DOC NO. 81028

7 OF 11

Rev D 08/17/06 NJL

3

2

HEATER A

1

FUSES

208/240V

SOLENOID

CONTACTOR

1

2

3

1

2

3

T1

L1

T2

T3

L2

L3

TOUCH

PAD

PCB

POWER

SUPPLY

PCB

208/240V

J3

J7

(J6)

J2

J1

J5

J4

FLOAT

SWITCH

230 VAC

3 PHASE

TEMPERATURE SENSOR

LINE IN

LINE IN

LINE IN

208/240V COIL

RED

RED

ORN

ORN

WHT 14

RED 14

RED 14

WHT 14

BLK

6

BLK

6

BLK

6

BLK 6

BLK 6

BLK 6

SOLDERLESS

CRIMP

BLK 14

HEATER B

HEATER C

BLK 6

BLK 6

BLK 6

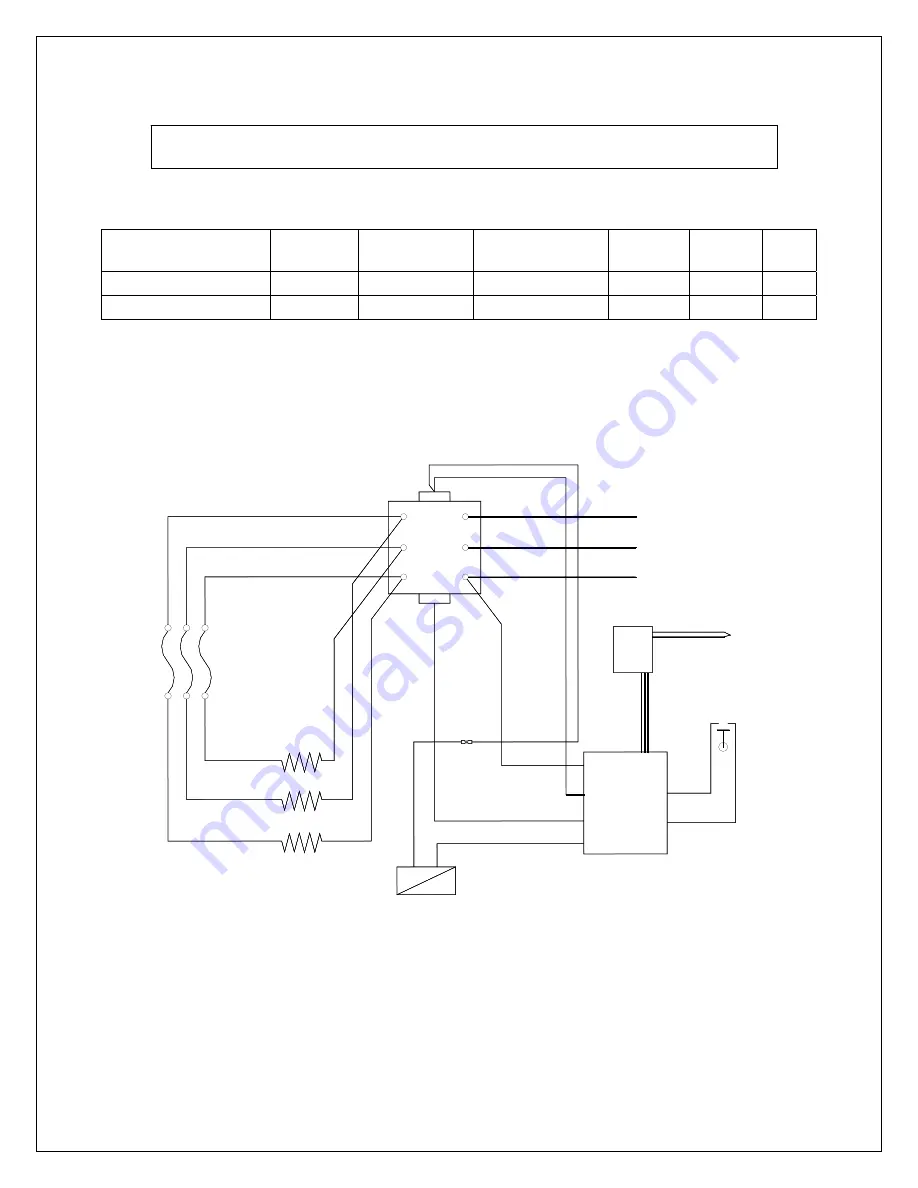

Electrical Instruction

Wire sizes recommended by National Electric code. Minimum wire temperature rating 90C.

Generator Model

Phase

Wire Gauge

Breaker Size

Fuse

Cubic

Feet

kW

5500-1203 3 4

90 50A

1200

30

5500-1503 3 4

110 60A

1500

36

1.

Turn off all electricity to the working area at the main breaker panel.

2.

Connect

230-volt A.C.

electrical lines to wire labeled 1, 2 and 3 in junction box on generator (see

Figure 2).

NOTE: All electrical wiring must be done per local electrical codes.

Figure 2