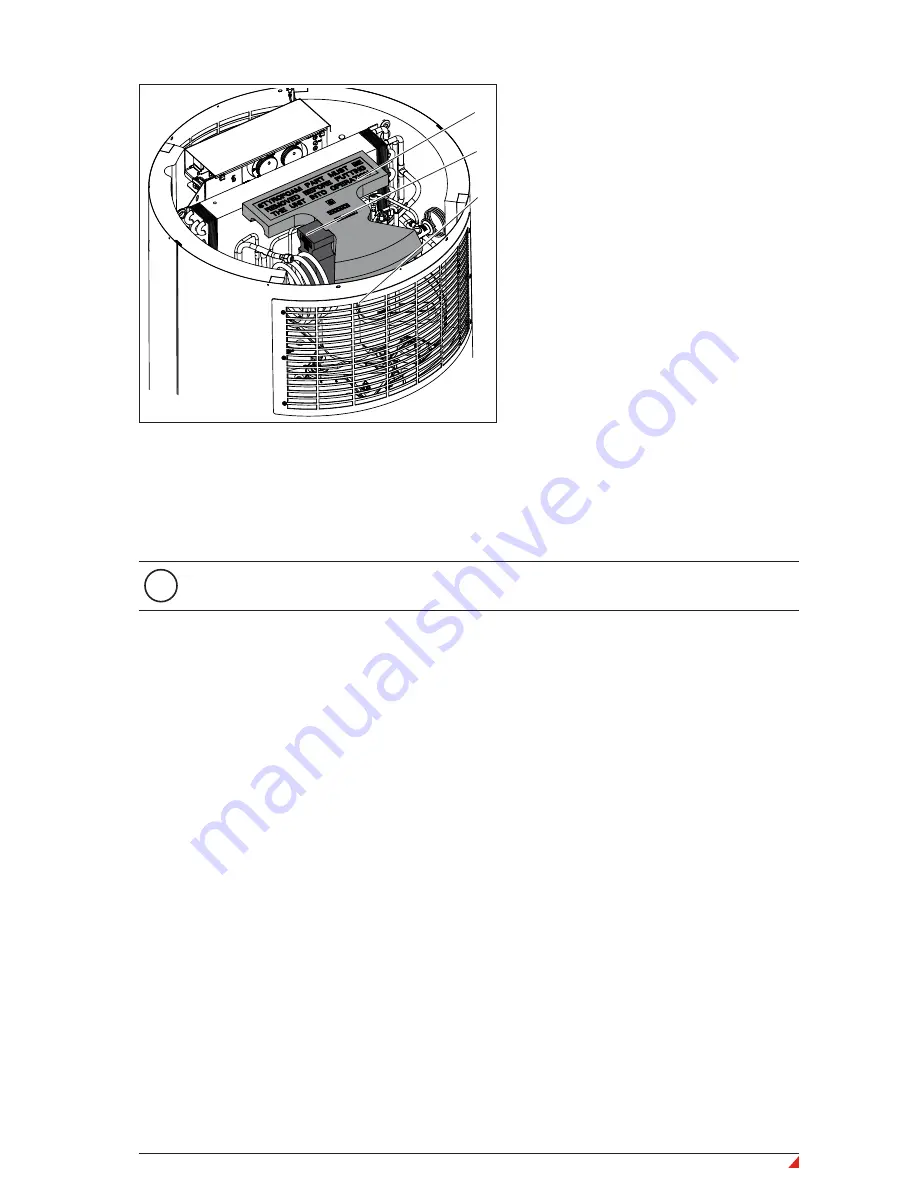

1

Transport lock part I

2

Transport lock part II

3

Air intake

f

f

Carefully remove transport lock part II by pulling it gently out of the spring of transport lock part I.

f

f

Remove transport lock part I.

f

f

Ensure that there is no packaging left in the appliance.

f

f

Check the heat pump unit for transport damage.

!

materIal loSSeS

Never commission the appliance immediately after removing the transport lock.

f

f

Fill tank with water.

f

f

Wait at least 1 hour before commissioning the appliance.

f

f

Position the appliance cover on the appliance and secure it with the screws supplied.

Summary of Contents for TIHP 300

Page 1: ...INSTALLATION INSTRUCTIONS INTEGRATEDHEATPUMP300L FOR MODEL TIHP 300 OPERATION AND ...

Page 2: ...2 INSTALLATION INSTRUCTIONS ...

Page 25: ...INSTALLATION INSTRUCTIONS 25 Notes ...

Page 26: ...26 INSTALLATION INSTRUCTIONS Notes ...

Page 27: ...INSTALLATION INSTRUCTIONS 27 Notes ...

Page 28: ...Works for you www reece com au Thermann 313698 37792 8934 ...